RO3003 PCB Material Characteristics

Low Dielectric Loss

The dielectric loss of UGPCB RO3003 is very low. Even if the working frequency reaches 10 GHz, the dielectric loss factor is only 0.0013. Moreover, RO3003 also has excellent electrical and mechanical properties. At the same time, the laminate has high cost performance, mainly for commercial microwave and RF applications.

Composition and Durability

ROGERS RO3003 PCB is made of PTFE Composites Based on ceramic filling. The melting point is as high as 327 degrees Celsius. It has strong acid-base resistance and high-temperature resistance, which ensures the normal operation of the circuit in harsh environments. Therefore, it can be used as an ideal circuit material for special applications.

Thermal Expansion and Stability

In addition, the thermal expansion coefficient (CTE) of RO3003 in X and Y directions is 17 ppm / degree Celsius, which is equivalent to that of copper. The shrinkage of one inch material after etching and baking is less than 0.5 mil. The thermal expansion coefficient in the Z direction is 24 ppm / degree Celsius, which can ensure the stability of electroplated through-holes even in severe thermal environments.

Stable Dielectric Constant

Because the step phenomenon of the dielectric constant of PTFE glass cloth material near room temperature is eliminated, the change of the dielectric constant of RO3003 with temperature is very stable. Regardless of the dielectric constant, Rogers RO3003 PCB material has stable mechanical properties, which ensures that designers will not encounter warpage or reliability problems when developing multilayer boards.

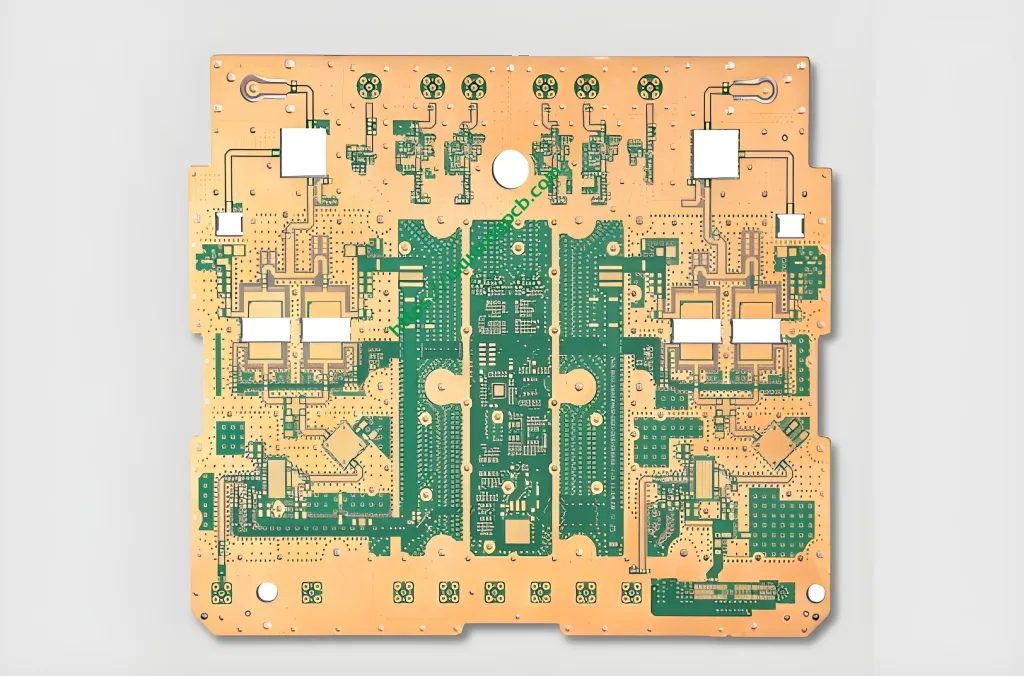

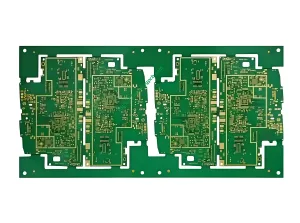

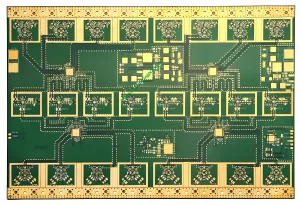

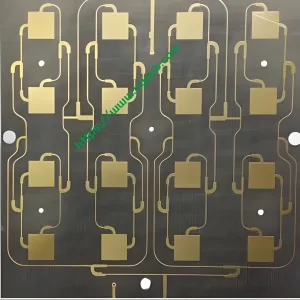

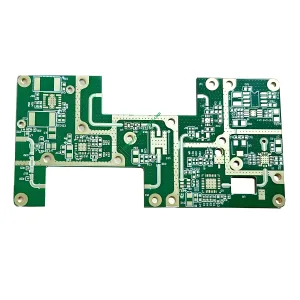

Applications of RO3003 PCB Material

Rogers RO3003 PCB material can be processed by standard PTFE PCB technology. Its typical applications are: automotive radar, GPS antenna, power amplifier and antenna in cellular communication systems, patch antennas in wireless communication, live satellites, remote meter reading, power backplanes, and data links of wired systems.

Product Features

- The dielectric loss factor is only 0.0013.

- It can be used in 77 GHz high-frequency circuits.

- Excellent mechanical stability with temperature change.

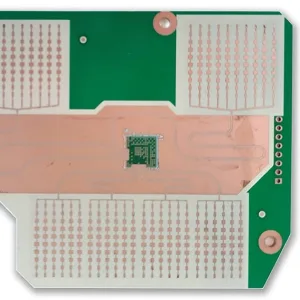

- It can be used in high-reliability stripline and multilayer circuit structures.

- It has the same mechanical stability under different dielectric constants.

- Ideal material for multilayer circuit board design.

- Suitable for mixed design with epoxy glass multilayer circuit boards.

- It has a stable dielectric constant with temperature and frequency.

- It can be used in ideal bandpass filters, microstrip patch antennas, and voltage-controlled oscillators.

- The coefficient of thermal expansion is equivalent to that of copper.

- More reliable SMT process.

- Suitable for temperature-sensitive applications.

- Batch processing, economical plate.

For more technical information about RO3003, please visit: Rogers RO3003 Technical Specifications

RO4835 PCB Material Overview

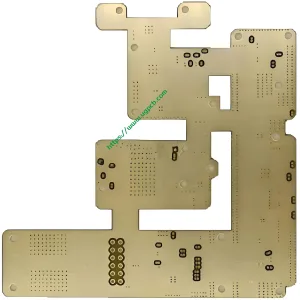

Rogers RO4835 is a kind of high-frequency circuit board material filled with hydrocarbon resin and ceramics, which belongs to civil products. It has the ability to be compatible with FR4 mixed pressure, FR-4 processing technology, and lead-free welding processes.

Dielectric Constant and Thermal Conductivity

At 10 GHz, the dielectric constant in the Z direction (thickness direction) of Rogers RO4835 is 3.48, and the tolerance is ±0.05. The thermal conductivity of the material is 0.69 w/M/°K, and it has very good dimensional stability in the X-Y plane.

Oxidation and Dielectric Properties

With the change of time and temperature, the oxidation will affect all thermosetting boards, and the dielectric constant and loss factor of PCB will increase slightly. The higher the working temperature of the product is, the faster the dielectric constant and loss factor of the PCB board will increase due to oxidation.

Comparison with RO4350B

The materials, electrical, and mechanical properties of Rogers RO4835 are almost the same as those of RO4350B. The biggest difference between Rogers RO4350B high-frequency circuit board material and RO4835 high-frequency circuit board material is that the antioxidant is added to RO4835. Compared with traditional thermosetting materials, the oxidation resistance is increased by 10 times, and it meets the requirements of IPC-4103 (high speed and high-frequency substrate specification). In addition, the dimensional stability, hardness, and water absorption of RO4835 are better than those of RO4350B. However, the temperature characteristic of the DK of RO4835 is relatively poor, which requires a high temperature range of the product, especially the thermal expansion coefficient of the Z-axis becomes worse, and the phase characteristic of high frequency is relatively poor. It is better to avoid using the product with strict requirements on phase.

For more technical information about Rogers RO4835, please visit: Rogers RO3003 Technical Specifications

UGPCB LOGO

UGPCB LOGO