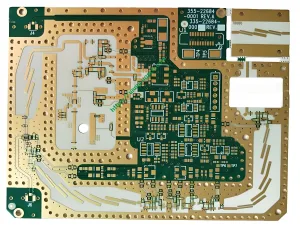

Material Composition

The Antenna PCB RO4350B High Frequency 4 Layer ENIG Board is crafted using a unique blend of Rogers RO4350B and FR4 materials. Rogers RO4350B, a ceramic-filled polytetrafluoroethylene (PTFE) composite, is renowned for its low loss tangent and stable dielectric constant, making it ideal for high-frequency applications. Mixed with FR4, a standard flame-retardant epoxy glass-cloth laminate, it provides both mechanical strength and cost-effectiveness.

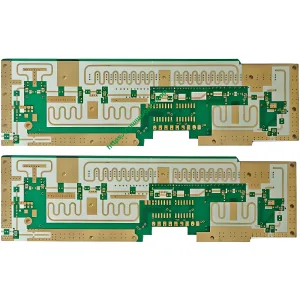

Performance Characteristics

- Dielectric Constant (Dk): 3.48, ensuring consistent signal propagation and minimal signal loss across a wide frequency range.

- Finished Thickness: 1.0MM, offering a compact design suitable for space-constrained applications.

- Copper Thickness: 1OZ, ensuring excellent conductivity and durability.

- Dielectric Thickness: 0.762mm, optimized for impedance control and signal integrity.

- Thermal Conductivity: 0.69w/m.k, allowing for efficient heat dissipation, crucial in high-power radio frequency (RF) circuits.

- Flammability Rating: V-0, ensuring safety compliance in various electronic devices.

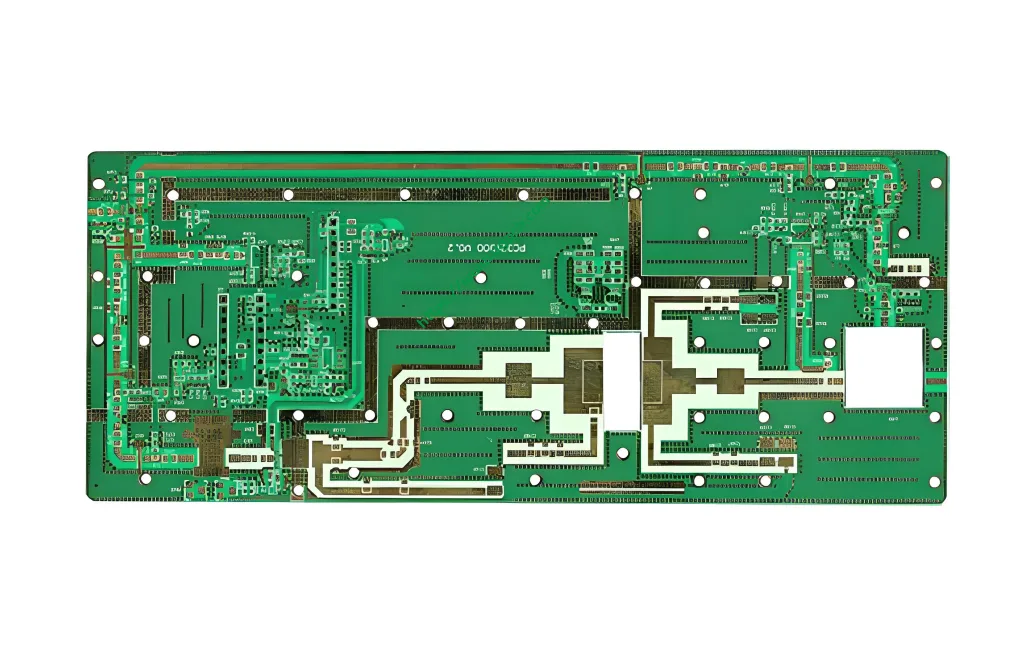

Production Process

The production of the Antenna PCB RO4350B involves several meticulous steps:

- Material Preparation: Rogers RO4350B and FR4 materials are precisely cut and prepared for lamination.

- Lamination: The materials are pressed together under controlled conditions to ensure uniform bonding.

- Circuit Patterning: Using advanced photolithography, the copper circuits are etched onto the laminated board.

- Plating: An immersion gold (ENIG) surface treatment is applied to provide a protective layer that enhances electrical contact and corrosion resistance.

- Quality Control: Each board undergoes rigorous testing to ensure dimensional accuracy, electrical performance, and surface finish quality.

Application Scenarios

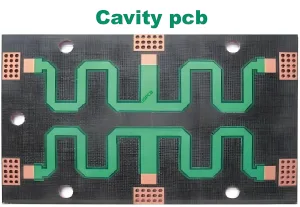

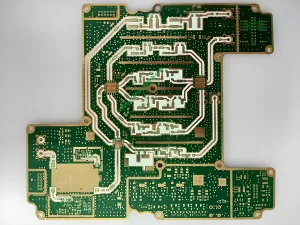

High-Frequency Radio Applications

The Antenna PCB RO4350B is specifically tailored for radio frequency (RF) and microwave antenna applications. Its low loss tangent and stable dielectric properties make it ideal for use in high-frequency circuits where signal integrity and performance are paramount.

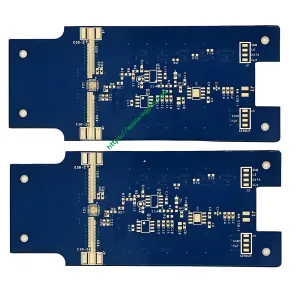

Compact Electronic Devices

Due to its compact 1.0MM thickness and excellent thermal conductivity, this PCB is well-suited for use in space-constrained electronic devices, such as smartphones, tablets, and wearable technology, where both size and thermal management are critical factors.

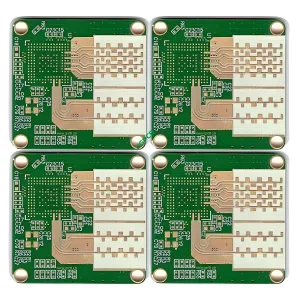

Antenna Arrays and Systems

In antenna arrays and complex RF systems, the consistent dielectric constant and impedance control of the RO4350B material contribute to enhanced signal reception and transmission, making it an excellent choice for telecommunications, radar, and satellite communication systems.

Conclusion

The Antenna PCB RO4350B High Frequency 4 Layer ENIG Board combines the superior electrical properties of Rogers RO4350B with the cost-effectiveness and mechanical strength of FR4, making it a versatile solution for high-performance RF and microwave antenna applications. Its meticulous production process ensures reliability and quality, while its compact design and excellent thermal conductivity cater to the demands of modern electronic devices.

UGPCB LOGO

UGPCB LOGO