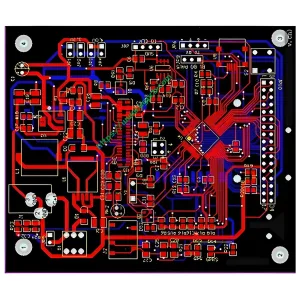

Projeto de PCB HDI

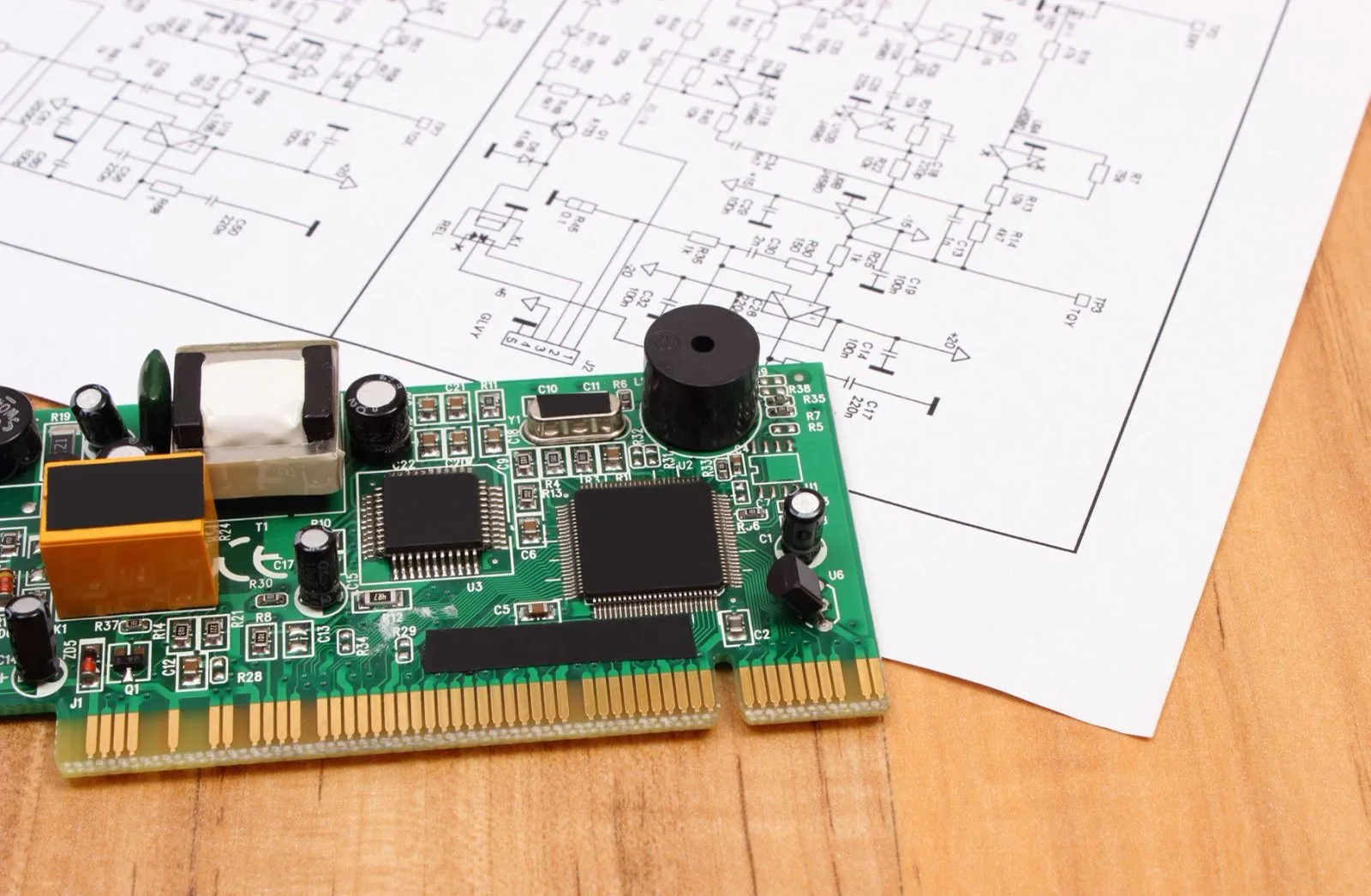

High-Speed HDI PCB Design | The Core Engine Empowering Future Electronic Systems

In the high-speed digital era, IDH (High-Density Interconnect) PCB design has become a core technology supporting cutting-edge fields such as 5G communication, AI computing power, e eletrônica automotiva. As an industry-leading provider of PCB solutions, we specialize in the development and innovative application of cutting-edge technologies for high-speed HDI design, offering global customers high-performance and highly reliable circuit board products through precision craftsmanship and scientific design.

Core Technological Advantages

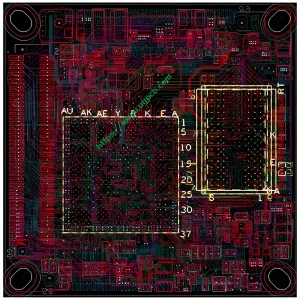

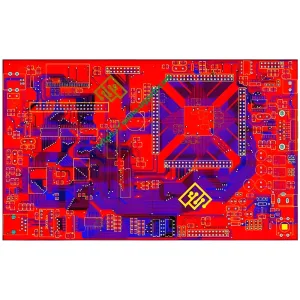

High-Density Interconnect and Signal Integrity Optimization

- Micro-Via and Buried Via Technologies: Utilizing micro-via (<0.15milímetros) and buried via technologies to achieve short-path interconnect between layers, reducing signal transmission delay (typical value ≤0.5ps/mm) and loss by 16%.

- Advanced Impedance Control: Ensuring high-speed signal integrity (por exemplo, PCIe 5.0, 112Gbps SerDes) through advanced impedance control technology (tolerance ±7%) and differential pair routing optimization, reducing crosstalk and reflection issues by 25%.

- Ultra-Fine Line Design: Supporting ultra-fine line design (line width/spacing ≤50μm) and integrating BGA, CSP, and other micro-packages to meet the needs of high-density chip layouts by 37%.

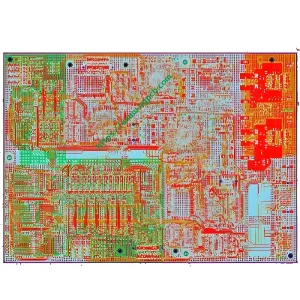

Thermal Management and Material Innovation

- Low Dielectric Loss Materials: Selecting low dielectric loss materials (por exemplo, Rogers RO4000 series, PTFE substrates) with a dielectric constant (Dk) as low as 2.2 and a loss factor (Df) ≤0.0015, suitable for millimeter-wave frequency band (>30GHz) applications by 19%.

- Condutividade térmica aprimorada: Enhancing thermal conductivity by 30% through multi-layer laminated structures combined with embedded heat dissipation channel designs, effectively addressing the heat dissipation challenges of high-power density devices by 56%.

Advanced Manufacturing Process Assurance

- Laser Drilling Precision: Achieving laser drilling precision of ±10μm, combined with via-fill plating technology (via copper thickness ≥20μm), ensuring the reliability of micro-via conductivity by 69%.

- Automated Inspection: Adopting automated optical inspection (AOI) and 3D X-ray inspection to control the defect rate within five parts per million (5 PPM) by 7%.

Addressing Industry Pain Points

Signal Attenuation and Crosstalk

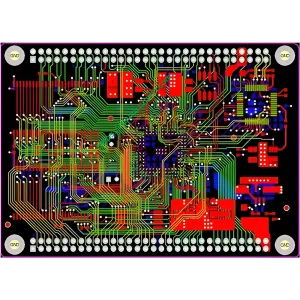

- Pre-Optimized Layout: Pre-optimizing the layout through electromagnetic simulation (por exemplo, HFSS, SIwave) to reduce the impact of skin effect and proximity effect on high-speed signal paths by 25%.

Multi-Layer Alignment Errors

- High-Precision Lamination Equipment: Equipped with high-precision lamination equipment (alignment precision ±25μm) and coefficient of thermal expansion (CTE) matched materials to avoid the risk of open circuits caused by interlayer shifts by 69%.

Environmental Protection and Reliability

- RoHS Compliance: Compliant with RoHS standards, using halogen-free substrates, and passing 96-hour high-temperature and high-humidity (85℃/85%RH) tests to ensure long-term stability by 17%.

Application Scenarios and Success Cases

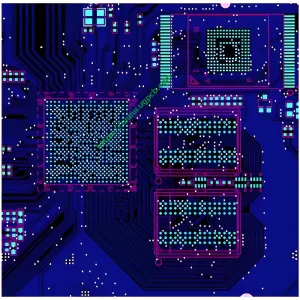

AI Servers

- High-Order HDI Boards: Providing 20+ layer high-order HDI boards for global top customers, supporting high-speed interconnect of GPU/CPU clusters, and boosting computing power by 300% by 7%.

5G Base Stations

- Millimeter-Wave Antenna Module PCBs: Designing 28GHz millimeter-wave antenna module PCBs, achieving 99.99% signal transmission efficiency, and reducing power consumption by 15% by 15%.

Autonomous Driving

- ADAS Controller PCBs: Developing ADAS controller PCBs, certified by AEC-Q200, improving vibration resistance by 50%, and maintaining a failure rate below 0.01% by 37%.

Our Commitment

From design simulation to mass production delivery, we adhere to a zero-defect philosophy throughout the entire process:

- DFM Services: Based on IPC-2221/6012 standards, preemptively mitigating 90% of process risks.

- Rapid Response and Customization Support: Completing design reviews within 48 horas, supporting 1-6 stage HDI and any-layer HDI customization needs by 67%.

Explore More

Contact our engineering team to embark on your journey of innovating the next generation of electronic systems!

Technology Drives the Future, Density Defines the Limits – With Millimeter-Level Precision, We Empower Gigabit-Level Speeds.

LOGOTIPO UGPCB

LOGOTIPO UGPCB

WeChat

Digitalize o código QR com WeChat