Rogers RO4350B: The Premier Radio Frequency PCB Material

Rogers RO4350B stands as the most popular radio frequency PCB material, renowned for its hydrocarbon/ceramic laminate composition and a dielectric constant of 3.48. This article delves into the key features, technical specifications, advantages, typical applications, and considerations for selecting this versatile PCB material.

Overview of Rogers RO4350B

Rogers RO4350B is a patented hydrocarbon resin system reinforced with ceramic filler and woven glass cloth. Its electrical properties closely resemble those of PTFE/woven glass cloth materials, while its machinability is akin to epoxy resin/glass cloth materials. This unique combination allows Rogers RO4350B to utilize standard epoxy/glass cloth processing technology, offering strictly controlled permittivity and loss at a fraction of the cost of traditional microwave materials. Special through-hole pretreatment or operations typically required for PTFE PCB microwave materials are unnecessary.

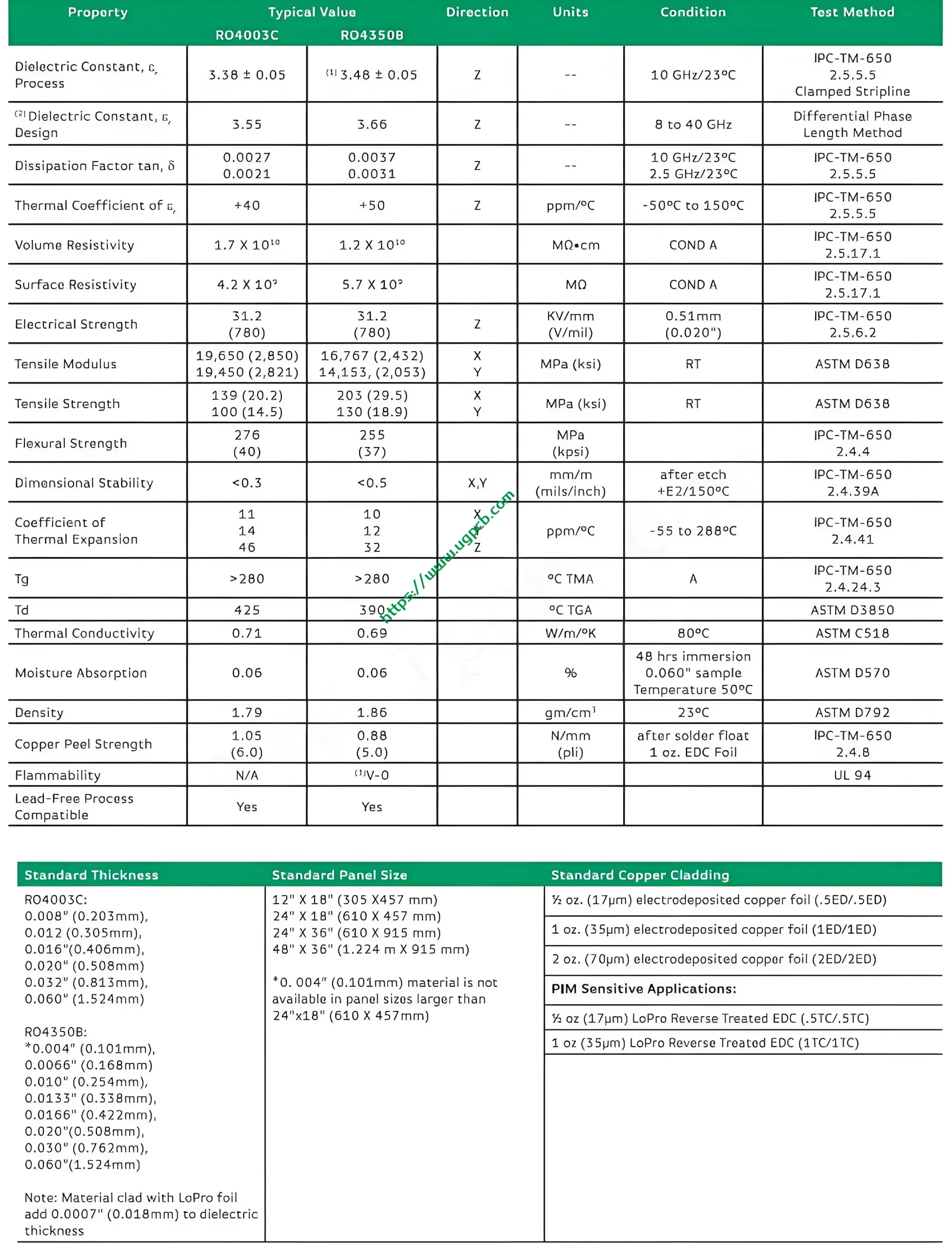

Technical Specifications of Rogers RO4350B

The technical specifications of Rogers RO4350B underscore its suitability for high-frequency applications. Key parameters include:

- Dielectric Constant: 3.48

- Low RF Loss: Ensures efficient signal transmission.

- Low Dielectric Constant Fluctuation with Temperature: Maintains stability across varying temperatures.

- Low Z-Axis Thermal Expansion Coefficient: Minimizes dimensional changes due to thermal variations.

- Coefficient of Expansion in Low Plate: Facilitates reliable performance.

- Low Permittivity Tolerance: Guarantees consistent electrical properties.

- Stable Electrical Characteristics Across Different Frequencies: Supports broadband applications.

- Ease of Mass Production and Multilayer Mixing with FR4: Offers high cost-performance ratio.

Advantages of Rogers RO4350B PCB

Rogers RO4350B PCB boasts several advantages that make it a preferred choice among designers:

- Low RF Loss: Ensures minimal signal degradation.

- Consistent Dielectric Properties: Maintains stable performance over temperature changes.

- Thermal Stability: Low z-axis thermal expansion coefficient enhances reliability.

- Cost-Effectiveness: Achieves an optimal balance between cost and high-frequency performance.

- Compatibility with Standard Processing: Can be processed using standard epoxy/glass cloth techniques.

- Versatility: Suitable for mass production and multilayer designs.

- High-Frequency Performance: Excels in frequencies generally below 30GHz.

Typical Applications of Rogers RO4350B PCB

Due to its exceptional properties, Rogers RO4350B is widely used in various high-frequency applications, including:

- Cellular Base Station Antennas and Power Amplifiers

- Microwave Point-to-Point Connections (P2P)

- Automotive Radar and Sensors

- Radio Frequency Identification (RFID) Tags

- Low Noise Block (LNB) for Live Satellite

Considerations for Selecting PCB Materials

For high-frequency circuit design engineers, the plethora of PCB materials available can make selection challenging. Key factors to consider include:

- Working Frequency: Ensure the PCB material’s frequency range meets the application’s requirements.

- Dielectric Constant and Its Variation: Crucial for maintaining design integrity within the desired bandwidth.

- Line Width Calculation: Different dielectric constants necessitate recalculations or simulations for transmission lines.

Impact of Copper Foil Roughness on Design DK

The design DK of high-frequency PCB materials is influenced by the roughness of the copper foil used. Rougher surfaces increase the effective DK value, which must be accounted for in designs to ensure accurate impedance matching and signal integrity.

Compatibility and Cost-Effectiveness

Rogers RO4350B, with its compatibility with standard processing techniques and low line processing costs, offers a cost-effective solution for high-frequency PCB needs. It achieves an optimal balance between performance and affordability, making it the most cost-effective low-loss high-frequency PCB material available.

In conclusion, Rogers RO4350B emerges as a top choice for radio frequency PCB applications, combining superior electrical properties, ease of processing, and cost-effectiveness. Its wide range of applications and technical advantages make it a staple in the industry for designers seeking reliable high-frequency solutions.

UGPCB LOGO

UGPCB LOGO