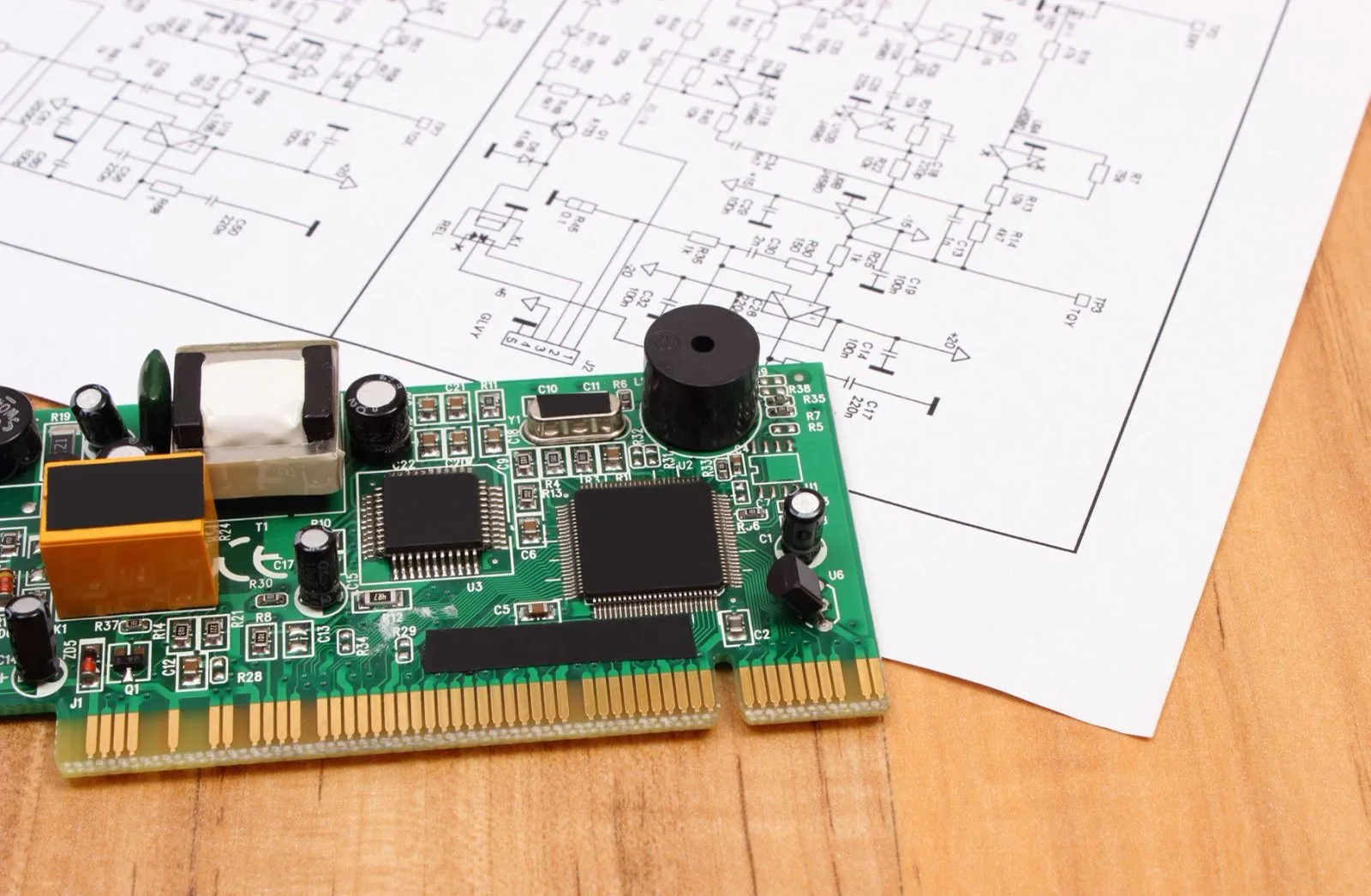

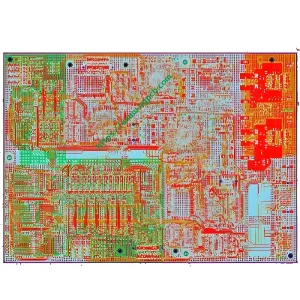

Versatilidade Extraordinária

As placas HDI são ideais quando o peso, espaço, confiabilidade, e desempenho são as principais preocupações.

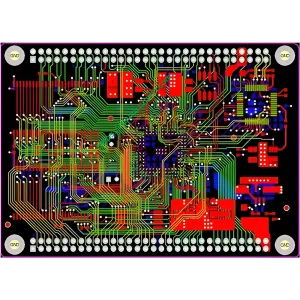

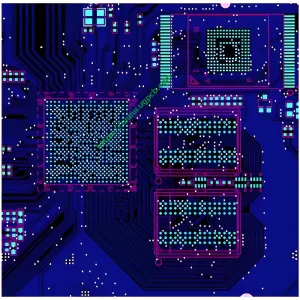

Design Compacto

Combinação de cego, Enterrado, e Micro Vias

A combinação de cego, enterrado, e micro vias reduzem os requisitos de espaço na placa.

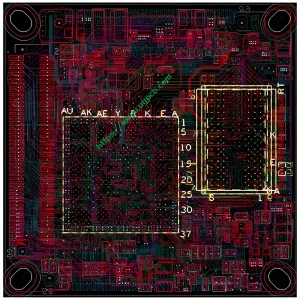

Melhor integridade de sinal

Tecnologia Via-in-Pad e Blind Via

HDI utiliza tecnologia via-in-pad e blind via, o que ajuda a manter os componentes próximos uns dos outros, reduzindo comprimentos do caminho do sinal.

Remoção de stubs de furo passante

A tecnologia HDI remove stubs de passagem, reduzindo reflexões de sinal e melhorando a qualidade do sinal.

Caminhos de sinal mais curtos

Devido aos caminhos de sinal mais curtos, HDI melhora significativamente a integridade do sinal.

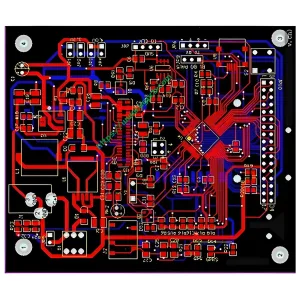

Alta confiabilidade

Vias empilhadas

A implementação de vias empilhadas torna estas placas uma superbarreira contra condições ambientais extremas.

Econômico

A funcionalidade de uma placa passante padrão de 8 camadas (PCB padrão) pode ser reduzido a uma placa HDI de 6 camadas sem comprometer a qualidade.

LOGOTIPO UGPCB

LOGOTIPO UGPCB