Chip packaging.

On the micro stage of the electronic world, SoC (System on a Chip) and SiP (System in Package) are like two highly skilled artisans, each shaping the future of technology in their unique ways. Though both are leaders in integration technology, they each have their own strengths, making it difficult to determine which is superior. Hoje, let us join the experts from the R&D department of UGPCB to unveil the mysterious veil of SoC and SiP, exploring their subtle differences and respective advantages.

Ⅰ.Definition and Construction: The Art of Microcosm

SoC: Monolithic Integration, Comprehensive Functionality

SOC chip packaging technology.

The term SoC, which exudes a sense of technological sophistication, refers to the integration of all functions such as the Central Processing Unit (CPU), input/output ports (I/O), internal memory, power management circuits, etc., onto a single small chip, much like a puzzle. Imagine a complete computer system compressed into a chip the size of a fingernail—this is undoubtedly a miracle of semiconductor technology.

SiP: Diverse Packaging, Flexible Combination

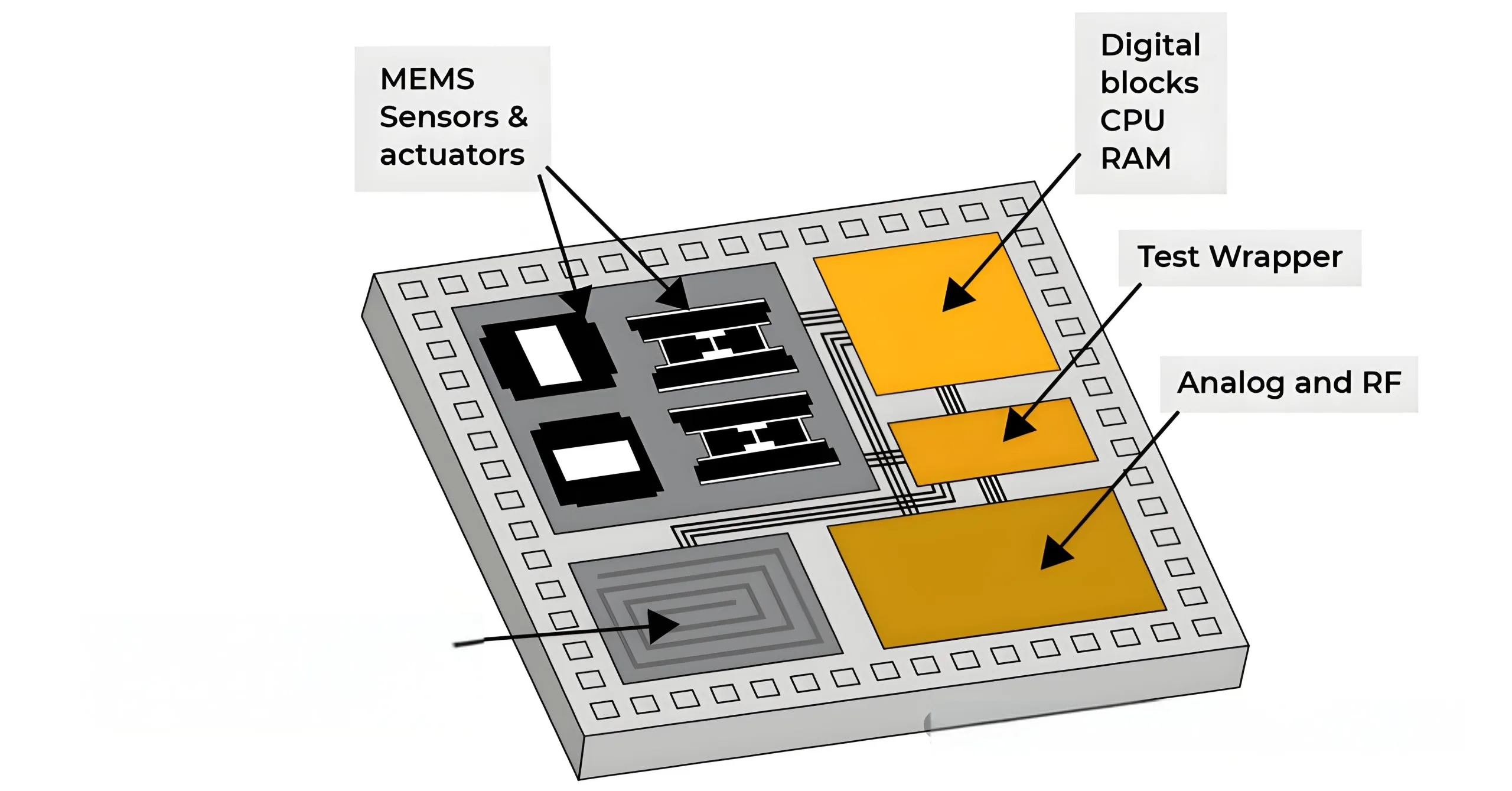

SIP chip packaging technology

Em contraste, SiP adopts a completely different strategy. It does not aim to integrate all functions into a single chip but instead packages multiple different types of chips (such as processors, memories, sensores, etc.) along with passive components (such as capacitors, inductors) onto a PCB substrate, forming a highly integrated system-level package. Esse “modular” approach allows SiP greater flexibility in design.

Ⅱ.Process and Design: A Battle of Precision

Manufacturing Process: Different Roots, Common Goals

The manufacturing process of SoC is a paragon of precision art. All functional modules must be manufactured simultaneously on the same wafer, requiring extremely high process control capabilities and equipment precision. Every step of semiconductor processes such as lithography, gravura, deposition, and CMP (Chemical Mechanical Polishing) must be executed flawlessly, with line widths reaching nanometer scales (such as 5nm, 7nm). This poses ultimate challenges to materials science, physics, and even chemistry.

SiP manufacturing appears more flexible. Each chip can be manufactured independently without being constrained by the same process flow, significantly shortening the design cycle and lowering technical barriers. SiP’s packaging process relies mainly on advanced packaging technologies such as Flip Chip and Bump connections, ensuring reliable interconnection and efficient communication between different chips.

Design Complexity: A Dialogue Between Nanometers and Microns

The design complexity of SoC is astonishing. Designers need to coordinate multiple functional modules at the nanometer scale to ensure good integration under the same process flow, which tests the designer’s wisdom and places high demands on EDA (Electronic Design Automation) tools. Em contraste, SiP design is relatively simpler, with lower precision requirements typically at the micron level, making the design cycle shorter and facilitating rapid iterations and optimizations.

Ⅲ.Space Volume: Compact vs. Spacious

In terms of space occupation, SoC holds an absolute advantage due to its highly integrated nature. No entanto, as functionalities increase, the size of SoC also gradually expands. Mesmo assim, it remains more compact than SiP. SiP occupies relatively more space due to containing multiple independent chips and packaging materials.

Cost: Expensive vs. Economical Choice

While SoC’s high level of integration brings a leap in performance, it also comes with a steep increase in cost. Advanced semiconductor manufacturing processes, complex design procedures, and high R&D investments keep SoC costs high. In comparison, SiP offers more flexible cost control by choosing different levels of chips and packaging materials, effectively reducing costs while meeting performance needs.

Flexibility: A Paradise for Innovation and Customization

The greatest charm of SiP lies in its high degree of flexibility. Designers can freely combine different types of chips and passive components according to needs, and even replace or upgrade existing components, offering infinite possibilities for product innovation. Once an SoC design is completed, its functional modules are difficult to modify, which somewhat limits its ability to adapt to market changes.

Conclusão: Twin Stars Shine, Leading Their Own Realms

As two major branches of semiconductor technology development, SoC and SiP each have their unique charm and application value. SoC, with its high degree of integration and exceptional performance, has become the preferred choice in fields such as smartphones and high-performance computing; whereas SiP, with its flexible design, lower cost, and rapid iteration capability, shines brightly in diverse markets such as IoT and automotive electronics.

In this contest of chip packaging art, there is no absolute winner, only continuously evolving technology and increasingly rich application scenarios. Like twin stars in the night sky, SoC and SiP illuminate the path of technological advancement in their own ways, leading us towards a smarter, better future.

LOGOTIPO UGPCB

LOGOTIPO UGPCB