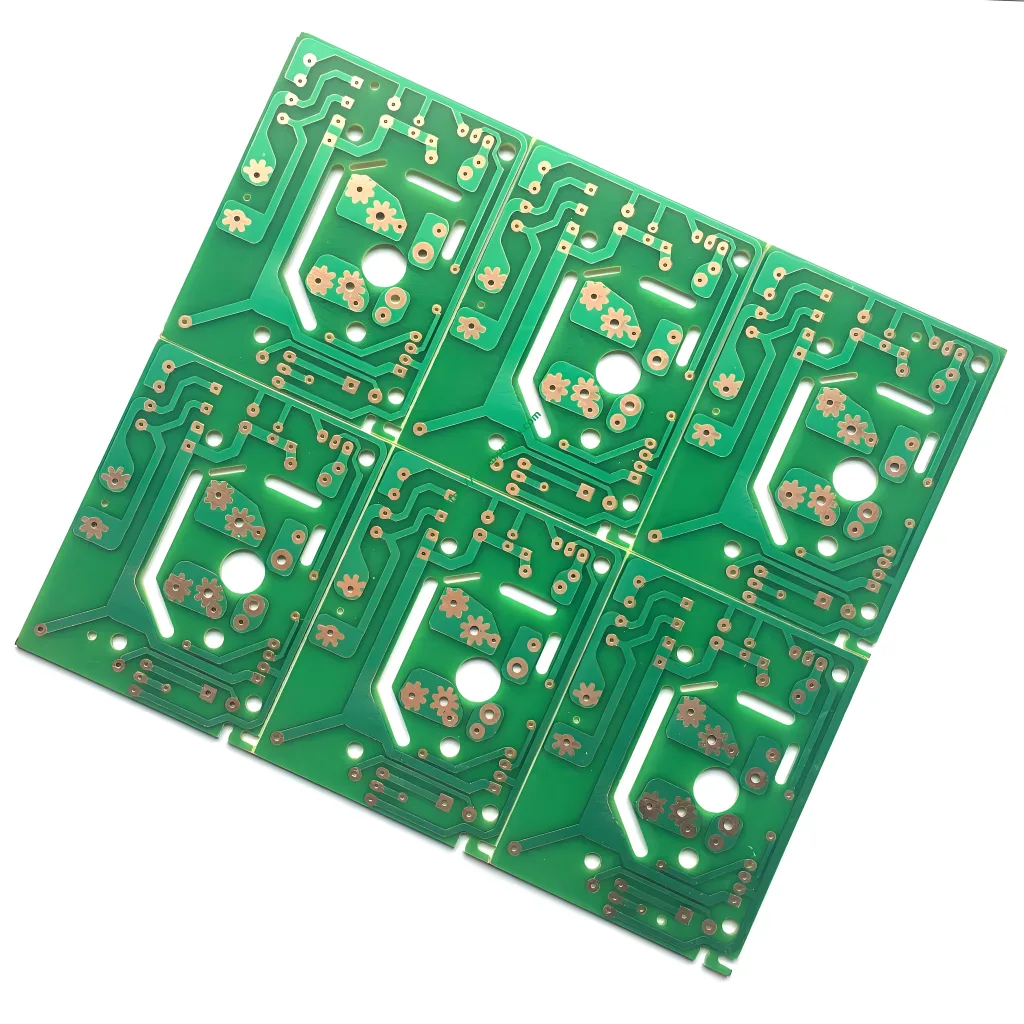

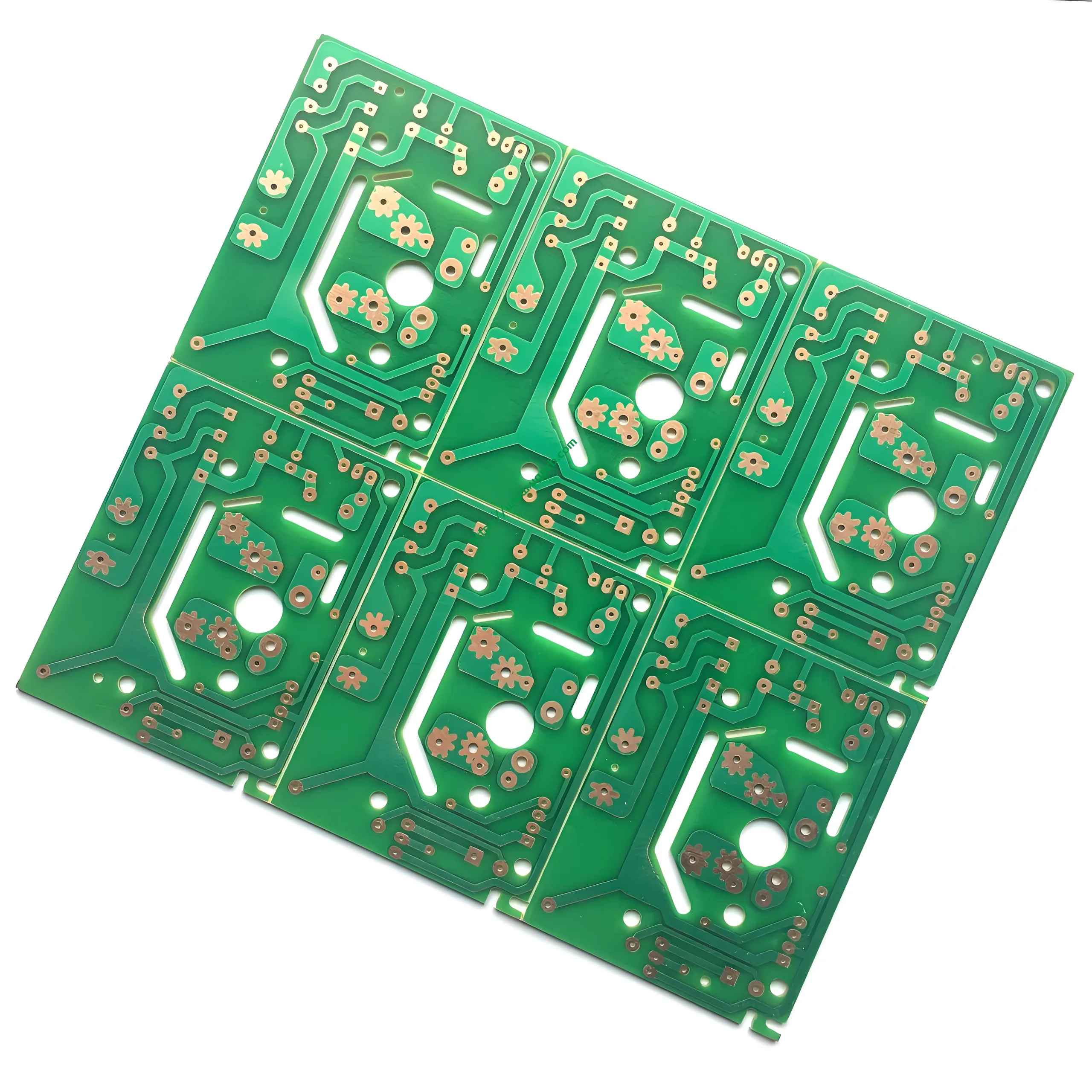

단면 PCB 개요

단면 PCB는 전자 제조의 기본 구성 요소입니다., 전자 구성 요소 어셈블리를위한 간단하면서도 효과적인 플랫폼 제공. 비전도 기판에 새겨진 전도성 구리 회로의 단일 층이 특징입니다., 복잡성이 주요 요구 사항이 아닌 다양한 응용 프로그램에 이상적입니다..

재료 구성

단면 PCB는 다양한 재료로 제작되어 다른 요구에 맞게 수용합니다.:

- CEM-1: 비용 효율성과 온화한 내구성을 위해 종이와 에폭시 수지를 결합합니다..

- CEM-3: 기계적 강도 및 전기 절연을 위해 유리 섬유 및 에폭시 수지를 사용합니다..

- FR-4: 화염 지연 특성 및 높은 유리 전이 온도로 유명합니다., 까다로운 응용 프로그램에 적합합니다.

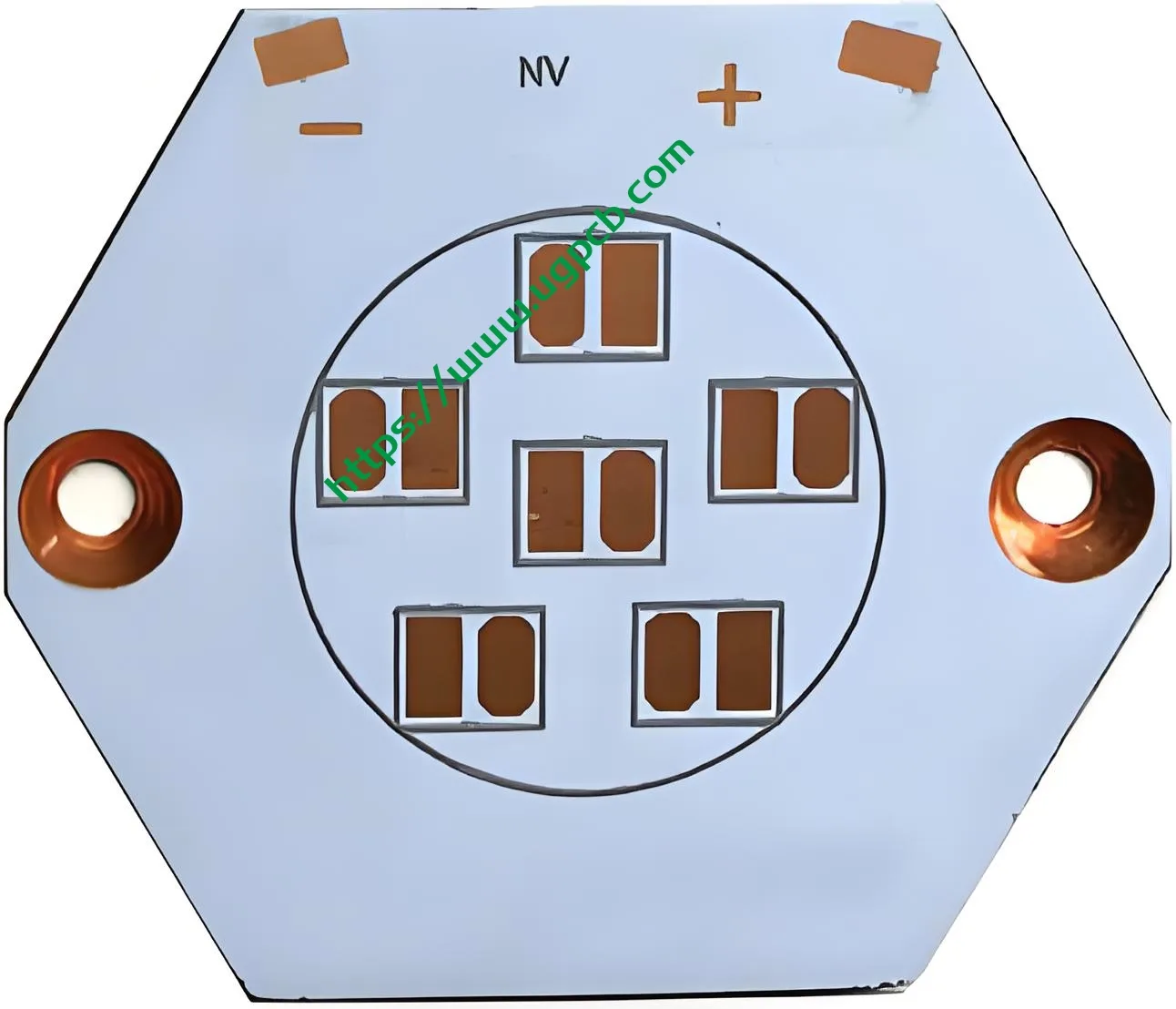

- 알류미늄 (알): 뛰어난 열전도율을 제공합니다, 고출력 회로의 열 소산에 이상적입니다.

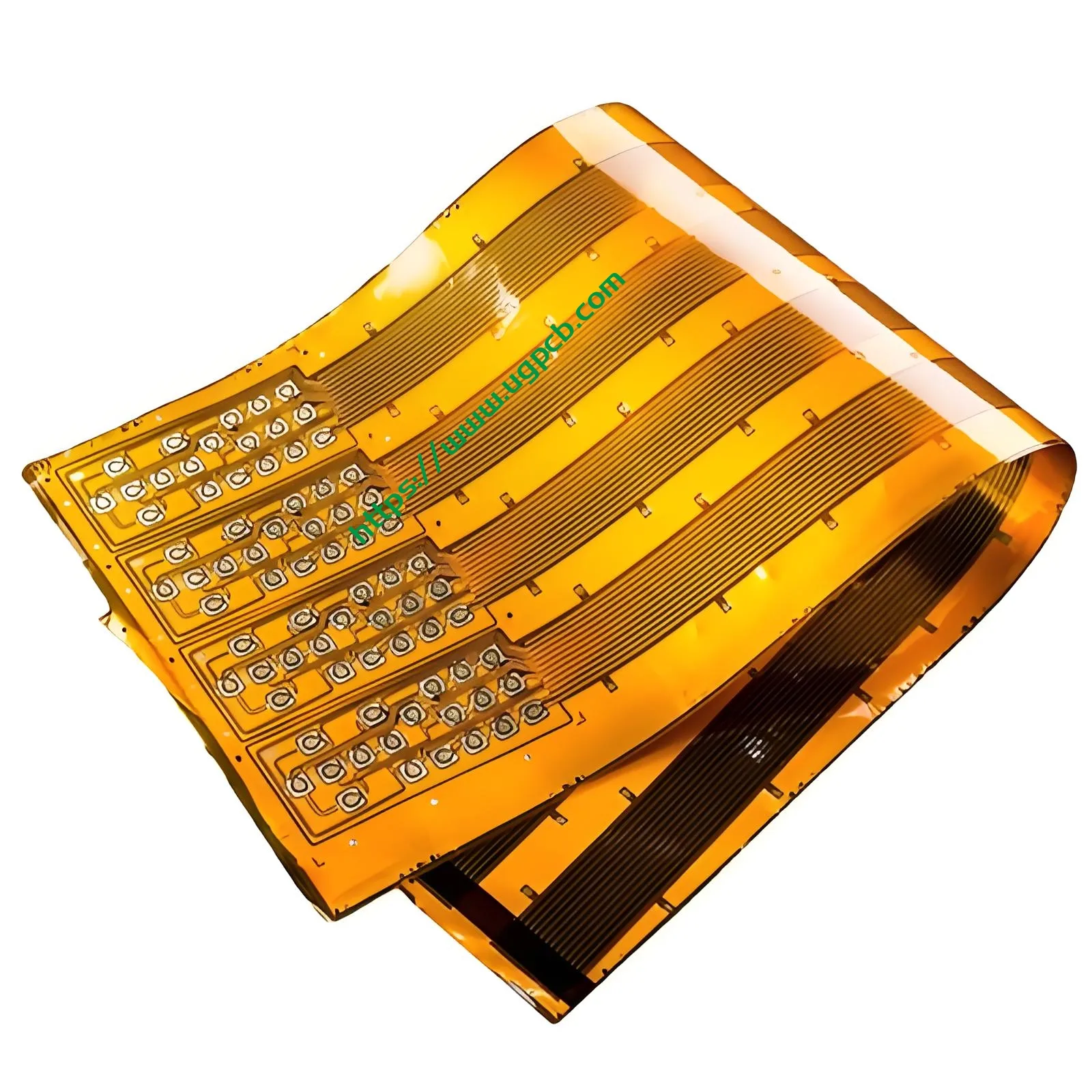

- 폴리이미드 (PI): 유연성과 내구성을 제공합니다, 굽힘 또는 적합성이 필요한 응용 분야에 적합합니다.

성능 특성

이 보드는 특정 성능 속성으로 설계되었습니다:

- 레이어 구성: 1층, 설계 및 제조 공정을 단순화합니다.

- 색상 옵션: 흰색으로 제공됩니다, 검은색, 파란색, 또는 녹색, 미적 사용자 정의를 허용합니다.

- 두께: 완성 된 두께는 0.6mm ~ 1.6mm입니다, 다양한 구성 요소 높이 및 포장 요구 사항을 수용합니다.

- 구리 두께: 0.5oz ~ 2oz의 구리 두께는 다양한 전류 운반 능력 및 회로 밀도를지지합니다..

구조 설계

구조적으로, 단면 PCB가 포함됩니다:

- 기본 재료: 구리 회로를지지하는 기판.

- 구리 포일: 회로 패턴을 형성하기 위해 에칭.

- 표면 마감: OSP (유기 용해성 보존) 처리는 양호한 용감성을 보장하고 구리를 산화로부터 보호합니다..

독특한 특징

단면 PCB를 구별하는 주요 기능에는 포함됩니다:

- 최소 추적/공간: 12mil의 최소 트레이스 및 공간은 고밀도 라우팅을 가능하게합니다, 컴팩트 한 디자인에 중요합니다.

- 표면 처리: OSP 코팅은 신뢰할 수있는 납땜 및 장기 회로 무결성을 보장합니다.

- 다재: 프로토 타입 개발 및 저용량 생산 실행 모두에 적합합니다.

생산 워크 플로

단면 PCB의 생산에는 여러 단계가 포함됩니다:

- 디자인 및 레이아웃: 회로 다이어그램은 CAD 소프트웨어를 사용하여 설계 및 배치되었습니다..

- 재료 준비: 선택된 기판 및 구리 포일이 제조된다.

- 회로 에칭: 구리 호일이 에칭되어 회로 패턴을 형성합니다..

- 교련: 구성 요소 장착 및 상호 연결을 위해 구멍이 뚫린다.

- 표면 마감: 구리를 보호하기 위해 OSP 코팅이 적용됩니다.

- 품질 관리: 보드는 사양을 충족시키기 위해 엄격한 테스트를 거쳤습니다.

- 포장 및 배송: 보드는 포장되어 고객에게 배송됩니다.

응용 시나리오

단면 PCB는 널리 사용됩니다:

- 교육 키트: 전자 제품 교육 및 학습을위한 간단한 회로.

- 프로토 타이핑: 전자 장치의 초기 단계 개발.

- 저 복잡성 장치: 다층 복잡성이 필요하지 않은 가제트 및 기기.

- DIY 프로젝트: 비용 효율적이고 간단한 PCB가 필요한 애호가 및 제조업체 프로젝트.

재료 구성을 이해함으로써, 성능 특성, 구조 설계, 독특한 특징, 생산 워크 플로, 단면 PCB의 응용 시나리오, 전자 산업에서의 다양성과 필수 역할을 이해할 수 있습니다..

UGPCB 로고

UGPCB 로고