Introduction to HDI Mouse Bite PCB

IDH (Interconexão de alta densidade) technology is a significant advancement in the field of printed circuit boards (PCB), allowing for more complex and compact electronic designs. The HDI Mouse Bite PCB, specifically, is a high-density interconnect board designed with precision and efficiency in mind. This type of PCB is ideal for applications demanding high signal integrity, smaller form factors, and greater performance.

Definition and Design Requirements

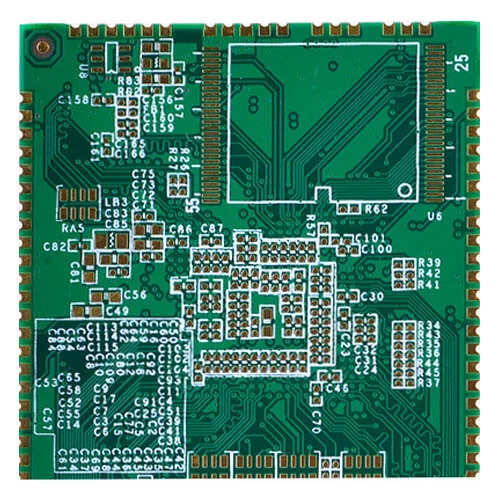

An HDI Mouse Bite PCB refers to a multilayer PCB that incorporates advanced fabrication techniques to achieve higher wiring density and finer features than standard PCBs. The term “mouse bite” describes the unique shape of the inner layers, which are staggered or “bitten” into to allow for more efficient space utilization. The design requirements for an HDI Mouse Bite PCB include precise layer stacking, tight tolerances, and specialized materials to ensure optimal performance and reliability.

Princípio de funcionamento

The working principle behind an HDI Mouse Bite PCB involves creating multiple layers of conductive material, separated by insulating layers, with intricate patterns etched onto each layer. These layers are then aligned and bonded together using heat and pressure. The unique “mouse bite” configuration allows for increased routing density by staggering the layers, reducing the need for vias and enhancing signal integrity.

Applications and Classifications

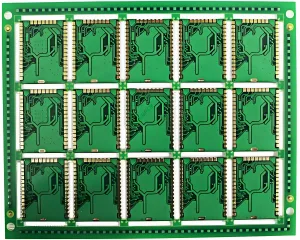

HDI Mouse Bite PCBs are primarily used in consumer electronics where space is at a premium, and performance is paramount. They are commonly found in smartphones, tablets, wearable devices, and other portable electronics. Based on their complexity and the number of layers, HDI PCBs can be classified into different categories, such as Type I, Type II, and Type III, each offering varying levels of density and functionality.

Materials and Performance

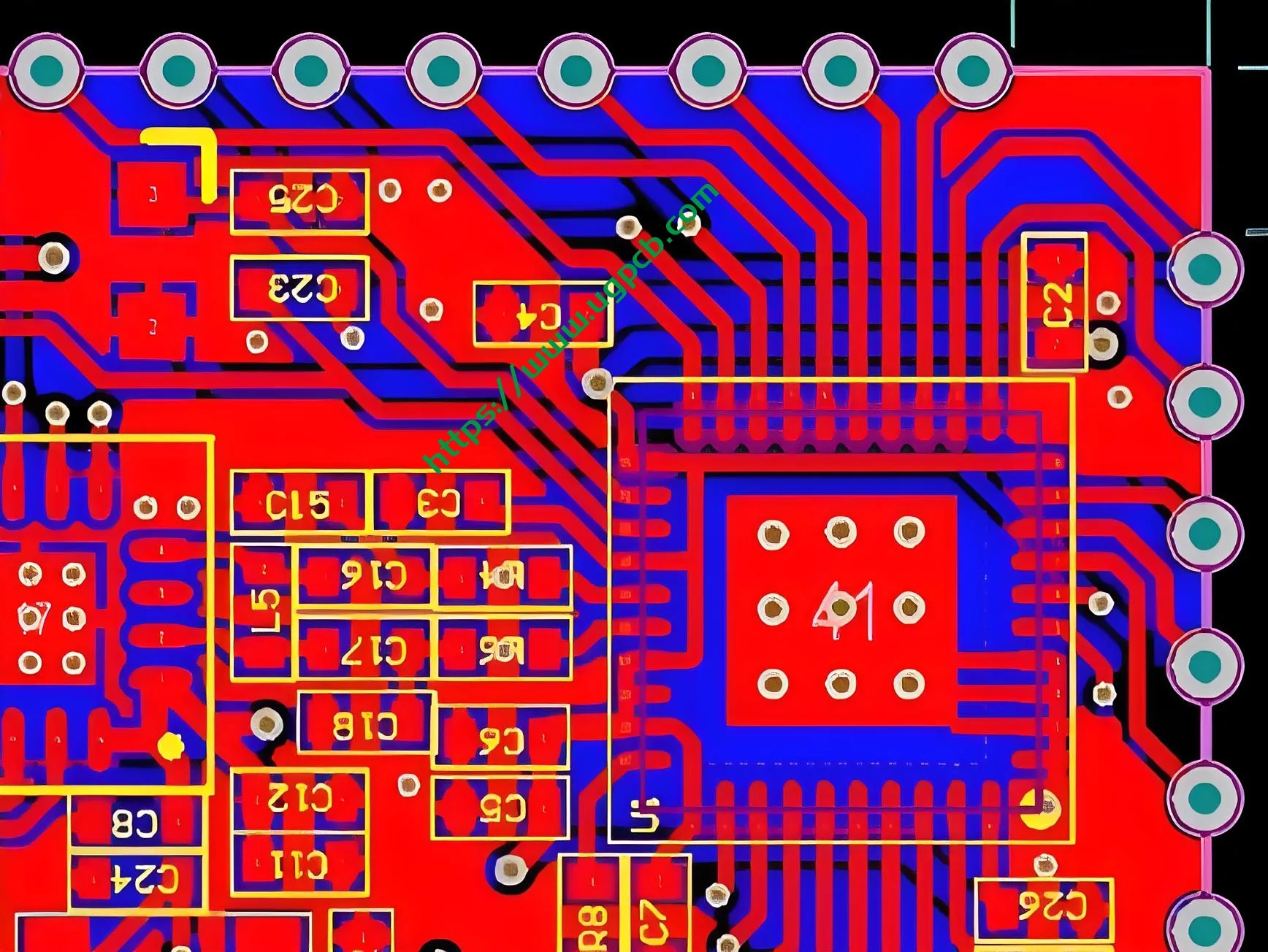

The HDI Mouse Bite PCB is constructed using high-quality materials like SY S1000-2, which provides excellent electrical properties and thermal stability. The finished thickness of 0.8mm ensures durability without compromising on the slim profile required for modern electronics. With a copper thickness of 1OZ/1OZ, these PCBs offer robust conductivity. The surface treatment, CONCORDAR (Electroless Nickel Immersion Gold), enhances solderability and corrosion resistance, ensuring long-term performance.

Structure and Features

The structure of an HDI Mouse Bite PCB includes multiple layers of conductive copper, precision-etched with fine traces and spaces as small as 3mil/3mil. The unique staggered layering, ou “mouse bite,” allows for increased routing density and improved signal integrity. Key features include high thermal conductivity, low dielectric constant, and superior mechanical strength, making them suitable for high-performance applications.

Processo de Produção

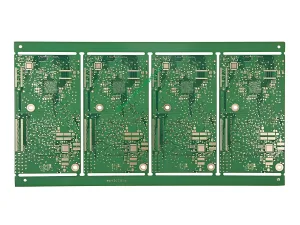

The production process of an HDI Mouse Bite PCB involves several sophisticated steps, incluindo:

- Preparação de Materiais: Selecting high-quality substrate materials and copper foils.

- Empilhamento de camada: Arranging the layers in a specific order to achieve the desired “mouse bite” effect.

- Bonding: Using heat and pressure to bond the layers together, forming a single, cohesive unit.

- Gravura: Applying etchant to remove excess copper, leaving only the desired conductive paths.

- Revestimento: Adding a thin layer of metal to the exposed copper to improve conductivity and solderability.

- Tratamento de superfície: Applying ENIG to protect against oxidation and enhance solderability.

- Controle de qualidade: Conducting thorough inspections and tests to ensure each board meets stringent quality standards.

Use Cases and Scenarios

HDI Mouse Bite PCBs are ideal for use in consumer electronics where miniaturization and high performance are critical. Common applications include:

- Smartphones: Enabling slimmer designs without compromising on functionality or performance.

- Tablets: Providing reliable connectivity for high-speed data transfer and processing.

- Wearable Devices: Supporting compact designs while maintaining robust performance and durability.

- Portable Media Players: Ensuring high-quality audio and video processing capabilities in a small form factor.

Para concluir, the HDI Mouse Bite PCB represents a pinnacle of innovation in PCB technology, offering unmatched density, desempenho, and reliability for the most demanding consumer electronic applications.

LOGOTIPO UGPCB

LOGOTIPO UGPCB