Industrial Control Motherboards

Industrial control motherboards are motherboards used in industrial occasions and are utilized by industrial computers. They can adapt to wide temperature environments, harsh environments, and long-term high-load work.

1. What is an Industrial Control Motherboard? (Meaning of Industrial Control Motherboard)

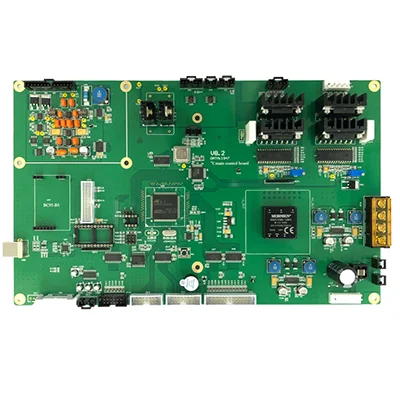

The industrial control motherboard is a special motherboard mainly used for industrial computers to assist in dealing with industrial projects. The industrial control motherboard is a card-shaped composite board. Like commercial motherboards, it is filled with various industrial components and covered with various sockets. From the board type, the industrial control motherboard is relatively small, and there are two, three, or four PCL ports! There will also be two or more memory sockets, and the industrial control motherboard uses low-power chips to address issues such as energy consumption and high temperature during long-term operation. It is resistant to moisture and high temperatures, has strong adaptability to the environment, so when using it, one must distinguish between commercial motherboards and industrial control motherboards!

2. The Characteristics of Industrial Control Motherboard!

Industrial control motherboards are primarily suitable for design, industrial, and other project applications. Therefore, most of the machines used in engineering projects utilize industrial control motherboards. Using industrial control motherboards can improve efficiency, reduce labor maintenance times and costs, as well as their overall usage costs. In terms of design, materials, and other aspects, industrial control motherboards exhibit exceptional performance, with corresponding stability, a relatively low accident rate, high relative stability, a low failure report rate, and robust third-party functionalities. Additionally, the industrial control motherboard is suitable for operation between -40 degrees and 90 degrees Celsius. The temperature range and humidity ratio can also be between 0 and 95%. It also possesses strong self-radiation control, making it very suitable for environments with metal dust or ordinary dust!

3. The Main Function of Industrial Control Motherboard

The industrial control motherboard is primarily suitable for industrial control equipment, GPS navigation, and the production of other precision data! Some units require a stable system background, and the industrial control motherboard can fulfill this role, helping individuals reduce costs. The benefits of science and technology have increased, profitability has risen, and labor costs have also been reduced. However, the relative price is also comparatively high, and the application range of industrial control motherboards is expanding! Concurrently, economic status is gradually improving!

Basic Content

The industrial control motherboard is a motherboard used in industrial settings. It is adopted by industrial computers and can adapt to a wide range of temperatures, harsh environments, and sustained high-load operation.

The So-Called Industrial Control Motherboard

- CPU can be a common plug-in type, and some are board-mounted.

- Memory slot is usually 1-2.

- Integrated Graphics.

- There are numerous I/O devices, but some motherboards may omit the printing port.

- PCI slot is typically around 2-3.

- Plate type is relatively small.

The motherboard that truly meets the industrial control standard is divided into two parts!

The first part is the “Industrial Control Motherboard” section! The function of this part is the same as the motherboard we commonly use! However, the industrial control motherboard is designed as a card! It resembles a giant graphics card! There are two rows of gold fingers on the bottom of the motherboard! However, this section does not include any expansion slots!

The second part is the “Expansion Interface Board” section! It features several PCI and ISA slots! There is also a slot for connecting the “industrial control motherboard”!

During actual installation, the “expansion interface board” is fixed to the chassis’ bottom plate! And the “industrial control motherboard” is plugged into the “expansion interface board”! It may sound unusual…but this structure facilitates the addition of multiple PCI or ISA devices.

Structure: Embedded PC/104 Industrial Motherboard

- Processor: On-board NS GEODE GX1 CPU, main frequency 200/233/266/300/333MHz optional.

- Chipset: NS GEODE CS5530A.

- System Memory: A notebook memory interface (144 PIN SO-DIMM).

- BIOS: Award BIOS, plug and play.

- Display Interface: Supports CRT, 18bit TFT LCD, 4M shared memory. Maximum VGA resolution is 1024×768×24bpp﹑1280×1024×8bpp; LCD TFT maximum support 1024×768×18bpp.

- Enhanced IDE: Supports standard hard disk and CD-ROM, can carry CF adapter card.

- Super I/O: Winbond W83977 chip, two serial ports, one parallel port, one keyboard/mouse interface, no floppy drive interface.

- Watchdog Circuit: 16-level watchdog timer function, 1-second time interval, time can be set to 0-15 seconds.

- Network: Realtek 8139DL 10M/100M network card.

- USB: 2-way USB1.1 interface.

- Power Supply: +5V@1.4A (maximum), single power +5V power supply.

- Dimensions: 90.2mm×95.9mm.

- PCB Board Layers: 8 layers, strong anti-electromagnetic interference ability.

- Working Environment: Temperature 0°C to 60°C, relative humidity 5% to 95%, non-condensing.

- Anti-EMI Design: Serial port, parallel port, CRT interface, keyboard/mouse interface anti-EMI design.

- Serial Port Features: COM2 can be configured as RS232/RS485 without jumpers, and COM1 is standard RS232.

Featured Recommendation: High-performance, PC/104 size Pentium MMX-class motherboard, with network card, USB.

Main Applications

Industrial control equipment, GPS navigation, sewage online monitoring, air online monitoring, instrumentation, professional equipment controllers, military industry, government agencies, telecommunications, banks, electric power, car LCD, monitor, video doorbell, portable DVD, LCD TV, environmental protection equipment, etc.

Characteristic

- Working Temperature and Heat Dissipation: Industrial control motherboards can operate stably and without failure between -20°C and 60°C, and even some industrial control motherboards adopt special wide temperature design, with a temperature range reaching -20°C to 70°C. This poses a severe test for the organization’s heat dissipation scheme and efficiency. In the heat dissipation design of the industrial control motherboard mechanism, an all-aluminum mechanism shell and a special heat dissipation design must be used, along with special treatment for large heat-generating units such as the CPU, north and south bridges, and hard drives to ensure the normal operation of the industrial control motherboard and the entire system.

- Management: In addition to providing similar remote connection management, the industrial control motherboard can also achieve remote unattended automatic power on and off. Through the embedded IPMB and SMNP-1000 modules, the management, recording, and transmission of real-time system operation information can be realized.

- Protection Function: The industrial control motherboard is specially designed to realize functions such as watchdog automatic restart and anti-surge impact in case of abnormalities like crashes, fully ensuring the high stability of the system in harsh environments.

- Market Size: Industrial control motherboards are primarily customized products, with relatively small output and market size, and the cost of switching to other brands of motherboards is high. Therefore, users who choose industrial control motherboards generally do not easily switch to other brands.

We provide Industrial Control Turnkey PCB Assembly, Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly factory.

UGPCB LOGO

UGPCB LOGO