개요

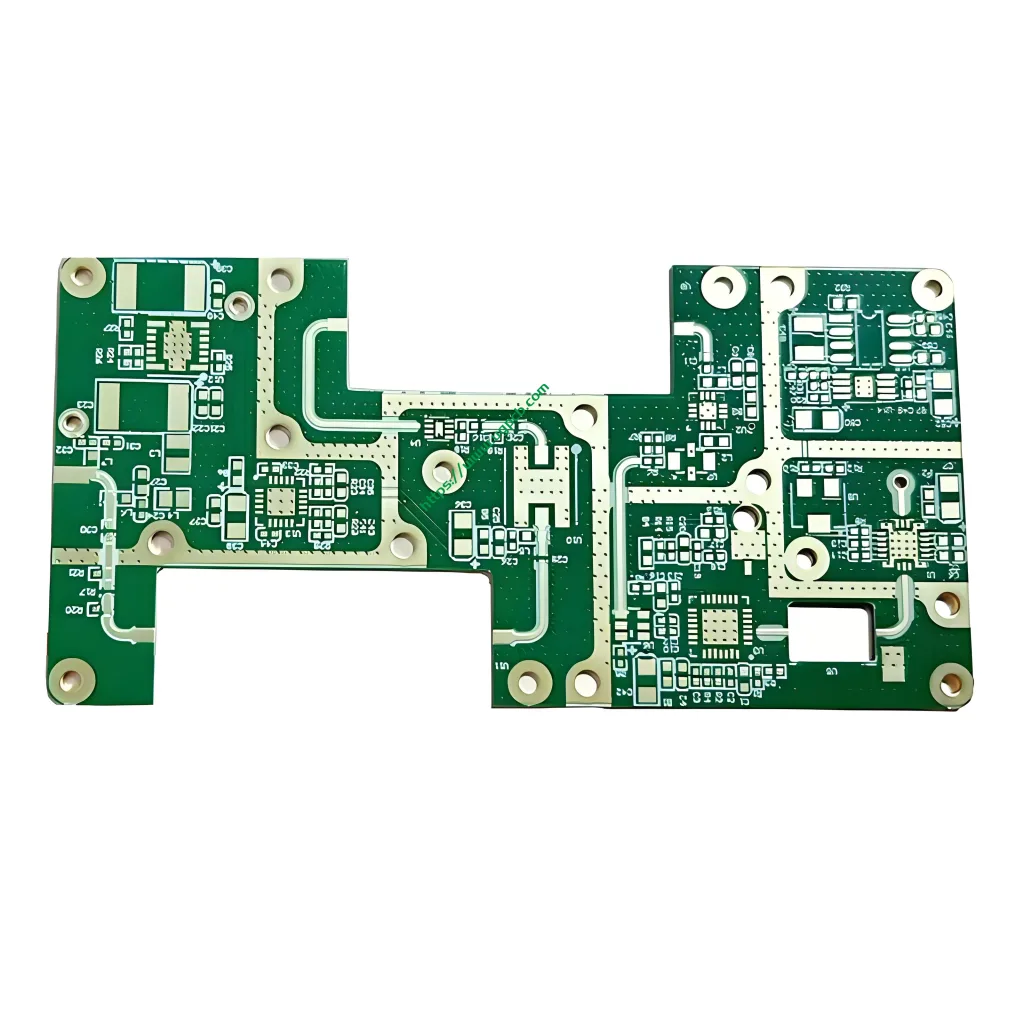

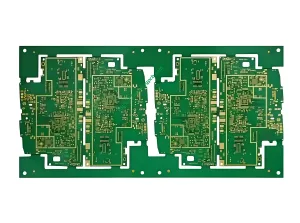

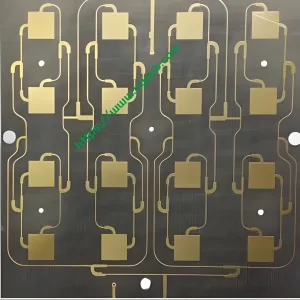

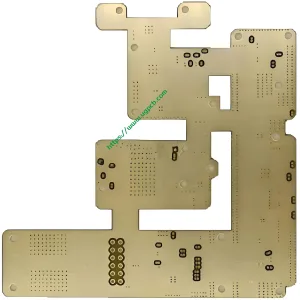

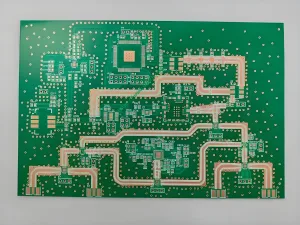

RO4350B + IT180 믹스 라미네이트 고주파 PCB. 전통적인 FR4 재료의 견고성을 Rogres RO4350B의 고급 특성과 결합, 이 4 층 PCB는 탁월한 전기 성능과 신뢰성을 제공합니다.

재료 구성

PCB는 고유 한 재료를 사용하여 구성됩니다.:

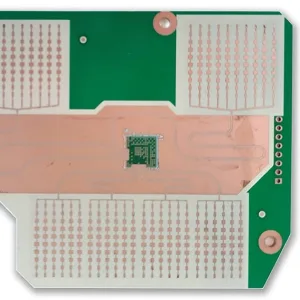

- 핵심 자료: ROGRES RO4350B, 고주파, 유전 상수가있는 저 손실 라미네이트 (DK) ~의 3.48. 이 재료는 안정성과 낮은 수분 흡수로 유명합니다., 고속 디지털 및 마이크로파 애플리케이션에 이상적입니다.

- 지원 레이어: FR4의 두 층, 표준 유리 섬유 강화 에폭시 라미네이트, 구조적 지원과 비용 효율성을 제공합니다.

레이어 구성

PCB에는 4 층 구성이 있습니다:

- 총 두께: 1.0mm

- 유전체 두께: 0.508RO4350B 층의 경우 MM

- 구리 두께: 1/0.5/0.5/1 평방 피트 당 온스 (온스), 최적의 전도성 및 전류 운반 용량 보장.

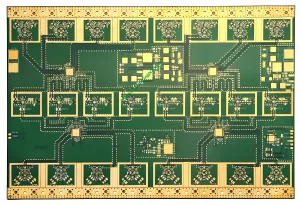

성능 특성

RO4350B + IT180 믹스 라미네이트 고주파 PCB는 몇 가지 주요 성능 이점을 제공합니다.:

- 낮은 손실: RO4350B 재료는 신호 손실을 최소화합니다, 고주파에 대한 명확하고 정확한 전송을 보장합니다.

- 안정적인 유전체 상수: 일관된 DK 3.48 온도 및 습도 변화는 신호 무결성을 유지합니다.

- 높은 신뢰성: RO4350B와 FR4의 조합은 까다로운 응용 분야에 적합한 내구성 있고 신뢰할 수있는 PCB를 제공합니다..

생산 과정

RO4350B의 생산 + IT180 믹스 라미네이트 고주파 PCB에는 여러 정밀 단계가 포함됩니다.:

- 재료 준비: RO4350B 및 FR4 재료는 크기로 절단되고 라미네이션을 위해 준비됩니다..

- 라미네이션: 균일 한 두께와 접착력을 보장하기 위해 제어 된 조건 하에서 층이 함께 결합됩니다..

- 구리 클래딩: 구리 포일은 외부 층에 적용되어 전도성 회로를 형성합니다..

- 에칭: 원치 않는 구리가 제거되어 원하는 회로 패턴을 만듭니다..

- 도금: 몰입 금 마감 처리는 구리 표면에 적용되어 전도도 및 부식 저항을 향상시킵니다..

- 최종 조립: 구성 요소가 장착됩니다, 그리고 PCB는 사양을 충족하도록 테스트되었습니다..

응용 시나리오

RO4350B + IT180 믹스 라미네이트 고주파 PCB는 다양한 통신 애플리케이션에 이상적입니다., 포함:

- 무선 통신 시스템: 기지국, 안테나, 고주파 신호 전송이 필요한 기타 구성 요소.

- 레이더 시스템: 정확한 신호 감지 및 처리를 위해 저 손실 재료에 의존하는 고정밀 레이더 장비.

- 위성 통신: 극한 환경에서 작동하고 신뢰할 수있는 장비, 고속 데이터 전송.

결론

RO4350B + IT180 믹스 라미네이트 고주파 PCB. 고급 재료와 정밀 제조의 조합은 안정적인 성능과 장기 내구성을 보장합니다..

UGPCB 로고

UGPCB 로고