Material

Advanced Composite Material

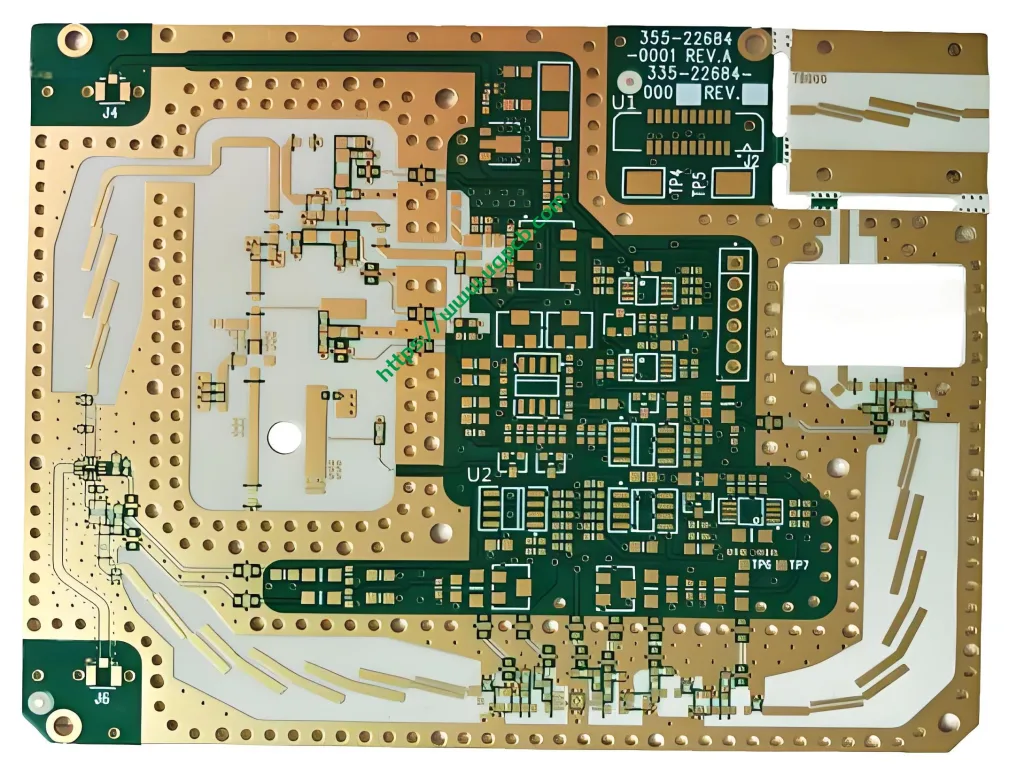

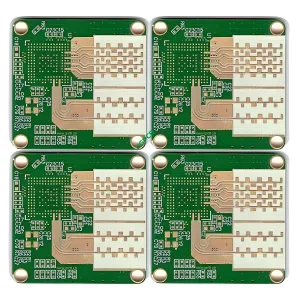

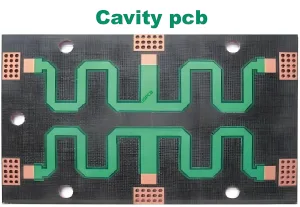

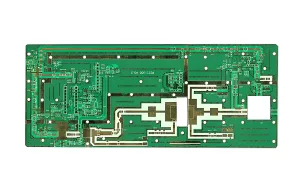

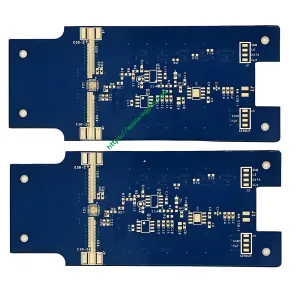

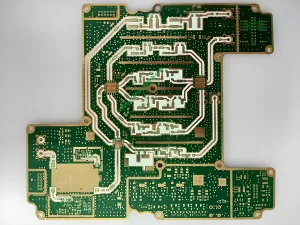

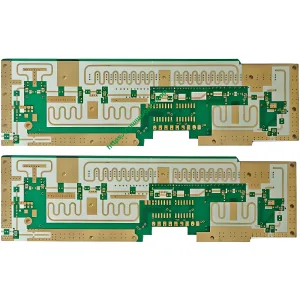

The RO4350B + IT180 Mix Laminate High Frequency PCB Board is made from a mix of Rogers RO4350B and IT180. Rogers RO4350B is a high-performance microwave/RF laminate known for its low loss, high stability, and excellent processability. IT180 is a reinforced glass fiber material that provides additional mechanical strength and thermal stability. This mixed material enables the PCB board to exhibit excellent performance and reliability in high-frequency applications.

Performance

Outstanding Electrical Performance

- Dielectric Constant (DK): 3.48

- A stable dielectric constant helps reduce signal loss and delay, ensuring the quality of high-frequency signal transmission.

- Impedance Control: 50 Ohms

- A standard impedance value ensures matched and stable signal transmission, reducing reflections and interference.

- Dielectric Thickness: 0.508 mm

- An appropriate dielectric thickness further enhances the high-frequency signal transmission performance.

Excellent Thermal Management

- Thermal Conductivity: 0.69w/m.k

- High thermal conductivity material aids in heat dissipation, protecting circuits from overheating damage and ensuring stability in high-power applications.

Advanced Production Process

- Number of Layers: 6 Layers

- A six-layer design accommodates complex circuit layouts and wiring requirements.

- Blind Hole: 1L~2L HDI

- High-Density Interconnect (HDI) blind hole technology enables a more compact circuit layout and higher signal transmission efficiency.

- Copper Thickness: 1 Ounce

- Adequate copper thickness provides good current carrying capacity and signal transmission performance.

- Surface Treatment: Immersion Gold

- Immersion gold surface treatment offers excellent electrical conductivity and corrosion resistance, enhancing circuit reliability and stability.

Production Process

Raw Material Preparation

- Prepare Rogers RO4350B and IT180 mixed materials, as well as auxiliary materials such as copper foil and solder mask ink.

h3: Laminating and Pressing

- Laminate and press the mixed materials according to the designed number of layers to form a multilayer board structure.

Drilling and Plating

- Drill holes using laser or mechanical methods to create the required circuit channels.

- Plate the drilled holes with copper to enhance the reliability of circuit connections.

Circuit Patterning and Solder Masking

- Create circuit patterns on the multilayer board and apply a solder mask to protect the circuits from external environmental factors.

Surface Treatment and Testing

- Apply immersion gold surface treatment to improve the electrical conductivity and corrosion resistance of the circuits.

- Conduct rigorous electrical performance and reliability testing on the finished products to ensure quality.

Application Scenarios

Wireless Communication Devices

- Suitable for various wireless communication devices, such as mobile phones, base stations, and routers, providing stable high-frequency signal transmission.

Radar Systems

- In radar systems, the RO4350B + IT180 Mix Laminate PCB can withstand high power and high-speed signals, ensuring the accuracy and reliability of the radar system.

High-Speed Data Transmission Equipment

- Suitable for high-speed data transmission equipment, such as data center switches and storage devices, providing high-speed and stable signal transmission channels.

UGPCB LOGO

UGPCB LOGO