개요

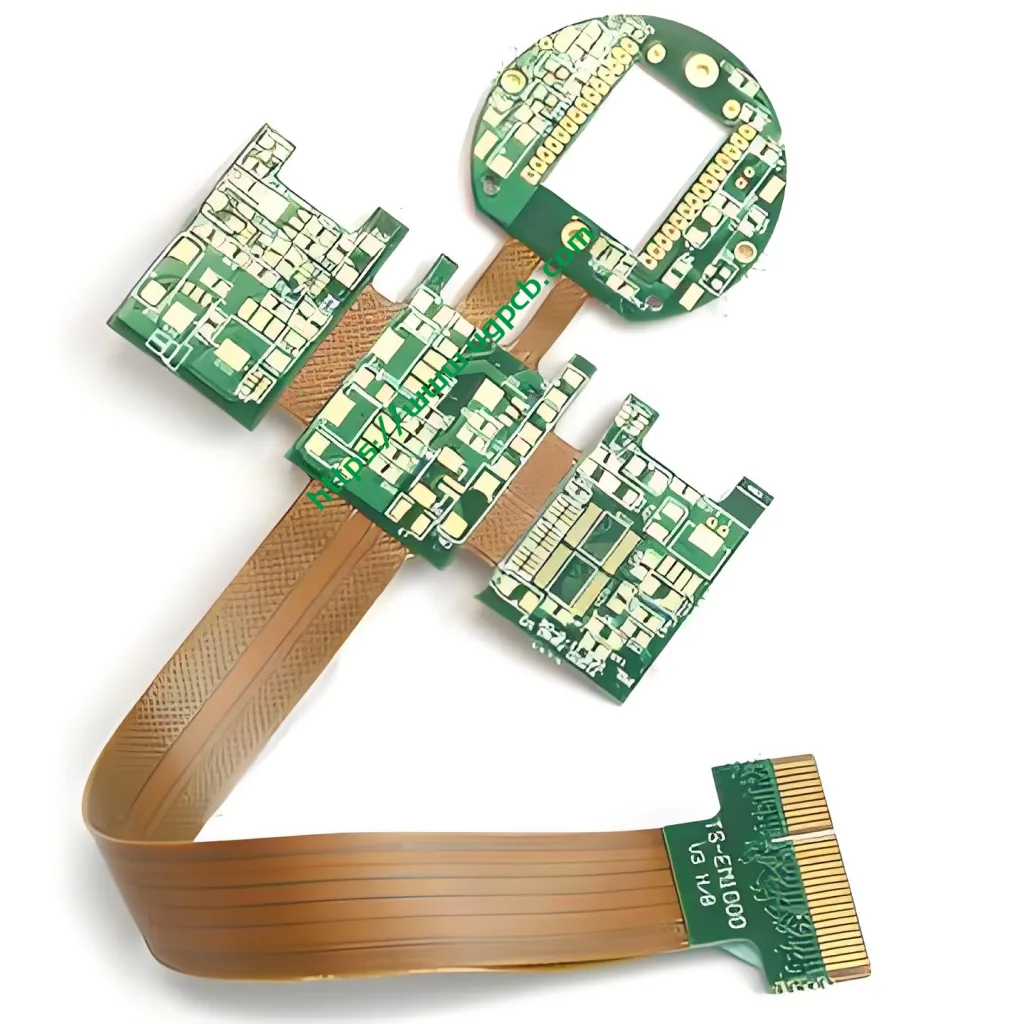

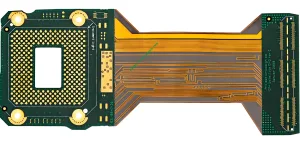

This Smart health assistant requires a smaller and thinner product to fit tightly to the body, and can detect the body’s blood pressure and heartbeat data in real time. 그러므로, 리지드 플렉스 PCB (FPCB) is required to meet the product requirements.

Rigid-Flex PCB의 장점 (FPCB)

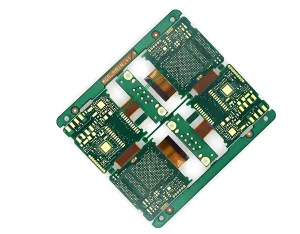

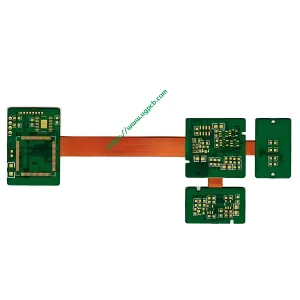

Space Savings and Cost Reduction

- It can effectively save PCB space and save the use of connectors or HotBar manufacturing process.

- Because the Rigid-Flex PCB (FPCB) is already integrated, the space that originally needed to use the connector or HotBar process can be saved.

- 고밀도 요구 사항이있는 일부 PCB의 경우, one less connector is needed.

- This also saves the cost of parts using the connector or the cost of the HotBar process.

- 게다가, the space between the two PCBs can be made tighter by eliminating the need for connectors.

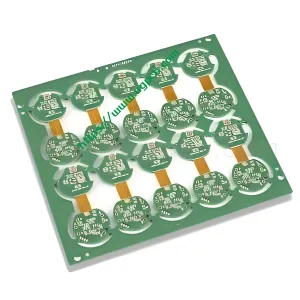

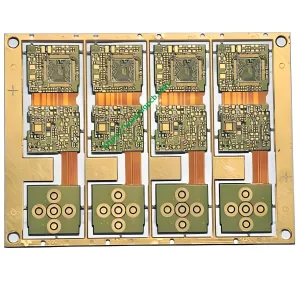

Improved Signal Transmission Reliability

- The signal transmission distance is shortened and the speed is increased, 신뢰성을 효과적으로 향상시킬 수 있습니다.

- The traditional signal transmission through the connector is “PCB-connector-FPC-connector-PCB”, while with Rigid-Flex PCB (FPCB), the signal transmission is reduced to “PCB-FPC-PCB”.

- The problem of signal transmission attenuation between different media is also reduced.

- For some Products with higher signal accuracy requirements, 리지드 플렉스 PCB (FPCB) can help improve their reliability.

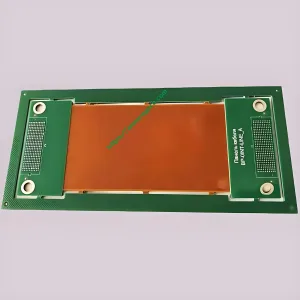

Simplified Product Assembly

- Simplify product assembly and save assembly man-hours.

- Using Rigid-Flex PCB (FPCB) can reduce the man-hours of SMT parts, because the number of connectors is reduced.

- It also reduces the man-hours for assembly of the whole machine, because it eliminates the assembly action of inserting the FPC into the connector, or eliminates the HotBar manufacturing process.

- 또한 부품 관리 및 재고 비용을 줄입니다., because the BOM is reduced, so the management becomes less.

Other Advantages

- It is flexible and can be wired three-dimensionally, and the shape can be changed according to space constraints.

- High and low temperature resistance, flame resistance.

- Foldable without affecting the signal transmission function.

- It can prevent electrostatic interference.

- Stable chemical changes, 안정, 그리고 높은 신뢰성.

- Facilitate the design of related products, reduce assembly man-hours and errors, and increase the service life of related products.

- The volume of the application product is reduced, the weight is greatly reduced, the function is increased, and the cost is reduced.

UGPCB 로고

UGPCB 로고