S1150GH features

– Lead-free compatibility and excellent ion migration resistance

– 낮은 z 축 열 팽창 계수

– Halogen-free PCB, antimony-free, red phosphorus free, and no other highly toxic and residual toxic components during waste combustion

– Applicable to high-end HDI performance processing requirements

S1150GH application field

– 가전제품

– 스마트폰, 정제, 노트북

– 주도의, Game device

S1150GH PCB Material

Halogen-free PCB Material Shengyi S1150GH

Halogen-free PCB material of Shengyi S1150G.

PCB material for halogen-free high reliability multilayer board: S1150GH+prepreg: S1150GHB PCB manufacturing precautions

1. S1150GH/S1150GHB storage conditions

1.1 S1150GH/S1150GHB copper clad plate

1.1.1 저장 방법

Put it on the platform or suitable rack in the original packaging form to avoid heavy pressure and prevent deformation of the plate caused by improper storage.

1.1.2 스토리지 환경

판은 환기에 보관해야합니다, 직사광선을 피하기 위해 건조 및 실내 온도 환경, rain and corrosive gas erosion (the storage environment directly affects the plate quality). Double panels should be stored in a suitable environment for two years, and single panels should be stored in a suitable environment for one year. 내부 성능은 IPC4101 표준의 요구 사항을 충족 할 수 있습니다..

1.1.3 작업

Wear cleaning gloves to handle the plate carefully. 충돌, 슬라이딩, 등. 구리 호일이 손상됩니다, 그리고 베어 핸드 작동은 구리 호일 표면을 오염시킵니다.. 이러한 결함은 플레이트 사용에 부정적인 영향을 줄 수 있습니다..

1.2 반 경화 시트

1.2.1 저장 방법

Store horizontally in the original packaging form to avoid heavy pressure and damage of the semi curing sheet caused by improper storage. The remaining roll shaped semi curing sheet after cutting shall be sealed and packed with fresh film and put back on the bracket in the original packaging.

1.2.2 스토리지 환경

Prepreg는 자외선이없는 환경에 밀봉 된 패키지에 저장되어야합니다.. 특정 스토리지 조건 및 스토리지 기간은 다음과 같습니다.

상태 1: 온도<23 ℃, 상대 습도<50%, 저장 기간 3 달,

상태 2: 온도<5 ℃, 저장 기간 6 달,

The relative humidity has a great influence on the quality of the prepreg, and the corresponding dehumidification treatment should be carried out in humid weather. It is recommended to use the prepreg within 3 days after unpacking.

1.2.3 절단

It is better for professionals to wear clean gloves for cutting to prevent the surface of the prepreg from being polluted. Prepreg가 주름이나 주름을 방지하기 위해 조작이 조심해야합니다.. When PP is cut, the worktable should be cleaned first to avoid cross contamination of different types of PP resin powder.

1.2.4 지침

Prepreg가 냉장 저장에서 꺼낼 때, 패키지를 열기 전에 온도 복구 과정을 거쳐야합니다.. 온도 회복 시간은 그 이상입니다 8 시간 (특정 저장 조건에 따라). The package can be opened after the same temperature as the ambient temperature. The prepreg that has been opened into sheets must be stored in Condition 1 또는 조건 2 그리고 가능한 빨리 사용했습니다. After more than 3 날, 지표가 자격을 갖춘 후에 다시 확인하고 사용해야합니다.. After the roll shaped prepreg is opened, the remaining roll shaped mantissa shall be used, It is required to carry out sealed packaging of the original packaging degree and store it in Condition 1 또는 조건 2. IQC 검사 계획이있는 경우, the prepreg shall be tested as soon as possible after receipt (더 이상 5 날) IPC-4101 표준에 따르면. If the prepreg is dehumidified before use, it is recommended to set the conditions for the dehumidification cabinet: 온도<23 ℃, relative humidity about 40%, and the upper limit of fluctuation shall not exceed 50%.

2. S1150GH/S1150GHB PCB processing suggestions

2.1 절단

절단에 톱질 기계를 사용하는 것이 좋습니다, 이어서 전단기가 이어집니다. Note that cutting with roller knife may cause plate edge delamination, so as to avoid plate edge delamination due to tool wear and improper clearance.

2.2 코어 플레이트 베이킹

According to the actual use situation, the core plate can be baked. If the core plate is baked after opening, it is recommended that the core plate be baked after a high-pressure water wash after opening to avoid the introduction of resin powder produced during the shearing process to the plate surface, 에칭이 좋지 않을 수 있습니다. It is recommended that the core plate be opened and baked at 150 ℃/2~4h. 플레이트는 열원에 직접 접촉 할 수 없습니다..

2.3 Browning of inner layer

S1150GH scheme is suitable for browning process.

2.4 스태킹

스태킹 프로세스는 본딩 시트의 스택 시퀀스가 일관되도록해야합니다., and the overturning action shall be avoided during the stacking process to reduce the problems such as warping, deformation and folding caused thereby.

The time from browning of core plate to pressing plate shall be controlled within 12 시간. When the buffer material may have moisture absorption risk, it is recommended to dry it.

Due to the material characteristics, it is easy to carry static electricity. When stacking, pay special attention to the adsorption of foreign matters on PP.

In order to ensure good alignment effect of expansion and contraction during plate arrangement, it is recommended to use rivet riveting for fixation. If fusion is required, it is recommended to use electromagnetic heat fusion. 동시에, the best fusion effect parameters should be evaluated in detail. For other fusion methods, the PCB’s own conditions should be carefully evaluated for fusion effect to avoid layer deviation caused by poor fusion.

2.5 라미네이션

It is recommended to select the press plate with good vacuum pumping performance and vacuum valve sealing to avoid the entry of external moisture.

The recommended heating rate is 1.5~2.5 ℃/min (the material temperature is within the range of 80~140 ℃).

It is recommended that the laminating pressure be 350-430psi (유압 프레스). The specific high pressure should be adjusted according to the structural characteristics of the plate (Prepreg의 수와 접착제 충전 영역의 크기). It is recommended to turn to high pressure at 80-100 ℃.

Curing conditions: 온도 180 ℃, time more than 60min.

Cooling rate < 2 ℃/min.

The material temperature of hot pressing is less than 150 ℃.

If copper foil heat conduction press is used, Shengyi Company shall be informed in advance.

단열 보드 또는 단일 패널이 다층 보드에서 사용되는 경우, 절연 보드 또는 단일 패널은 너무 부드러운 절연 보드로 인한 불충분 한 결합력을 피하기 전에 사용하기 전에 거칠어 야합니다., 또는 양면 보드를 생산을 위해 단일 패널 또는 절연 보드로 에칭 할 수 있습니다..

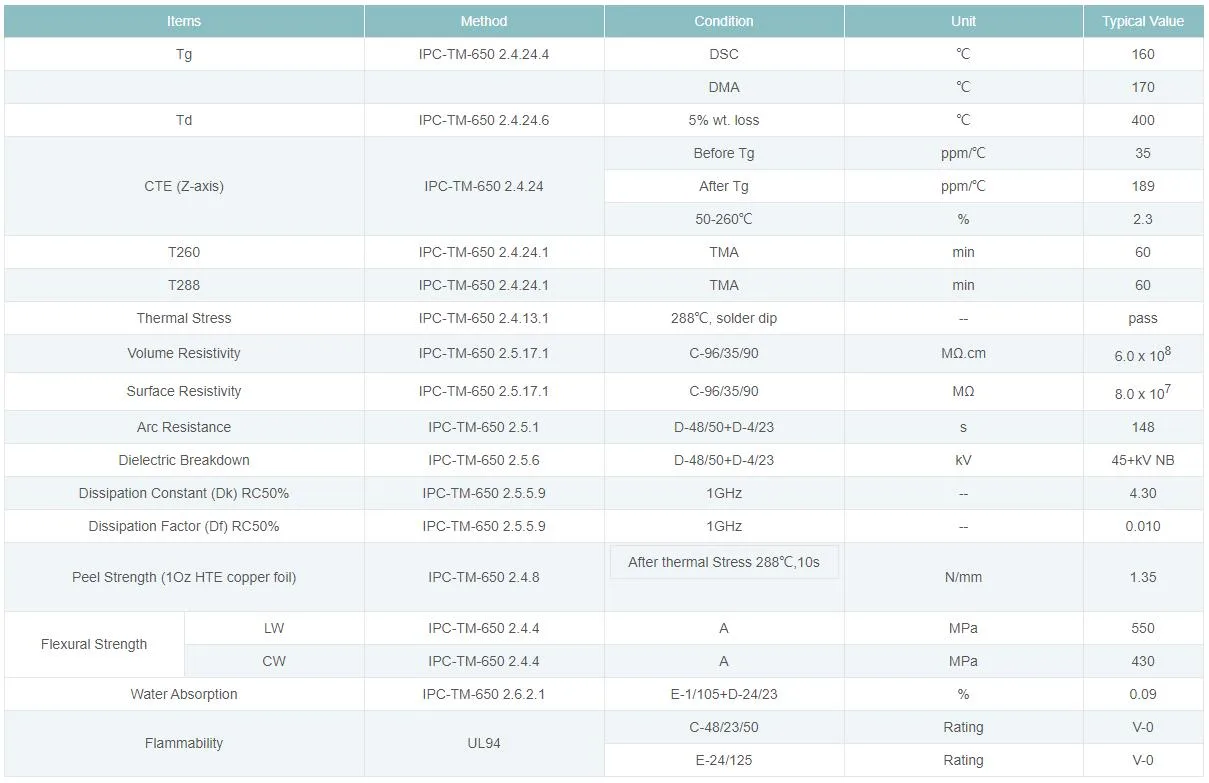

Shengyi S1150G Halogen-Free PCB material Specifications Table

2.6 교련

It is better to use a new drill.

The stack thickness is recommended to be no more than 2 pieces/stack (calculated as per the plate thickness of 1.6mm/block).

It is recommended to limit the drilling hole to 1000-2000 holes.

The feed rate for drilling shall be 15-20% lower than that for processing ordinary FR-4 materials.

2.7 Drying plate after drilling

It is suggested that the drying conditions after drilling should be 170-180 ℃/3h. Note that the plates should not be in direct contact with the heat source.

Baking before resin plug hole after back drilling: 170-180 ℃/2-3h.

2.8 Dirt removal

It is suggested that the specific parameters should be set according to the actual PCB structure (board thickness, aperture size), and all kinds of structural boards should be fully evaluated in detail to determine the best matching glue removal conditions and parameters. The glue removal effect should refer to the fact that there is no resin residue at the copper junction of the inner layer. The horizontal Desmear or vertical Desmear is recommended. The specific glue removal conditions are related to the equipment, liquid medicine model, board thickness or hole area. Under the premise of full load, the thicker the board is recommended, The longer the degumming time is.

2.9 Solder resistance ink

It is recommended that the drying plate before green oil: 130 ℃/2-4h,

베이킹에 랙을 사용할 때, 랙을 삽입 할 때 플레이트가 압착되거나 변형 된 경우, 베이킹 후에 뒤틀림이 발생합니다. It is not recommended to back wash the solder resist ink, which may cause white spots.

2.10 주석 스프레이

It is suitable for lead-free tin spraying process. For the structure of thick copper and large copper surface on the outer layer (or thick copper plating), the temperature is high during lead-free tin spraying, resulting in excessive thermal stress, which is prone to white spots between large copper surfaces, copper skin warping and other problems. The improvement measures are as follows:

1. Try to reduce the tin spraying temperature, shorten the tin spraying time, and reduce the thermal stress generated during tin spraying,

2. Before tin spraying, pre bake the plate under the condition of 140-150 ℃/2h, and spray tin immediately to remove the moisture accumulated on the plate surface, which can reduce the probability of white spots,

3. Avoid too large tin spraying surface, or increase the thickness of green oil appropriately, which can well cushion the thermal stress generated during tin spraying,

4. The large copper surface structure is designed as a grid structure.

2.11 프로필 처리

It is recommended to use a milling machine for processing and reduce the traveling speed appropriately. It is not recommended to use a beer plate for processing.

2.12 포장

It is recommended to bake the plate before packaging under the condition of 120 ℃/4-6h to avoid heat resistance degradation caused by moisture. Aluminum foil vacuum packaging is recommended.

3. S1150GH/S1150GHB welding

3.1 포장 유효성

It is recommended to use vacuum aluminum foil bags for packaging, and the recommended period of validity is 3 달. 구성 요소를 굽는 것이 좋습니다 120 ℃ for 4~6h before assembly.

3.2 S1150GH/S1150GHB reflow welding parameters

Suitable for conventional lead-free reflow soldering process.

용접 온도는 350 ~ 380 °입니다 (using temperature controlled soldering iron),

단일 용접 지점의 용접 시간: 이내에 3 초.

UGPCB 로고

UGPCB 로고