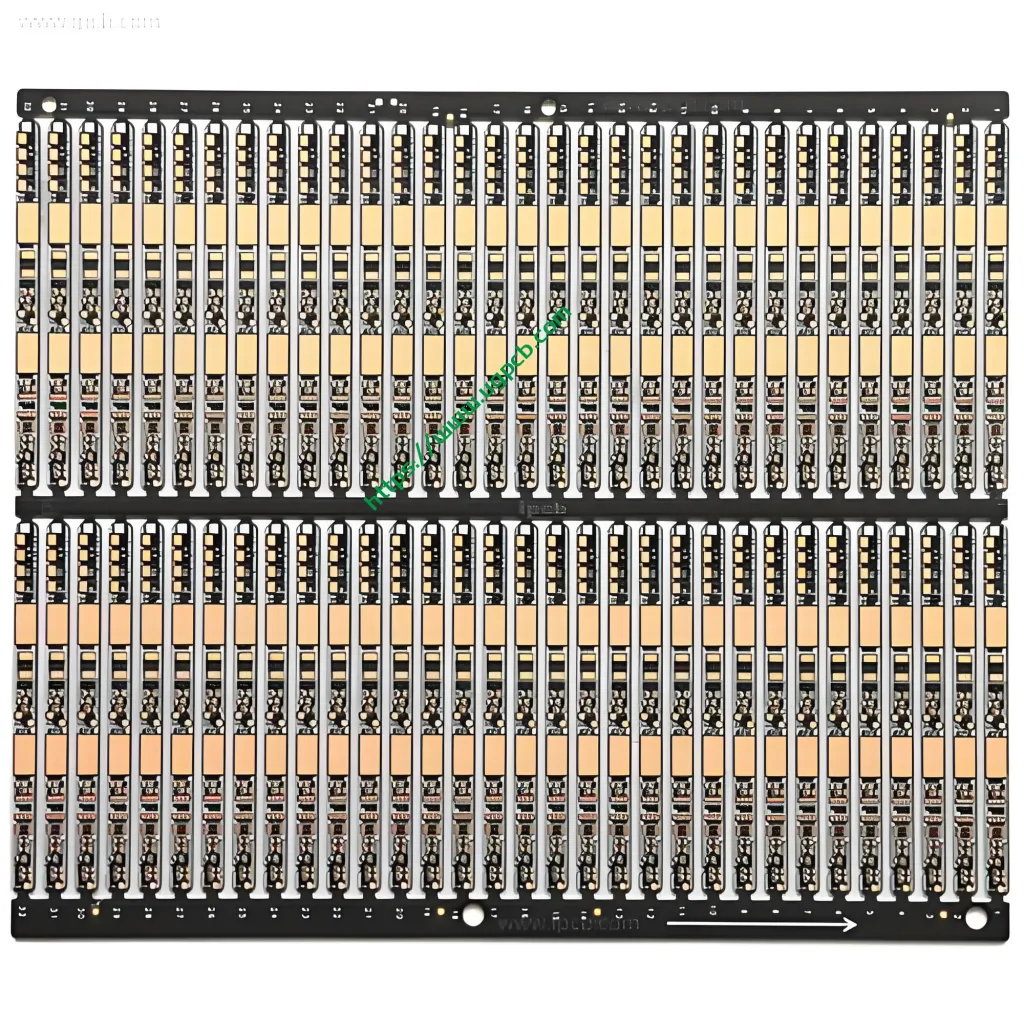

Introduction to Battery Protection PCB Board

Battery protection PCB board, as the name implies, is primarily designed for rechargeable batteries (typically lithium batteries) to safeguard the integrated PCB board. The necessity for protecting lithium batteries (rechargeable type) stems from their inherent characteristics. Due to the material composition of lithium batteries, they cannot endure overcharging, over-discharging, overcurrent, short circuits, or ultra-high temperature charging and discharging. Consequently, lithium battery components are invariably accompanied by a protective PCB equipped with a sampling resistor and a current protector.

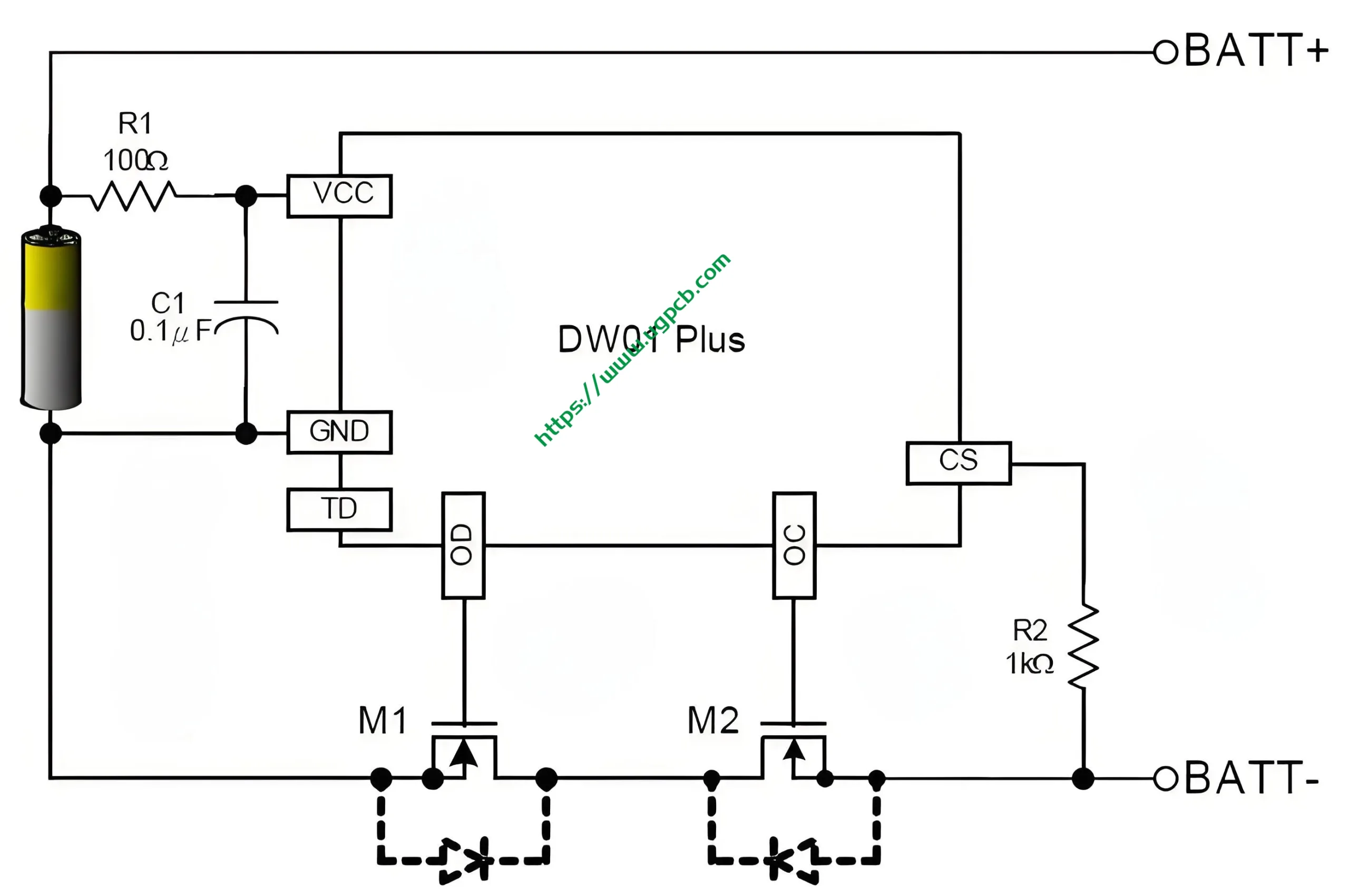

Battery Protection Circuit

Main Functions of Battery Protection PCB Board

-

Overcharge Protection

Charging directly on the mobile phone using the original direct charging device will automatically activate the protection circuit of the battery protection board. -

Discharge Protection

Instantaneously short-circuit the positive and negative electrodes of the battery. Observe the spark on the electrode piece. Repeat this process a few times before proceeding with direct charging. -

Over-current and Short-circuit Protection

Utilize a 5V DC source, touch the positive and negative electrodes of the battery with the corresponding electrodes, repeat the process several times, and then charge the battery with the original charger.

UGPCB LOGO

UGPCB LOGO