LED advantages:

- Regional scalability. The LCD area is large, and it is difficult to achieve seamless splicing, but the LED display can be arbitrarily expanded and seamlessly stitched.

- Liquid crystal plasma screens decay rapidly in brightness, requiring a replacement every half a year to a year on average. The LED display can operate without problems for at least five years under the same operating conditions.

- The LED flash machine can utilize interactive technology, enhance interaction with the advertising media as the flash machine, implement customized touch screens such as cloud-based broadcast control, and so on.

- In terms of display effects, the LED display has higher brightness, better color rendition, and good color reproduction capabilities. The refresher generally has super grayscale control up to 4096-4164 levels, with clear and vivid colors displayed. The LED display screen is widely used in airports, malls, hotels, high-speed railways, cinemas, exhibitions, etc., with strong consumer purchasing power and huge advertising value.

The performance of LED display is superior:

(1) Bright light emission intensity, visible when viewing directly within the sun’s surface distance, the display content is clearly visible. Super grayscale control has a color display level of more than 10.7 million M, with clear and vivid colors. Color reproduction ability is very strong.

(2) Static scan technology ensures that the full power of the LED lamp is guaranteed, using a static locking scanning mode to fully ensure the luminous brightness.

(3) Imported large-scale integrated circuits, comprehensive use of imported large-scale integrated circuits to greatly improve reliability, easy maintenance.

(4) Automatic brightness adjustment. It can automatically adjust the brightness according to different brightness environments to obtain the best playback effect.

(5) Advanced digital video processing technology, distributed scanning technology, BSL liquid crystal splice HD display technology, modular design, constant current/constant voltage static drive, automatic brightness adjustment, ultra-pure pixel pure color, bright pixels, no flicker and no ghosting, eliminating distortions and jitter. Video, animation, charts, text, information display, network display, remote display.

The color of LED can be different from the material used to make LED, which can generate photons of different energy, thereby controlling the wavelength of the light, or spectrum.

- The first LED material used was arsenic (As) and gallium (Ga), with a forward voltage drop (VF) of 1.424V to light up green light.

- Another common LED material is phosphorus (GaP), with a forward voltage drop of 2.21V to lightemit green light.

- Based on these two materials, the early LED industry adopted the GaAs1_xPx material structure, theoretically capable of producing red light from infrared to green light. Typically, the LED wavelength and the PN junction pressure drop can determine the LED color. There are red LEDs with a typical GaAs0.6P0.4X of 0.65, yellow LEDs with a GaAs0.35P0.65X of 0.84, and yellow LEDs with a GaAs0.14P0.86X of 0.86. Because of the use of arsenic, gallium, and phosphorus in manufacturing, these LEDs are commonly referred to as tricolor light-emitting tubes. GaN (blue light LED) phosphate glass LEDs, GaAsP green LEDs and GaInN red LEDs are collectively called binary lights. The latest technology is made by mixing AlGaInN, aluminum (Ca), calcium (In), indium (N) and nitrogen elements into four elemental LEDs. This can cover all visible light and some ultraviolet light spectra.

- The measurement unit of light intensity usually includes illumen units (Lux), flux units (Lumen), and luminous intensity (Candela).

1) 1 CD refers to the luminous intensity of an object radiating completely perpendicularly under the ice point of 60 cm squared. (Original diameter = 2.2 cm, mass = 75.7 g, hourly burning rate = 7.78 grams per hour, flame height = 4.5 cm, horizontal direction light intensity = 1 whale oil candle per square meter).

2) 1 Lm refers to the amount of light emitted by a CD candle to a plane 1 cm away from the center, radiating perpendicularly.

- Active light sources generally use the luminous intensity unit CD, with an angle of auxiliary parameter. For example, white LEDs and incrystal projectors use CD candles as the luminance unit, while transmissive or reflective objects use lux units as the exposure unit. However, the three units are numerically equivalent but need to be understood from different angles. For example, Example: If the luminance (brightness) of a projector is 1600 lumens, and the projector’s entire image is projected onto a 60-inch (1 meter) full-screen, the luminance is 1600 Lux; if its exit aperture is 1 cm, assuming its light output is 1 cm squared, and its light exit aperture is 1 cm squared, then the luminance is 160000 Lux.

- In practical use, the calculation of light intensity often uses easier-to-change data or direction parameters. For example, the light intensity of active light sources such as LED displays is generally expressed in CD/m squared as the angle of auxiliary parameter, and the visual angle is equivalent to the surface luminance unit LUX; if each pixel in the display has a consistent luminescence intensity within a certain space, then this value can assume the total light flow of the display. The actual outdoor LED display must have a brightness of at least 4000 CD/m squared to display well under sunlight. For general indoor LEDs, maximum brightness is about 700-2000 CD/m squared. Single LED luminance is given in CD with an angle parameter. LED luminance varies from several mCD to thousands of mCD. A single LED luminance ranges from several mCD to five thousand mCD. When encapsulating LEDs, the shape of the top lens and the distance between the LED and the top lens determine the LED’s view angle and intensity distribution. Generally speaking, the larger the LED’s view angle, the smaller its maximum luminous intensity but the accumulated luminal hemisphere remains constant.

- When multiple LEDs are closely arranged together their spherical light surfaces overlap causing their entire light emission plane to be relatively uniform. To calculate the display’s light intensity during installation one needs to consider the LED’s viewing angle and LED density according to manufacturer-provided maximum point luminance values, multiply this by 30%-90% as an average display luminance value.

- The lifespan of LEDs typically exceeds 100,000 hours but this only accounts as half of since the LED’s brightness decay cycle also matters. Generally, the brightness decay period should be considered. Under normal economic conditions it is advisable to select slower-decaying four-element LEDs. The rated brightness provided by LED manufacturers for LEDs refers to the optimal brightness and viewing angle when driven at 20mA. However, this actually represents only half of the original brightness.

- Although LEDs generally have long lifespans their brightness decay cycles vary significantly depending on the technology used behind their production. Generally speaking, faster-decaying components should be selected for longer lifespan LEDs.

- The spectral composition of LEDs varies with different materials resulting in different wavelengths of light they can produce. For example, there is a certain comparability between red, blue and green light-emitting components but not between green and yellow components due to phosphorescence effects which affect the purity of the mixed white light. Therefore achieving full-spectrum white requires balancing the proportions of the three primary colors through precise control of including deviations in primary color brightness. This process is known as color matching to achieve white light.

- Before blending colors in full-color LEDs it is crucial to choose a ratio of 3:6:1 for red, green and blue LED components to achieve the brightest possible result while maintaining the lowest cost and highest efficiency.

- White balance requires that under the same grayscale value the synthesized colors remain pure white.

- Primary colors refer to colors that can synthesize all other colors. In shadow light the primary colors are red, green and blue with varying proportions synthesizing millions of colors. Deviation in primary colors reduces the color gamut and decreases color saturation and purity.

Future trends:

- LED display stages have developed rapidly forming a new industrial phase with significant development potential. This stage is divided into three main parts:

- a) The utility stage of LED displays featuring environmental protection, high brightness, high definition and high reliability but initially only meeting market demand without achieving quality standards. With advancements in LED display technology products now show significant improvement and progress beyond previous stages. Additionally, a series of products distinct from traditional light source applications have emerged gaining popularity and becoming widespread. LED displays will continue to evolve offering broader spaces and greater development opportunities.

- b) As LED control technology advances and matures, the semiconductor industry will ride this high-speed train fully leveraging its high controllability. From homes to offices, from roadways to tunnels, from cars to pedestrian walks, and from indoors to outdoor intelligent control systems will provide higher levels of service for human beings. The LED display industry will transition from product manufacturing to overall solution provision, providing design services from product to whole system solutions with manufacturers vying for technological advantages and market share.

- c) The acceptance phase of adoption of updated LED displays involves customer adaptation and acceptance processes leading to an understanding and transition period for product features and usage habits. Customers require time to understand and accept LED display products making it necessary for manufacturers to focus on quality and cost advantages to attract customers. In commercial settings where price is secondary to quality customers tend to prioritize quality. Therefore manufacturers are competing for both quality and price advantages aiming to offer energy-efficient long-lasting features at competitive prices.

- LED Display Intelligent Control Phase: As LED display technology continues to advance and develop, the LED industry as a semiconductor sector will also catch this fast train, fully leveraging its high controllability. From homes to office buildings, from roads to tunnels, from cars to pedestrian areas, from indoor to outdoor, intelligently controlled LED display systems will bring higher-level services to humanity. The LED display industry will evolve from manufacturing products to designing them and then providing comprehensive solutions.

- LED Display Replacement Acceptance Phase: Due to the characteristics of LED display products, mainly high light efficiency (low energy consumption) and long lifespan, this stage is the initial phase of LED display development. There seems to be some comparability. Of course, customers have an acceptance process, with a transition and acceptance regarding their usage habits and appearance. Letting customers understand the features of LED display products, choosing one that is energy-efficient and long-lasting, makes it easier for them to accept the relatively higher price, especially in commercial settings. Moreover, now customers prioritize quality over price. Therefore, manufacturers are striving for both quality and price advantages. The display effect requirements for screens are higher. When the refresh rate of the display is insufficient, horizontal scanning lines appear. It’s necessary to improve the scanning output technology of the LED display control system so that the refresh rate of the LED display exceeds the shutter speed of ordinary cameras, eliminating scan lines captured by cameras.

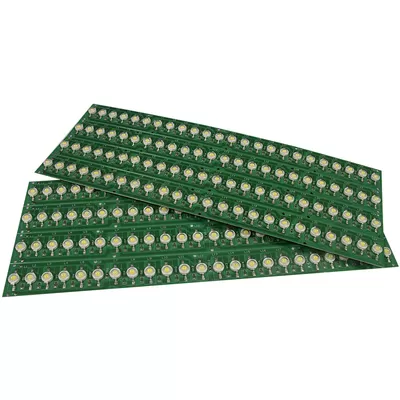

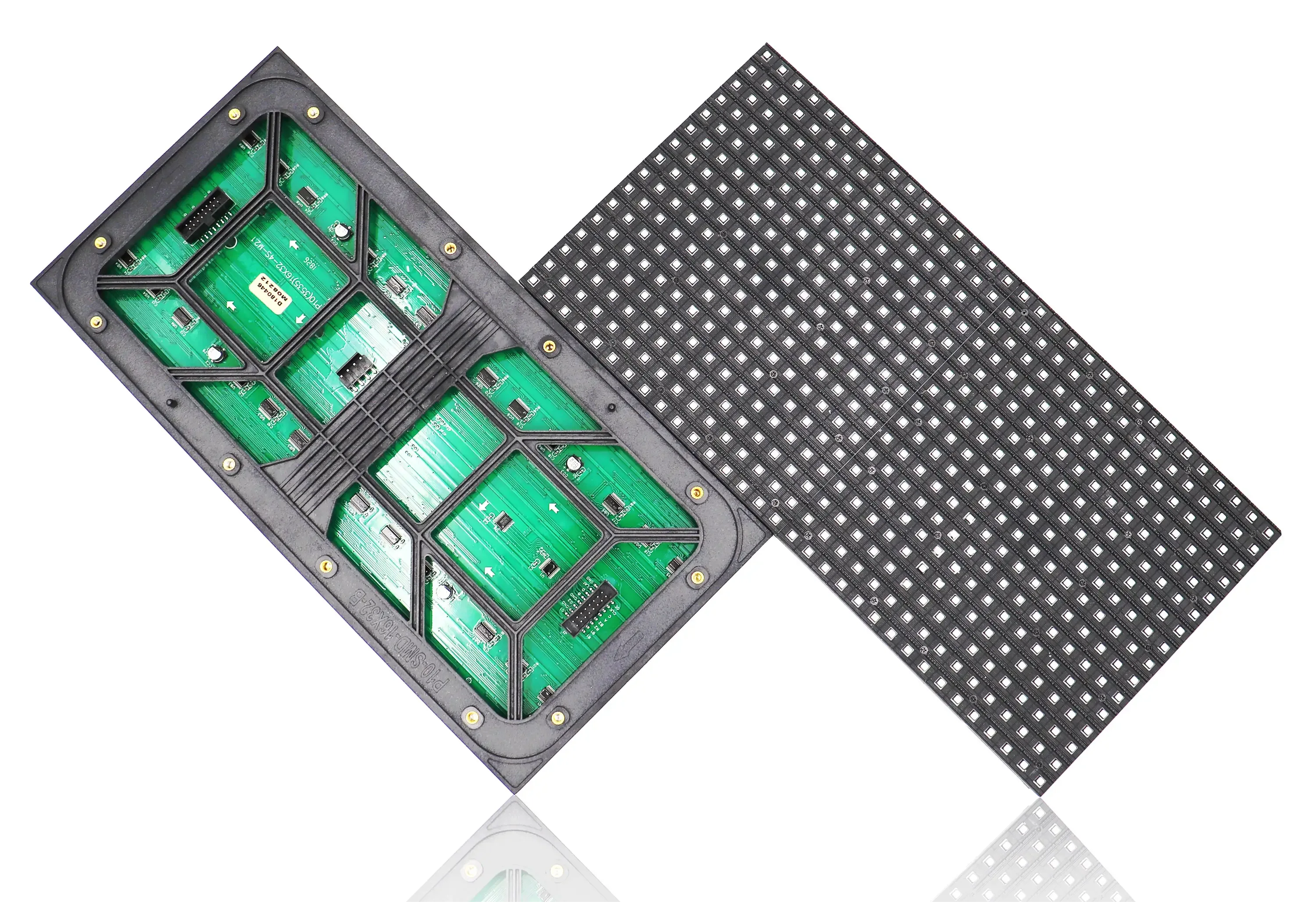

In summary, LED displays are in a phase of rapid growth and development. We believe that in the near future, LED displays will be applied in more fields, and various types of LED displays will emerge on the market. New LED display products will offer consumers better, more convenient, and more energy-efficient options. UGPCB’s AC220V LED panels and PCB components are of excellent quality and cost-effectiveness, making them a qualified supplier.

UGPCB LOGO

UGPCB LOGO