Standard PCB Design

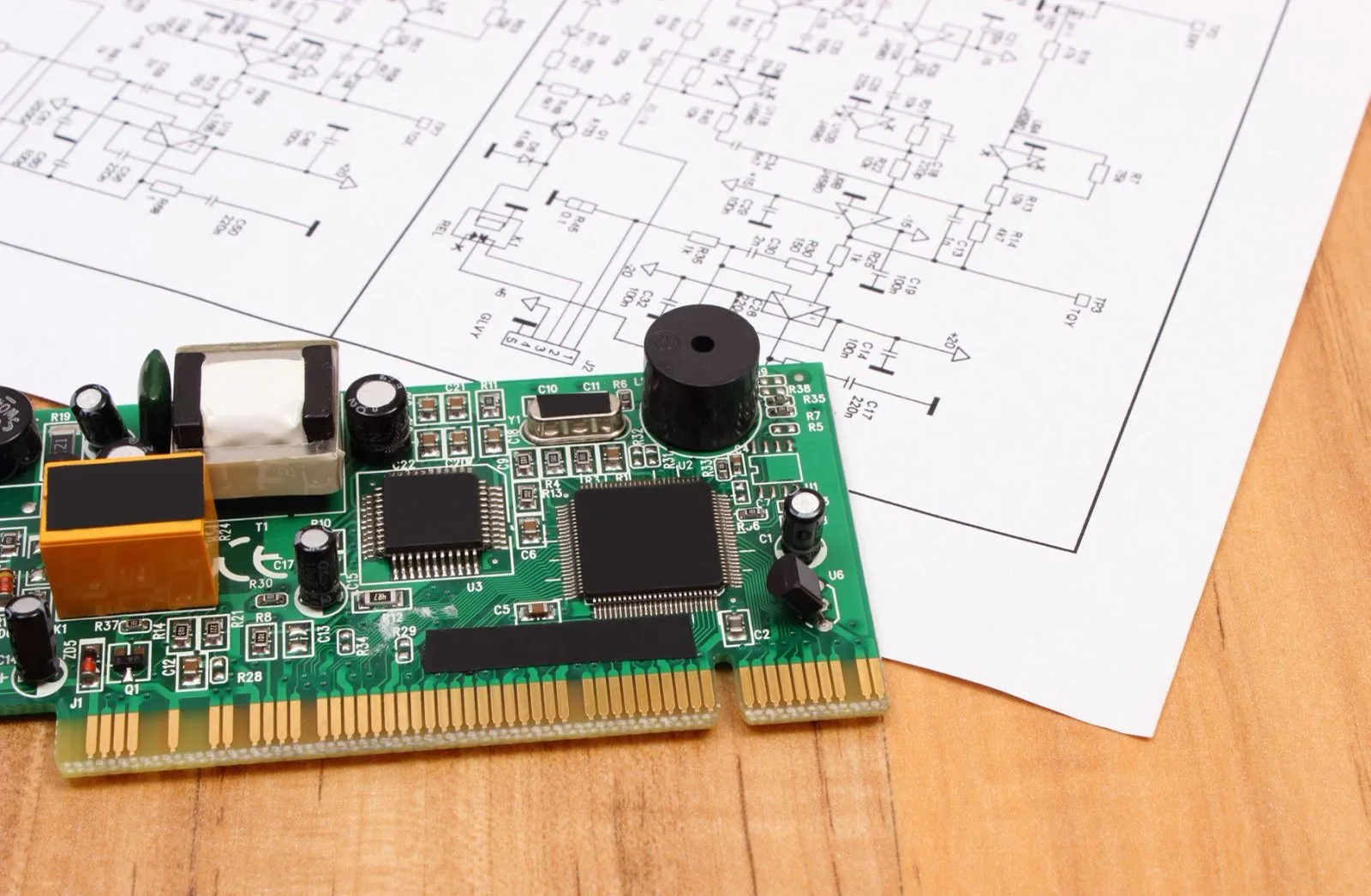

Standard PCB Design: The Industrial Practice of High-Cost Performance and Reliable Interconnection Solutions

In the fields of consumer electronics, industrial control, and Internet of Things (IoT) devices, standard PCB design undertakes the fundamental interconnection needs of over 80% of electronic systems. We focus on the industrial design optimization of conventional 1 – 12 layer PCB boards. Through scientific structural planning, precise process adaptation, and intelligent manufacturing process control, we provide global customers with cost – effective and reliable mass production solutions. We have cumulatively delivered more than 50 million square feet of standard circuit boards.

Core Technical Features

Universal PCB Design Optimization

- Supports conventional PCB materials such as FR – 4, CEM – 1, and aluminum base, with line width/line spacing accuracy reaching ±0.05mm and a minimum hole diameter of 0.3mm, meeting IPC – A – 600 Class 2 standards.

- An intelligent panel nesting algorithm is developed, increasing material utilization to 93% and reducing the overall cost by 15% – 20%.

Mixed Signal Compatible Design

- Adopts power integrity (PI) plane segmentation technology to enable digital/analog circuit co – board design (crosstalk suppression > 25dB).

- Implements dynamic impedance control scheme (tolerance ±10%) suitable for medium – speed signal protocols such as USB 3.0 and CAN bus.

Manufacturability Deep Synergy

- Integrates DFM Checker expert system to automatically identify more than 20 process risk points such as pad pitch/hole diameter ratio.

- Provides Gerber – to – G – code automatic conversion to ensure seamless integration of PCB board design and production data.

Industrial Manufacturing Advantages

Efficient Mass Production Capacity

- Fully automated production line supports a monthly capacity of 300,000㎡, with the fastest delivery time of 24 hours for double – sided PCB board prototyping.

Precision Process Control

- Etching compensation technology with line width tolerance of ±8μm.

- Copper plating thickness of 18 – 25μm (in compliance with IPC – 6012E standard).

- Green oil bridge control ≥0.1mm (to prevent wave soldering short circuit).

Detection System

- 100% implementation of AOI optical detection (minimum defect recognition area of 0.02mm²).

- Sampling for thermal stress testing (solder heat resistance at 288℃/10s).

Industry Application Solutions

Smart Home

- Designs 6 – layer hybrid PCB boards integrated with WiFi/Bluetooth modules, with a mass production yield rate of over 99.2%.

Industrial Controller

- Develops 4 – layer heavy copper boards (3oz) passing 1000 – hour salt spray test (IEC 60068 – 2 – 52).

Automotive Electronics

- Provides 12 – layer through – hole boards with temperature resistance range of – 40℃~125℃, certified by AEC – Q100.

Value Promise of Standardized Service

Cost – Optimal Strategy

- Material library covers more than 30 brands including Shengyi and Taiguang, providing tiered pricing schemes.

Rapid Response System

- Feedback on design consultation within 4 hours.

- Completion of project confirmation for 8 – layer boards within 48 hours.

Quality Assurance

- Implements IPC Class 2/3 standard graded control.

- Provides third – party CNAS inspection reports.

Take action now: Consult our professional PCB design engineer team immediately to get the most cost – effective quote.

Let basic design achieve extraordinary quality – we safeguard the reliable gene of every circuit board with industrial precision.

UGPCB LOGO

UGPCB LOGO

WeChat

Scan the QR Code with WeChat