Resin Plug for PCB

In the vast universe of electronic manufacturing, Printed Circuit Boards (PCB) undoubtedly stand as the brightest stars, carrying the heart and soul of electronic devices. Among the myriad processes involved in PCB manufacturing, one that may seem simple yet is critically important is PCB resin plugging. This process quietly safeguards the reliability and stability of circuit boards. This article will take you on a deep dive into this technique, unveil its mysterious veil, and appreciate its unique charm in electronic manufacturing.

I. PCB Resin Plugging: The Origin of the Process

PCB resin plugging, as the name suggests, involves precisely injecting resin material into the through-holes of PCBs to effectively seal these openings. The purpose of this process is to prevent solder paste from seeping through the holes to the back of the board, thereby avoiding the risk of short circuits. Compared to traditional ink plugging, resin materials (Epoxy) have become the ideal solution due to their superior reliability, process adaptability, and material properties.

Ⅱ.The Process Flow: A Combination of Precision and Art

PCB Resin Plugging Machine Equipment

1.Hole Treatment

Early resin plugging processes did not involve complex hole treatment steps. However, with the increasing application of PCBs in high-temperature environments and the continuous reduction of the Coefficient of Thermal Expansion (CTE) of boards, the mismatch between the expansion coefficient of resin and the board material has gradually become apparent. To address this issue, modern processes include roughening or micro-etching steps for hole walls to enhance the bonding strength between resin and board material, reducing the risk of resin separation from hole walls.

2.Plugging

The industry generally adopts screen printing for plugging operations. However, for high-demand products such as automotive and aviation electronics, vacuum plugging equipment is preferred. Horizontal and vertical vacuum plugging machines each have their characteristics; the former is suitable for large area, uniformity-requiring tasks, while the latter is better suited for small area, high-precision plugging jobs.

3.Baking

After plugging, a high-temperature baking process at 150 degrees Celsius for 1 hour is necessary to ensure the resin fully cures and forms a stable insulating layer. This step is crucial for ensuring the quality of the plugging and allowing the resin material to perform optimally.

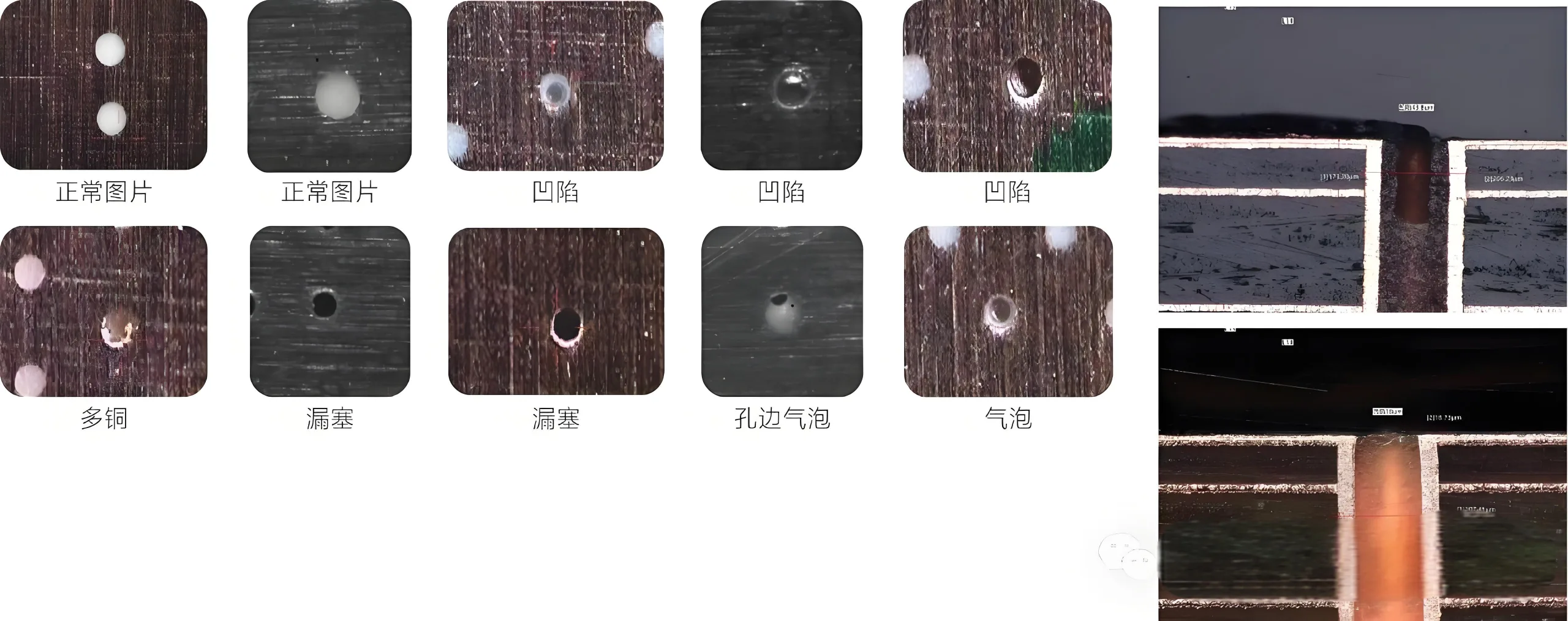

4.Leveling

Since resin slightly protrudes above the board surface after plugging, it’s necessary to grind its surface smooth using abrasive belts or ceramic brushes for subsequent processes to proceed smoothly. During this process, grinding directions should be changed multiple times to avoid uneven copper thickness or excessive cutting of large holes.

Resin Plug for PCB

III. Advantages: Dual Enhancement of Performance and Efficiency

1.Enhancing Product Reliability

PCB resin plugging effectively solves the problem of solder leakage, avoiding contamination hidden by cracks in plugging and the resulting Conductive Anodic Filament (CAF) phenomenon. According to industry data, PCBs using the resin plugging process have seen their reliability increase by more than 30% compared to traditional ink plugging processes, significantly improving product lifespan and stability.

2.Improving Signal Integrity

There’s a close relationship between resin plugging and signal integrity. By optimizing the plugging process, signal transmission paths can be improved, reducing signal loss and interference. This advantage is particularly evident in electronic devices transmitting high-frequency, high-speed signals.

3.Increasing Part Density

The resin plugging process also creates favorable conditions for increasing part density on PCBs. By precisely controlling the filling and sealing of holes, more components can be arranged and interconnected within limited space. As electronic products trend towards lighter, smaller, and more integrated development, the importance of this process becomes increasingly prominent.

4.Looking Forward

A New Chapter for Resin Plugging Technology

Looking ahead, with the continuous growth in demand for high-density, high-difficulty PCB boards, resin plugging technology will play an even more pivotal role in the field of PCB manufacturing. On one hand, with ongoing advancements in materials science, the development of new resin materials will further enhance the performance and reliability of plugging processes. On the other hand, the introduction of intelligent, automated equipment will further improve production efficiency and quality control levels of plugging processes.

Moreover, we should recognize that resin plugging is not an isolated process but closely linked with other aspects of PCB manufacturing, forming a complete chain of electronic product manufacturing. Therefore, in future developments, how to better integrate resin plugging with other processes to optimize overall performance will be an important topic for the industry.

Conclusion: Precision Guardianship, Shaping the Future Together

PCB resin plugging, a seemingly simple process, plays a vital role in electronic manufacturing. It is not only the guardian of circuit board reliability but also a promoter of enhanced electronic product performance. In future developments, we have every reason to believe that with continuous technological progress and sustained innovation, resin plugging technology will shine even brighter in the field of electronic manufacturing, contributing more to human technological advancement.

UGPCB LOGO

UGPCB LOGO