PTFE 세라믹 복합 기판 TFA

PTFE 세라믹 복합 유전체 기판 TFA PTFE 수지 및 세라믹의 유전체 층 조성물의 생성물의 일련, 유리 섬유 천 디핑 방법을 사용하여 조립식 시트를 만들지 마십시오., 그러나 조립식 시트를 만들기 위해 새로운 기술의 사용, 그런 다음 특별한 압박 프로세스로 눌렀습니다. 동일한 수준의 유전 상수 우수한 전기 특성으로, 열 특성, 기계적 특성, 항공 우주 등급 고주파 고주파수 신뢰성 재료입니다, 유사한 외국 제품을 대체 할 수 있습니다.

TFA 일련의 기판은 유리 섬유 천을 포함하지 않습니다., 다수의 균일 한 특수 나노 세라믹 및 수지 혼합물 사용, 전자기파 전파 유리 효과가없는 전자기파 전파, 우수한 주파수 안정성, 동일한 수준의 가장 낮은 수준의 유전 손실, 재료 x / 와이 / z 가장 낮은 이방성, 동시에 재료는 구리 포일 저 열 팽창 계수와 동일합니다., 안정적인 유전체 온도 특성.

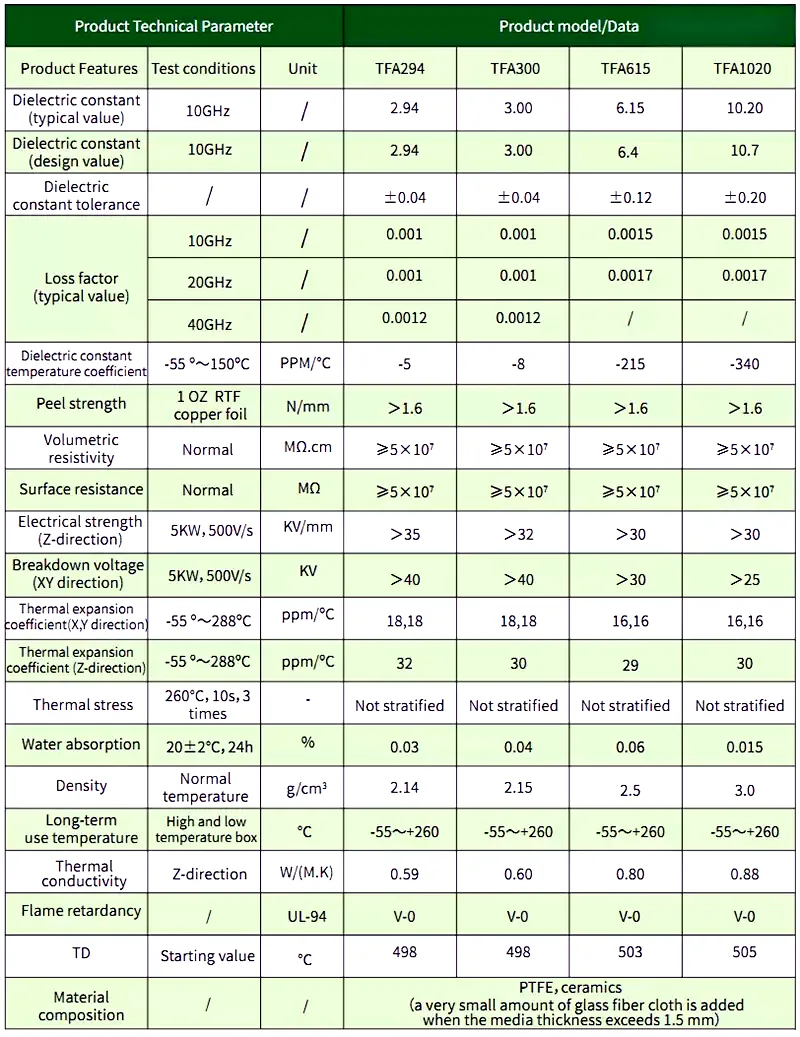

PTFE 세라믹 복합 유전체 기판 매개 변수 테이블

이 시리즈의 유전 상수는입니다 2.94, 3.0, 6.15, 10.2. TFA 시리즈는 RTF 낮은 거칠기 구리 포일과 함께 기본으로 제공됩니다., 탁월한 껍질 강도를 제공하면서 도체 손실을 줄입니다.

TFA294 및 TFA300은 묻힌 50Ω 저항성 구리 포일과 일치하여 저항 필름 시트를 형성 할 수 있습니다.. 회로 보드는 표준 PTFE 시트 기술로 처리 할 수 있습니다.. 시트의 우수한 기계적 및 물리적 특성은 다층에 적합합니다., 높은 다층 및 백플레인 처리; 동시에, 밀도가 높은 구멍 및 미세한 라인 처리에서 탁월한 가공성을 보여줍니다..

PTFE 세라믹 복합 유전체 기판 TFA 시리즈

TFA 시리즈 제품 기능

작은 유전성 상수 공차 및 우수한 배치 투 배치 일관성;

클래스에서 가장 낮은 유전체 손실;

밀리미터 파 및 자동차 레이더 응용 분야의 경우 최대 77g의 주파수 사용;

우수한 주파수 안정성 및 위상 안정성 -55 ° C ~ 150 ° C;

우수한 조사 저항, 용량 조사 치료 후 안정적인 유전체 및 물리적 특성 유지;

아웃소싱 성능이 낮습니다, 진공 조건 하에서 재료 변동성 성능의 표준 방법에 따라 테스트, 항공 우주 응용 프로그램에 대한 진공 유출 요구 사항을 충족합니다;

우수한 열 팽창 계수, 구리 호일과 동일합니다; 구리 구멍의 신뢰성 및 치수 열 안정성을 보장합니다.;

낮은 수분 흡수, 습한 환경에서 재료의 안정성을 보장합니다.

TFA 시리즈 전형적인 응용 프로그램

항공 우주 장비, 공간, 캐빈 내 장비, 항공기

마이크로파, 안테나, 위상에 민감한 안테나

조기 경보 레이더, 공중 레이더 및 기타 종류의 레이더

단계적 배열 안테나, 빔파 네트워크

위성 통신, 항해

전원 진폭

UGPCB 로고

UGPCB 로고