Introduction

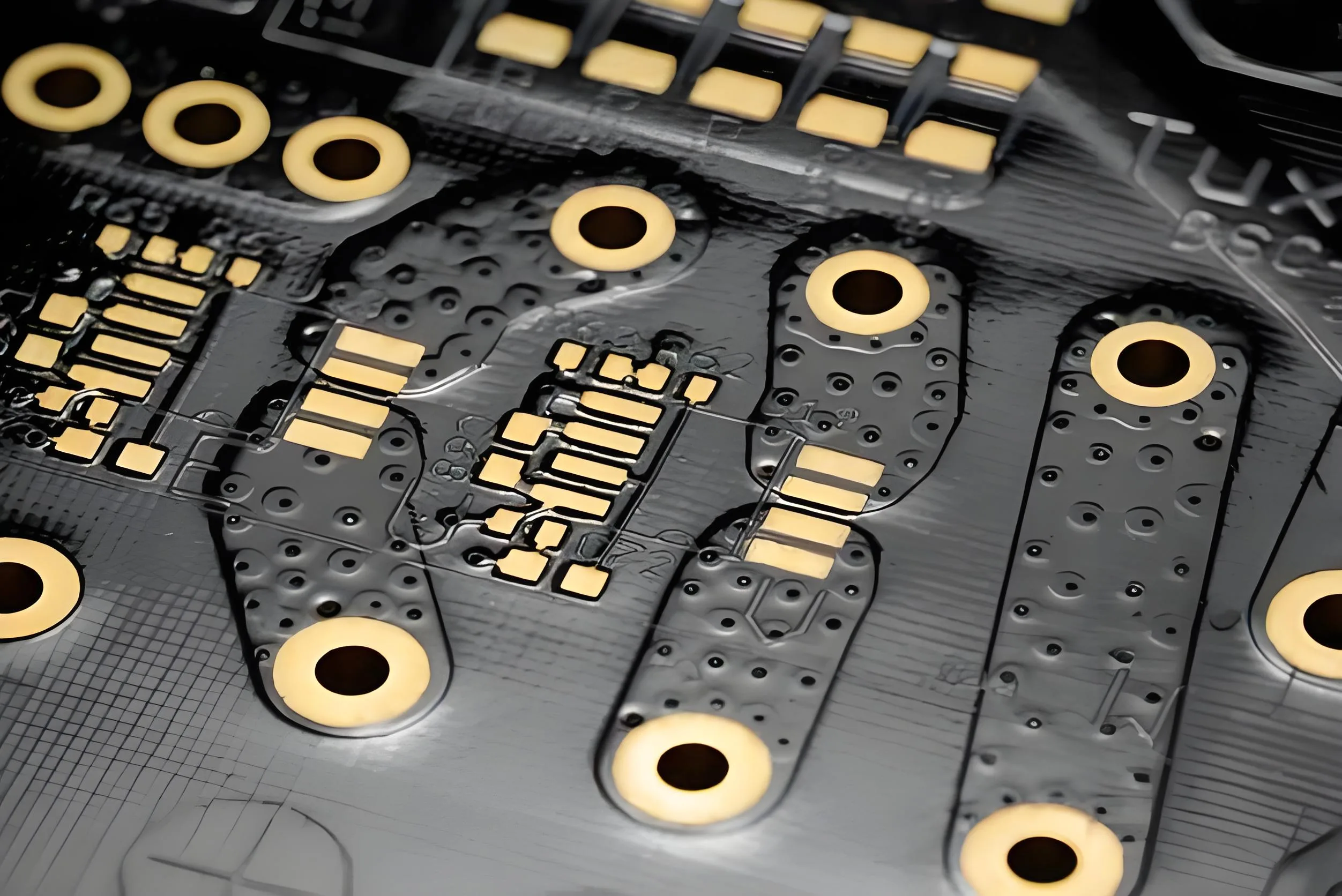

In high-end PCB manufacturing, drilling precision directly impacts signal integrity and reliability. Industry data reveals that 38% of micro-via defects below 0.15mm originate from non-circular hole imperfections (IPC-6012E standard). This study establishes a kinematic model combined with Python simulations to decode polygonal hole formation mechanisms, providing theoretical support for process optimization.

I. Kinematic Modeling: Where Mechanical Ballet Meets Mathematical Principles

Dual-Motion Coupling Mechanism

The drill bit’s composite motion comprise

- Revolution: Rotational motion around the theoretical axis at angular velocity ω_p

- Rotation: Spinning around its own axis at angular velocity ω_s

Coordinate System Analysis

Coordinate System Analysis

A right-handed O-XYZ coordinate system is established with the Z-axis as the theoretical drilling centerline. Key parameters:

- R = 5 mm (revolution radius)

- r = 1 mm (rotation radius)

- ω_p = 2 rad/s

- ω_s = 3 rad/s

- Phase angle φ = π/6 (3° deviation causes 2μm aperture variation per empirical data)

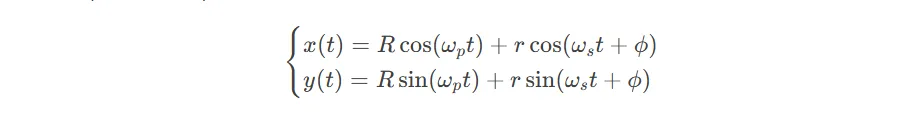

Motion Equation Derivation

The drill tip’s absolute position vector combines both motions:

Rational angular velocity ratios (e.g., ω_p/ω_s = 2/3) generate closed trajectories, forming pentagonal holes.

II. Python Simulation: Digital Twin Reveals Morphological Evolution

Parametric Modeling

# Dynamic parameter configuration params = { 'R': np.linspace(3,7,5), # Revolution radius gradient 'r': [0.8,1.0,1.2], # Rotation radius combinations 'ω_ratio': [(2,3),(3,4),(5,7)] # Angular velocity ratios }

Characteristic Pattern Analysis

Parameter scanning reveals:

- Integer ratios (ω_p/ω_s ∈ ℤ): Concentric circular trajectories (Fig. 3a)

- Coprime ratios (m/n where m,n ∈ ℤ): n-sided polygonal trajectories (Fig. 3b)

- Irrational ratios: Quasi-periodic trajectories (Fig. 3c)

III. Process Optimization: Bridging Theory and Practice

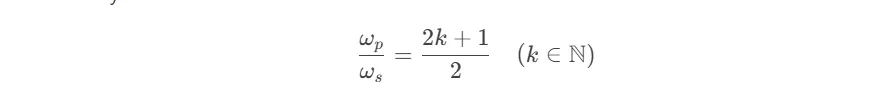

Golden Angular Velocity Ratio Principle

Fourier analysis recommends:

A leading PCB manufacturer reduced polygonal defects from 1.2% to 0.3% using this principle (2023 quarterly report).

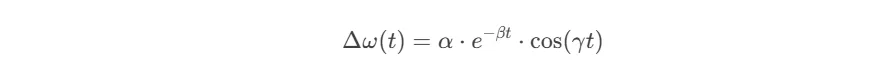

Dynamic Compensation Technology

Introducing acceleration correction:

Compensation reduced hole roundness error from 8μm to 2.5μm in 6-layer HDI boards (ISO 286-2 standard).

IV. Future Perspectives: Intelligent Drilling Era

Digital Twin Systems

Integrated ANSYS Maxwell electromagnetic simulations enable thermal-mechanical-electrical multiphysics coupling.

AI-Driven Parameter Optimization

Deep reinforcement learning model:

Q(s,a)=E[Rt∣st=s,at=a]

Experimental results show AI reduces process debugging cycles by 70% (research institute data).

Conclusion

Through kinematic modeling and digital simulation, this study not only elucidates polygonal hole formation mechanisms but also pioneers intelligent drilling paradigms. With surging demand for 5G high-frequency PCBs (Prismark forecasts $89.2B global market by 2025), this “mathematics-driven manufacturing” approach will redefine industry competitiveness.

UGPCB LOGO

UGPCB LOGO