Teflon PCB의 개요

테프론 PCB, 고주파 응용 분야에서 탁월한 성능으로 유명합니다, 인쇄 회로 보드의 유형입니다 (PCB) Teflon Laminate 재료를 사용합니다. 이 재료는 우수한 유전체 특성으로 선택됩니다, 전자 레인지 및 고주파 전자 장치에 이상적입니다. Teflon PCB의 품질은 일반적으로 IPC6012 클래스 II 또는 클래스 III 표준을 준수합니다., 신뢰할 수 있고 일관된 성능을 보장합니다.

정의 및 주요 사양

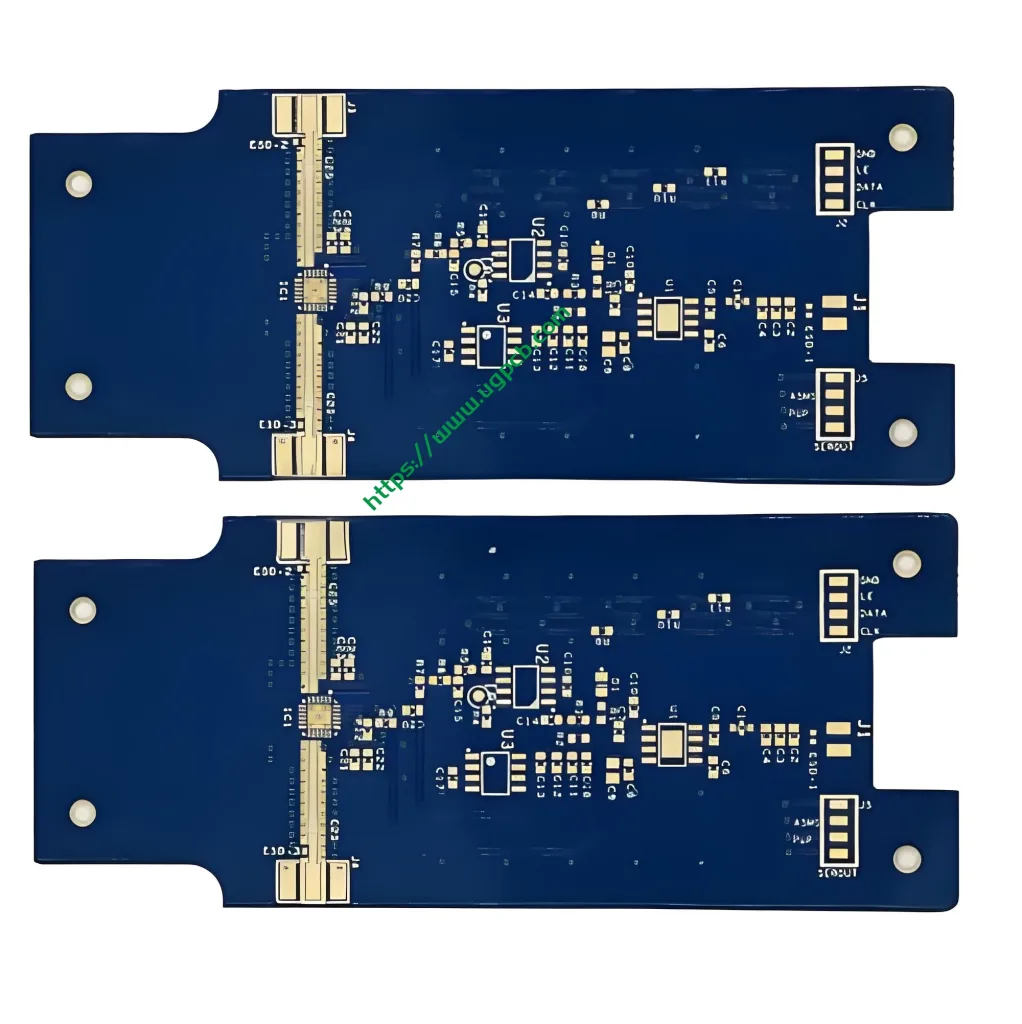

Teflon PCB는 Teflon을 유전체 재료로 사용하여 정의됩니다., 범위의 유전 상수를 제공합니다 2.0 에게 3.5. 이 보드는 범위의 레이어 수로 제조 할 수 있습니다. 2 에게 34 레이어, 회로 설계의 다양한 복잡성에 대한 유연성을 제공합니다. Teflon PCB의 두께는 0.1mm에서 12mm까지 다양 할 수 있습니다., 다양한 응용 프로그램 요구를 충족시킵니다. 구리 두께는 일반적으로 0.5oz의 염기로 시작하며 최대 1oz까지 완료 할 수 있습니다., 고주파 신호에 대한 적절한 전도도 보장.

디자인 고려 사항

Teflon PCB를 설계 할 때, 몇 가지 주요 요소를 고려해야합니다:

- 유전 상수 (DK) 소산 인자 (Df): 재료는 신호 무결성을 보장하고 고주파에서 손실을 최소화하기 위해 정확한 DK 및 DF 값을 가져야합니다..

- 층 수와 두께: 회로의 복잡성에 따라, 지정된 범위 내에서 레이어 수와 전체 두께를 조정할 수 있습니다..

- 구리 두께: 적절한 구리 두께는 낮은 임피던스를 유지하고 신호 손실을 감소시키는 데 중요합니다..

- 표면 기술: 몰입 금과 Isig와 같은 옵션 (침수은) 표면 마감 처리에 사용할 수 있습니다, 각각 전도도 및 신뢰성 측면에서 다른 이점을 제공합니다..

작동 원리

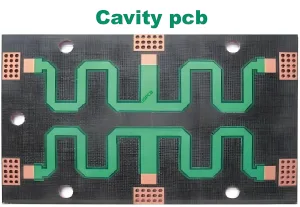

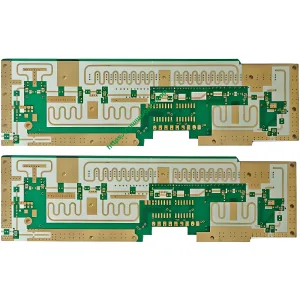

Teflon PCBS는 제어 된 임피던스의 원리 및 최소 신호 손실에 따라 작동합니다., 이는 고주파 응용 프로그램에 필수적입니다. Teflon 재료의 낮은 유전체 상수는 위상 지연 및 감쇠를 줄임으로써 신호 무결성을 유지하는 데 도움이됩니다.. 이것은 Teflon PCB가 전자 레인지 및 RF에 특히 적합하게 만듭니다. (무선 주파수) 신호 순도가 중요한 응용.

응용

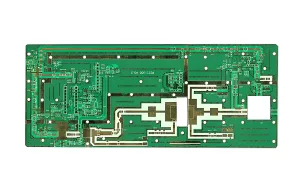

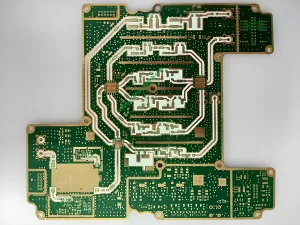

Teflon PCB의 주요 적용은 전자 레인지 및 고주파 전자 장치 분야에 있습니다.. 레이더 시스템과 같은 장치에서 사용됩니다, 위성 통신, 고성능 및 신뢰성이 가장 높은 기타 RF 구성 요소. 최소한의 손실로 고주파수를 처리하는 기능은 Teflon PCBS가 이러한 까다로운 응용 분야에 탁월한 선택입니다..

분류

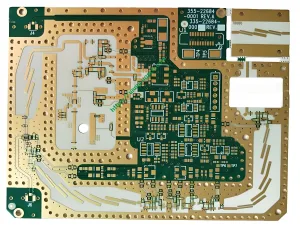

Teflon PCB는 레이어 수에 따라 분류 할 수 있습니다., 두께, 그리고 특정 응용 프로그램. 일반적인 분류에는 다음이 포함됩니다:

- 단면 및 양면 보드: 층이 적은 간단한 응용 프로그램의 경우.

- 다층 보드: 다수의 상호 연결이 필요한보다 복잡한 회로.

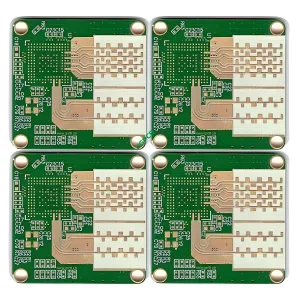

- 고주파수 특정 보드: 전자 레인지 및 RF 응용 프로그램을 위해 특별히 설계되었습니다, 종종 재료 특성 및 제조 정밀도에 대한 엄격한 요구 사항이 있습니다..

재료 특성

Teflon의 독특한 특성은 고주파 PCB에 이상적인 재료입니다.:

- 저 유전 상수: 신호 지연 및 손실을 줄이는 데 도움이됩니다.

- 온도 범위에서 안정적인 성능: 다양한 환경 조건에서 일관된 성능을 보장합니다.

- 수분 흡수에 대한 높은 저항: 수분 유입으로 인한 신호 품질의 저하를 방지합니다.

생산 과정

Teflon PCB의 생산에는 여러 단계가 포함됩니다:

- 재료 선택: 필요한 DK 및 DF 값을 기반으로 적절한 Teflon 자료 선택.

- 회로 설계: 고주파 성능을 고려하여 회로 레이아웃 생성.

- 에칭: 불필요한 구리를 제거하여 원하는 회로 패턴을 만듭니다.

- 라미네이션: 고압과 온도 하에서 여러 층을 함께 결합합니다.

- 표면 마무리: 선택한 표면 기술 적용, 몰입 금 또는 ISIG와 같은.

- 테스트 및 품질 관리: 최종 제품이 모든 사양 및 표준을 충족하는지 확인합니다.

시나리오 사용

Teflon PCB는 고주파 성능이 중요한 시나리오에서 사용됩니다., ~와 같은:

- 마이크로파 안테나: 효율적인 신호 전송 및 수신 용.

- 위성 통신: 지구와 공간 사이의 신뢰할 수있는 데이터 전송 보장.

- 레이더 시스템: 정확하고 안정적인 신호 처리 기능 제공.

결론적으로, Teflon PCB는 고주파 응용 프로그램을 위해 설계된 특수 회로 보드입니다., 우수한 유전체 특성 및 신호 무결성을 제공합니다. 그들의 디자인, 재료, 생산 공정은 마이크로파 및 RF 기술의 엄격한 요구 사항을 충족하도록 조정됩니다..

UGPCB 로고

UGPCB 로고