Introduction to Medical Device PCB

A placa de circuito impresso (PCB) o negócio expandiu sua influência benéfica irresistível devido ao crescimento contínuo do mundo da tecnologia e seu uso em vários campos. Nos últimos anos, seu impacto no mundo da eletrônica excedeu todas as previsões, incluindo dispositivos IoT, smartphones, computadores, inteligência artificial, e mais. Agora, Os PCBs estão transformando os dispositivos médicos e preenchendo a lacuna entre pacientes e médicos no negócio de tecnologia médica, enabling the development of convenient medical devices that help solve key challenges in healthcare.

The Growing Importance of PCBs in Medical Electronics

The medical electronics industry is growing rapidly and shows no signs of slowing down, highlighting the significant influence of PCBs in the medical field. The global medical electronics market is projected to reach $4.4 bilhão por 2022. With technological advancements, PCBs are becoming increasingly crucial in medical devices, as most modern medical gadgets require them to function properly and efficiently. PCBs are essential for operating medical equipment such as defibrillators, dispositivos de estimulação elétrica muscular, MRI machines, sistemas de imagens médicas, Tomografias computadorizadas, e equipamentos de ultrassom.

Tecnologia médica de PCB e seus tipos

Ensuring Reliability and Cleanliness

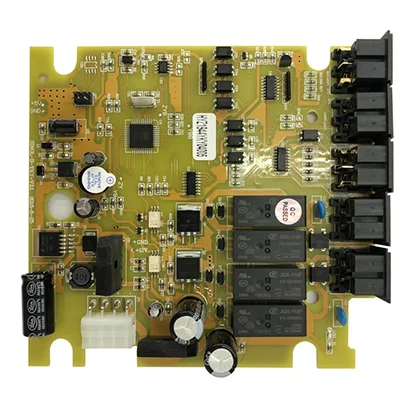

Extra care is taken in producing medical PCBs to ensure reliability, given that human life depends on the equipment they power. Medical PCBs must meet strict hygiene and cleanliness requirements, especially those used in implants. Interconexão de alta densidade (IDH) PCBs are commonly used in medical devices to achieve the necessary compactness and reliability.

Técnicas usadas na montagem de PCB médica

IDH / Via-in-Pad Technology

The design of inserting vias inside copper pads, known as via-in-pad, saves space on the PCB and provides up to 50% mais espaço para colocação de componentes. This technique is favored by PCB engineers for creating smaller, more acceptable pitch devices. Blind and buried vias also help reduce space, but via-in-pads remain the best choice for high-speed and high-dissipation PCBs.

Tecnologia de montagem em superfície

Tecnologia de montagem em superfície (SMT) is widely used in commercial device manufacturing due to its advantages in the PCB manufacturing process. SMT components are smaller, allowing more electronic devices to be packaged in a smaller space. SMT also enables automated soldering and PCB assembly, improving reliability and cost-effectiveness.

Linhas finas e espaços de PCB

Next-generation portable electronic devices rely on HDI PCB technology with tiny lines and spaces (2 mil e abaixo). This technology offers reduced board size, fiação aprimorada, and lower manufacturing costs compared to conventional techniques.

Application of UGPCB in the Healthcare Industry

UGPCB plays a vital role in the medical industry, not only in appliances but also in monitoring, diagnóstico, e equipamentos terapêuticos. With technological advancements, UGPCB’s applications in healthcare are rapidly expanding, abrindo novas possibilidades.

Common Applications

- Equipamento de digitalização: Tomógrafos, Telas de raios X, and ultrasound scans all rely on electronic components.

- Monitores: Dispositivos de monitoramento médico, como monitores de frequência cardíaca, monitores de glicose no sangue, e monitores de pressão arterial contêm componentes eletrônicos.

- Instrumentos Médicos: Medical research requires various instruments with PCBs, such as electron microscopes, sistemas de controle, and compressors.

Higher Standards and Quality Requirements

Devido a preocupações com a saúde, UGPCBs must meet higher standards in the medical industry. These devices must be reliable, of good quality, and often smaller in size to meet medical requirements.

Our Services

We provide Medical Equipment Turnkey PCB Assembly, medical PCB assembly, and Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly factory.

LOGOTIPO UGPCB

LOGOTIPO UGPCB