Disadvantages of Rigid Flex PCB

Higher Cost Compared to Separate Components

If we only compare the hardware and software board with the software board + placa de circuito + conector, the biggest disadvantage is that the price of the software and hardware combination board is more expensive, which may be nearly twice as much as the original price of the simple software board and hard board. No entanto, if the price of the connector or hotbar is deducted, the price may tend to be the same. The detailed fees can be actuarially determined before a clearer outline is available.

Increased Assembly Cost During SMT

Another disadvantage is that the tray may be used to support the part of the soft board when SMT is beating or passing through the furnace, which increases the assembly cost of SMT.

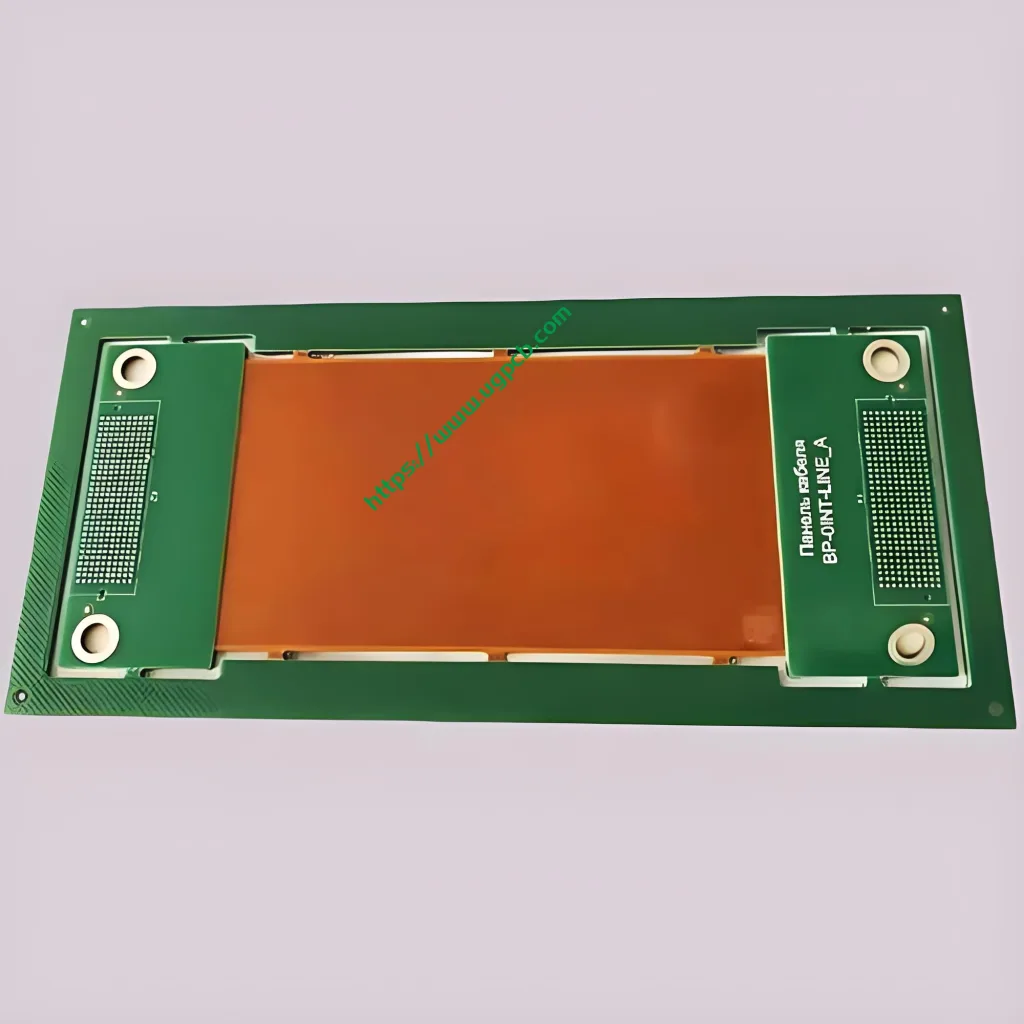

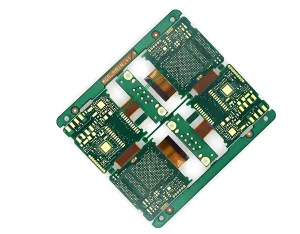

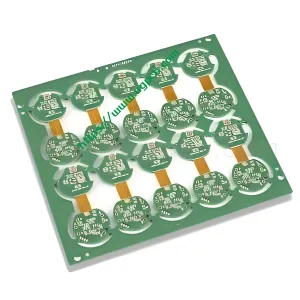

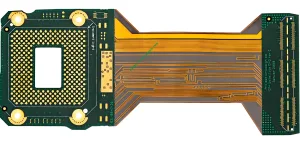

Flexible Printed Circuit Board (PCB) Visão geral

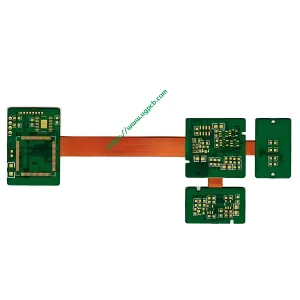

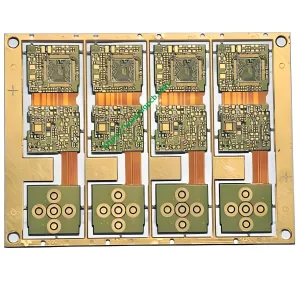

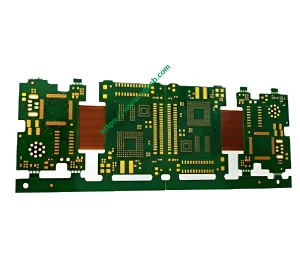

A flexible printed circuit board (PCB) is a special type of circuit board that can be bent to the desired application shape. Compared to ordinary rigid circuit boards, this type of circuit board places conductive paths and electrical components on a flex pcb prototype.

flex pcb prototype

(This section does not require a heading as it is a direct continuation of the previous section’s topic.)

Advantages of Rigid Flex PCB

Space and Cost Savings

In addition to the price, the use of rigid flex board has many advantages, como:

-

Space Savings: It can effectively save the space on the circuit board and the process of using a connector or hotbar. Because the hardware and software have been combined together, the space needed to use the connector or hotbar process can be saved. For some boards with high-density requirements, missing a connector space is like picking up a treasure.

-

Cost Savings: Desta maneira, the cost of using connector parts or hotbar process is saved. Além disso, the space between the two boards will be more compact because of the absence of connectors.

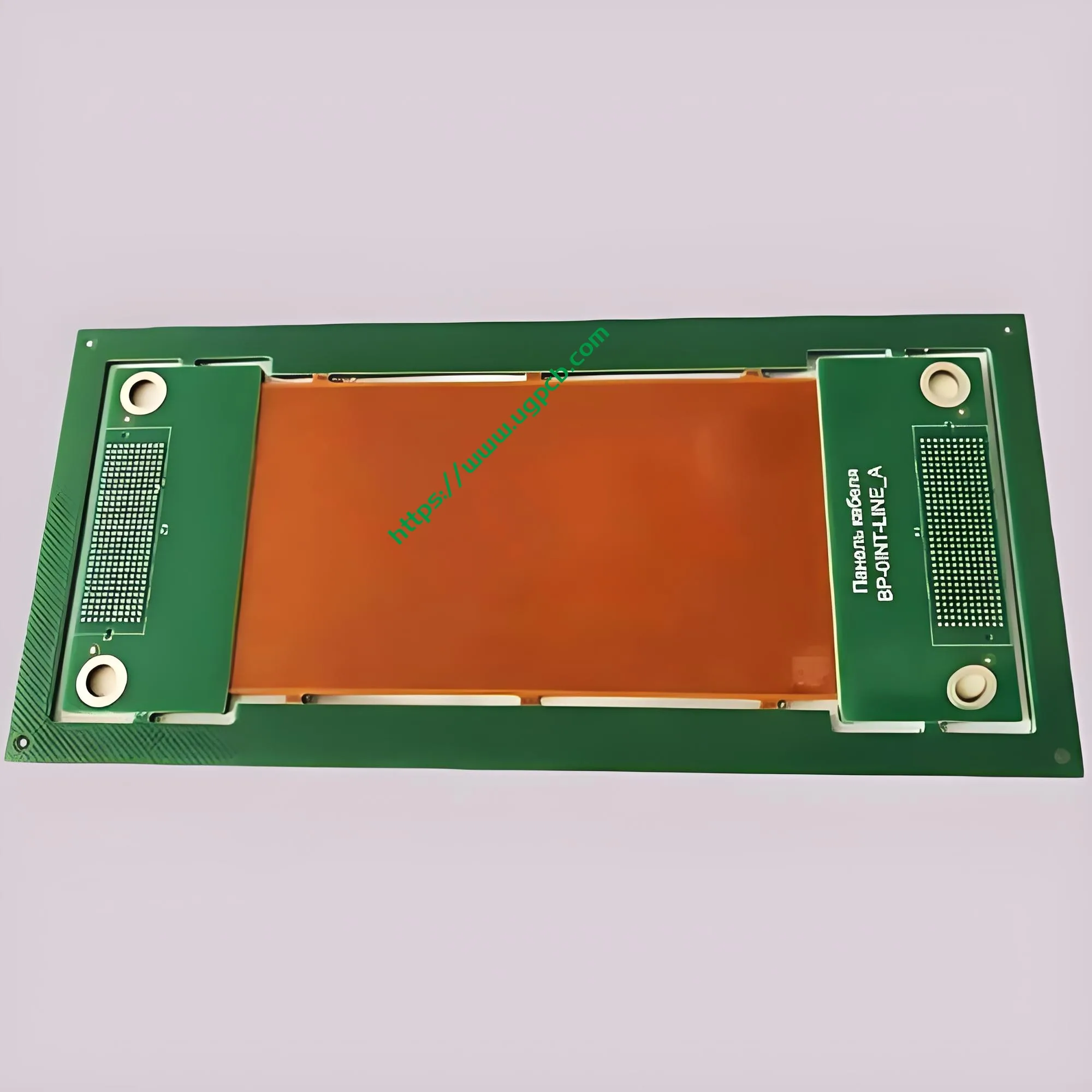

LOGOTIPO UGPCB

LOGOTIPO UGPCB