Teflon 고주파 전자 레인지 PCB 보드

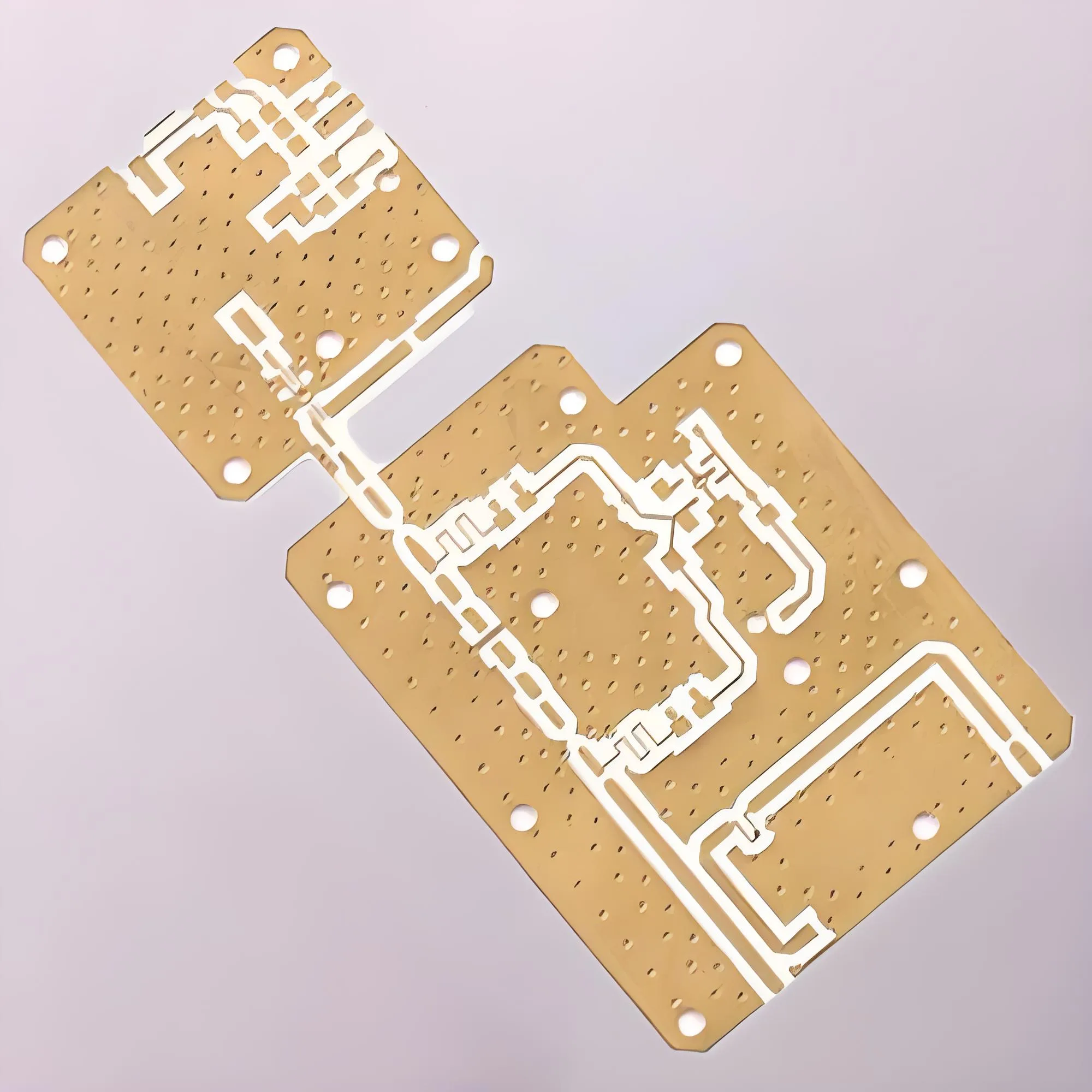

Teflon PCB에서 사용하는 PCB 재료, F4BM은 유리 직조 천으로 적층됩니다, 접착 필름, 테플론 수지 및 폴리 테트라 플루오로 에틸렌 필름, 과학적 공식과 엄격한 기술 과정에 따라. 이 제품은 전기 성능에서 F4B 시리즈에 비해 특정 이점이 있습니다. (더 넓은 범위의 유전 상수, 하위 유전 손실 탄젠트, 저항 증가, 더 안정적인 성능).

유전 상수: 2.20 2.55 2.65 3.0

차원(mm): 300*250 380*350 440*550 500*500 460*610 600*500 840*840 840*1200 1500*1000

특별한 차원,맞춤형 라미네이트를 사용할 수 있습니다.

라미네이트 두께(mm): 0.25 0.5 0.8 1.0 1.5 2.0 3.0 4.0 5.0 6.0 8.0 10.0 12.0

Teflon 고주파 전자 레인지 PCB 보드

Teflon PCB, 높은 단열, 높은 윤활, 비 접착력 및 비 독성. 하지만, 일반 FR4 보드와 비교합니다, Teflon PCB 보드는 고체 재료에서 가장 작은 표면 장력입니다., 물질을 준수하지 않습니다, 매우 작은 기계적 특성이 있습니다. 마찰 계수는 전용입니다 1 / 5 폴리에틸렌의, 이것은 Perfluorocarbon 표면의 중요한 특징입니다. 게다가, 불소 탄소 사슬의 분자간 힘으로 인해, 테플론은 끈적 거리지 않습니다, 따라서 Teflon PCB의 생산 공정에서 기판 표면을 준수하는 것은 쉽지 않습니다..

우리의 장점

1. 빠른 응답,24 온라인 서비스 시간

2. MOQ 요구 사항이 없습니다

3. 다양한 기능

4. 빠른 처리 구조 가능

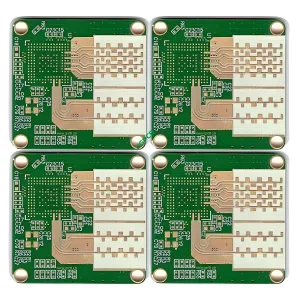

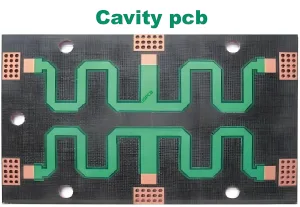

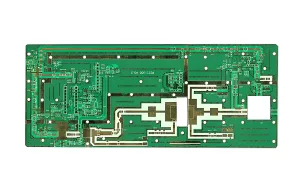

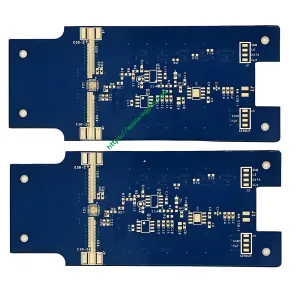

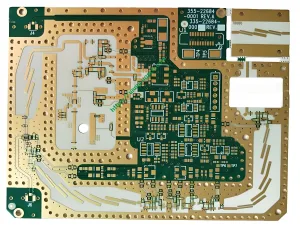

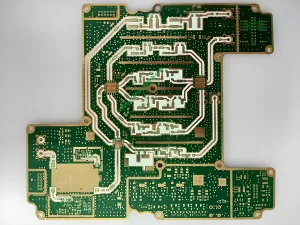

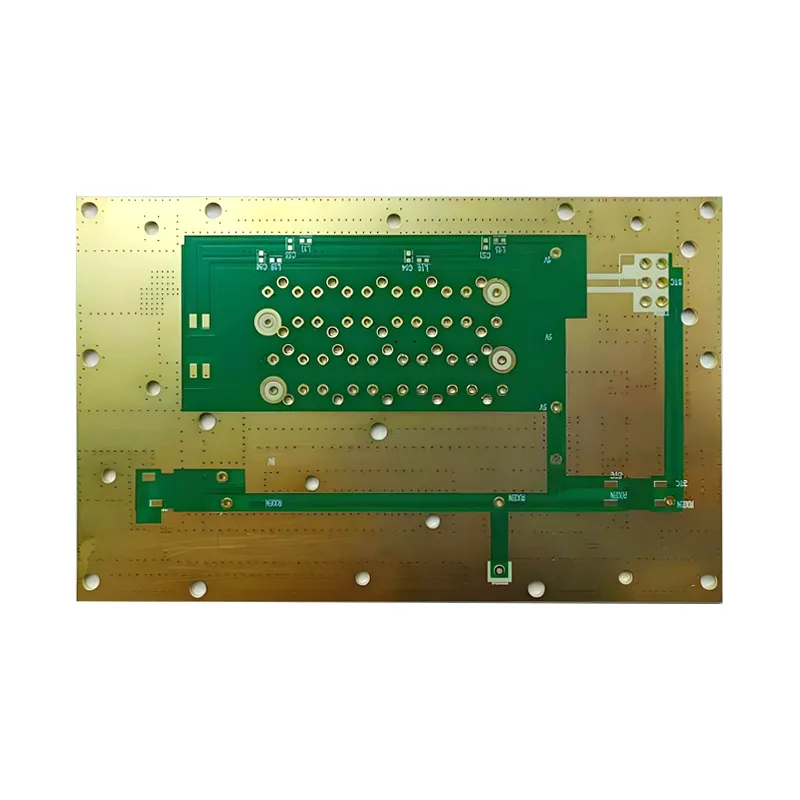

실제 프로젝트 디스플레이:

유전체 DK가 더 넓습니다, DF 각도의 접선 값이 더 낮습니다., 저항값이 증가한다, 성능이 더 안정적입니다..

RF/마이크로파 Teflon PCB 응용 프로그램

무선 주파수가있는 Teflon PCB(RF PCB) PCB 산업 내에서 점점 더 많이 사용되는 기술입니다..

–위의 작업을 수행한 고주파 RF PCB 100 MHz.

–위의 작업이 포함된 전자레인지 PCB 2 GHz 무선 주파수.

Teflon PCB는 원격 제어와 같은 다양한 응용 프로그램에서 사용됩니다.(무선 제어)보안,스마트폰,센서 등.

새로운 기술로 인해 이러한 RF 애플리케이션이 점점 더 많이 활용되고 있습니다..

이를 위해서는 높은 품질 표준에 따라 제조하고 애플리케이션에 따라 올바른 RF 재료를 선택해야 합니다..

다양한 재료의 특성을 아는 것이 중요합니다.. 올바른 자료를 선택하는 것은 아마도 Teflon PCB의 생산 과정에서 가장 중요한 결정 일 것입니다..

UGPCB 로고

UGPCB 로고