Composição de materiais

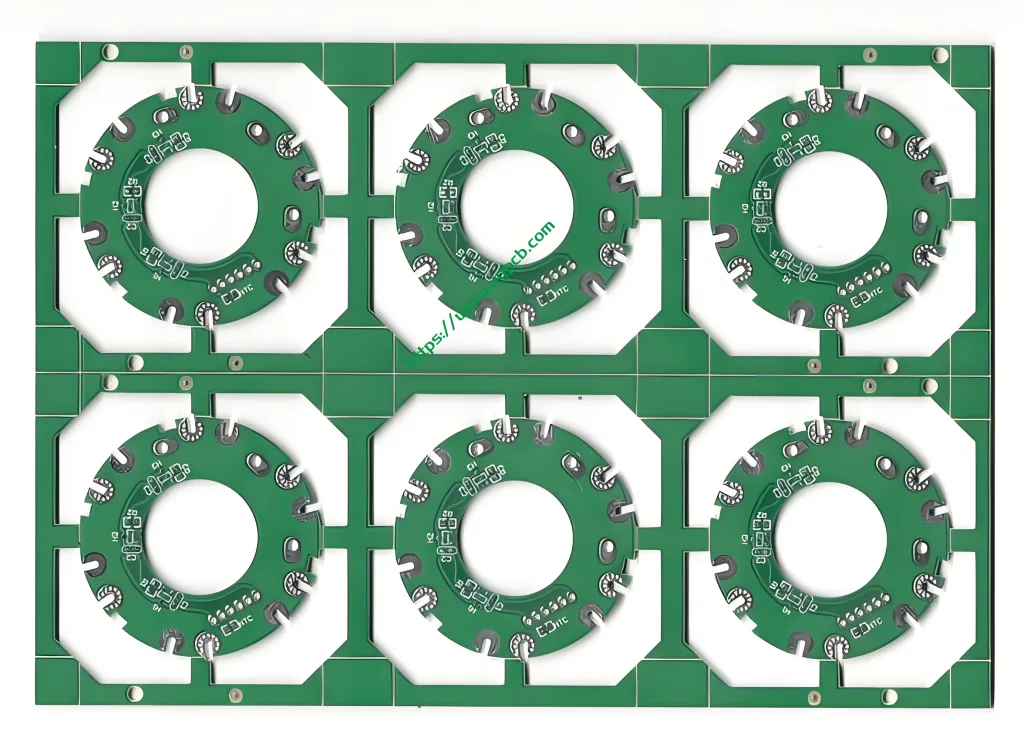

O 2 Layers Magnetic Coil PCB is designed specifically for winding purposes, primarily utilized in inductance components. It boasts a range of advantages, including high precision, exceptional linearity, and a straightforward structure. Despite its numerous benefits, the manufacturing process is challenging and often results in a high scrap rate due to the complexity involved.

Características de desempenho

This PCB excels in its ability to maintain precise windings, which is crucial for inductance components. Its high precision ensures accurate and reliable performance in various electronic applications. Adicionalmente, the PCB’s good linearity contributes to consistent and predictable electrical behavior, while its simple structure facilitates easy integration and assembly.

Processo de Produção

The production of 2 Layers Magnetic Coil PCBs involves several intricate steps:

- Design e layout: The PCB layout is carefully designed to accommodate the magnetic coil winding requirements.

- Preparação de Materiais: High-quality materials are selected to ensure the PCB’s durability and performance.

- Fabrication: The PCB is fabricated using advanced manufacturing techniques to meet the precise specifications.

- Winding: The magnetic coil is wound around the PCB with great care to maintain precision and uniformity.

- Teste: Rigorous testing procedures are conducted to ensure the PCB’s functionality and reliability.

Testing Methods

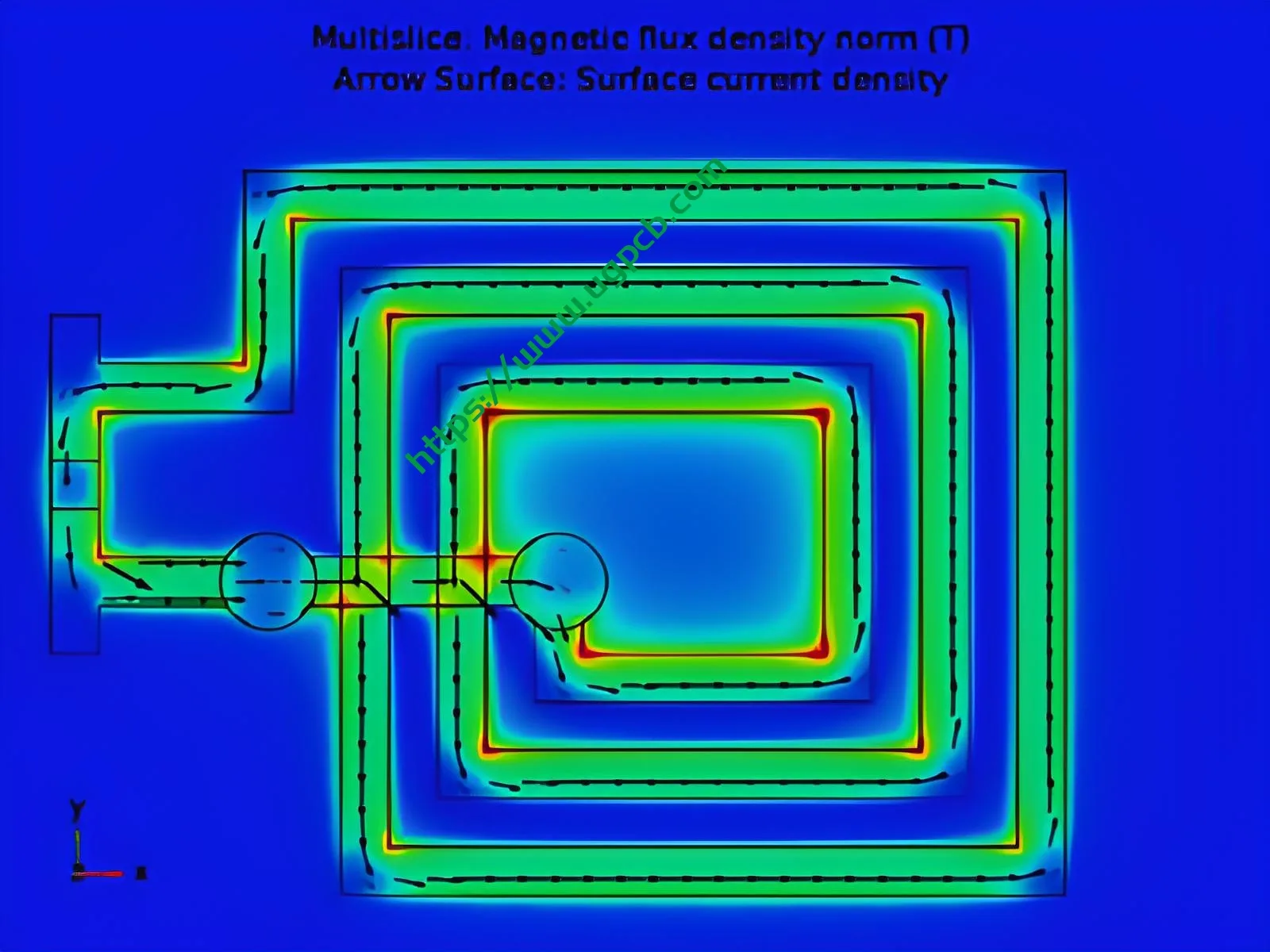

Testing is a vital part of the production process for 2 Layers Magnetic Coil PCBs. Several test methods are employed to ensure the PCB’s quality and performance:

- Ordinary Magnetic Coil PCB Test: A digital bridge is used to test the inductance online, with the frequency set above 10kHz to match the operating frequency of the inductance coil.

- Transformer Magnetic Coil PCB Test: By measuring the inductance D value of the transformer’s main coil, it can be determined whether there is a short circuit between turns. A digital bridge is set to 0.3V or below and 10kHz or above for this test.

- Hall Device Magnetic Coil PCB Detection: Hall sensors come in various types, and their outputs can be tested to determine if they are functioning correctly. This includes testing for current output, voltage output, and response to induced currents.

- Relay Magnetic Coil PCB Testing: Relay faults such as coil disconnection, contact failure, high contact resistance, and contact burnout can be detected by powering on the PCB and testing the continuity of the contacts.

Cenários de aplicação

O 2 Layers Magnetic Coil PCB finds applications in a wide range of industries and electronic devices, incluindo:

- Telecomunicações: In equipment that requires inductance components for signal processing and transmission.

- Automotive Industry: In sensors and control systems that rely on magnetic coils for functionality.

- Eletrônicos de consumo: In devices that utilize inductance components for power management and signal conditioning.

- Industrial Automation: In systems that use magnetic coils for motion control and positioning.

Conclusão

O 2 Layers Magnetic Coil PCB is a specialized product designed for winding in inductance components. Its high precision, good linearity, and simple structure make it an excellent choice for various electronic applications. Rigorous testing procedures ensure its reliability and performance, making it a valuable component in many industries.

LOGOTIPO UGPCB

LOGOTIPO UGPCB