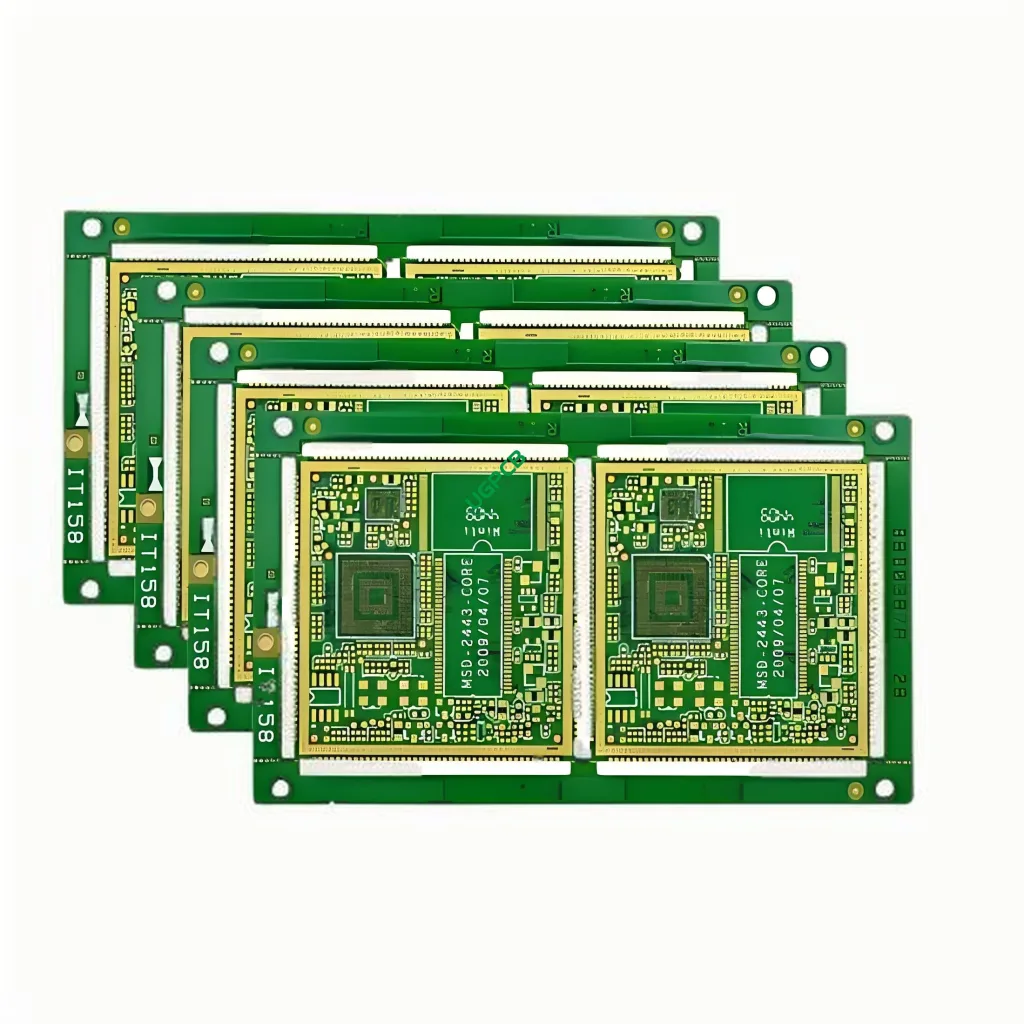

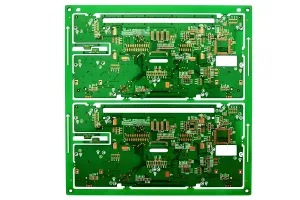

Overview of Multilayer Vehicle WiFi Module PCB

The multilayer vehicle WiFi module PCB is a specialized product designed to meet the stringent requirements of automotive WiFi and Bluetooth applications. Este tipo de PCB oferece alta precisão, confiabilidade, e desempenho, making it an ideal choice for various in-vehicle communication systems.

Definição

A multilayer vehicle WiFi module PCB is a printed circuit board specifically designed to support the functions of a WiFi or Bluetooth module in automotive applications. Consiste em múltiplas camadas de materiais condutores e isolantes, providing complex electrical pathways and connections essential for the operation of the module.

Requisitos de design

When designing a multilayer vehicle WiFi module PCB, Vários requisitos importantes devem ser atendidos:

- Qualidade do material: O material FR4 de alta qualidade é essencial para a durabilidade e a integridade do sinal.

- Configuração de camada: A 6-layer design is standard, permitindo circuitos complexos e roteamento de sinal.

- Espessura do Cobre: Uma espessura de cobre de 1 oz garante condutividade adequada.

- Tratamento de superfície: O tratamento da superfície de ouro de imersão aumenta a conectividade e a resistência à corrosão.

- Dimensões de rastreamento/espaço: Minimum trace and space dimensions of 3mil (0.75milímetros) são necessários para padrões precisos de circuito.

- Recursos especiais: O design do PCB de meio buraco é frequentemente incorporado para requisitos específicos de colocação e solda de componentes.

Princípio de funcionamento

The multilayer vehicle WiFi module PCB operates based on the principles of electrical conductivity and insulation. Camadas condutivas formam os caminhos para sinais elétricos, enquanto as camadas isolantes impedem interações indesejadas entre esses sinais. O tratamento da superfície de ouro de imersão fornece excelente conectividade e protege contra fatores ambientais.

Aplicações

This type of PCB is primarily used in automotive WiFi and Bluetooth modules, which are crucial components in various in-vehicle communication and entertainment systems. These include:

- In-vehicle WiFi hotspots

- Bluetooth connectivity for hands-free calling and audio streaming

- Telematics and remote diagnostics systems

- Infotainment systems

Classificação

Multilayer vehicle WiFi module PCBs can be classified based on their specific features and intended use, como:

- Communication Boards: For handling wireless communication signals in vehicles.

- Placas de controle: Para gerenciar e controlar várias funções em sistemas eletrônicos.

- Placas de distribuição de energia: Para gerenciar a fonte de alimentação em sistemas eletrônicos complexos.

Materiais

The primary materials used in the construction of a multilayer vehicle WiFi module PCB include:

- Material base: FR4, Um material de fibra de vidro retardista de chama conhecido por suas excelentes propriedades dielétricas e força mecânica.

- Material condutor: Cobre, usado para os traços condutores.

- Tratamento de superfície: Ouro de imersão, O que melhora a conectividade e fornece resistência à corrosão.

Desempenho

The performance of a multilayer vehicle WiFi module PCB is characterized by:

- Alta integridade do sinal: Devido a dimensões precisas de rastreamento/espaço e materiais de qualidade.

- Conectividade confiável: Garantido pelo tratamento da superfície de ouro de imersão.

- Durabilidade: Aprimorado pelo material robusto de base FR4.

- Eficiência elétrica: Perda de sinal minimizada e interferência devido à configuração da camada otimizada.

Estrutura

The structure of a multilayer vehicle WiFi module PCB consists of:

- Six Layers of Conductive Material: Alternando com camadas isolantes.

- Tratamento da superfície de ouro de imersão: Para conectividade e proteção aprimoradas.

- Design de meio buraco: Para requisitos específicos de colocação e solda de componentes.

Características

Key features of the multilayer vehicle WiFi module PCB include:

- Tratamento de superfície avançado: Ouro de imersão para qualidade de conexão superior.

- Alta precisão: With minimum trace and space dimensions of 3mil (0.75milímetros).

- Opções de cores personalizáveis: Disponível em verde ou branco.

- Espessura padrão: Com uma espessura acabada de 1,0 mm.

Processo de Produção

The production process for a multilayer vehicle WiFi module PCB involves several steps:

- Preparação de Materiais: Selecionando e preparando folhas FR4 e folha de cobre.

- Empilhamento de camada: Camadas alternadas de materiais de cobre e isolantes.

- Gravura: Removendo o excesso de cobre para formar o padrão de circuito desejado.

- Revestimento: Aplicando tratamento de superfície de ouro de imersão.

- Laminação: Combinando as camadas sob calor e pressão.

- Perfuração: Criando orifícios para componentes e vias do orifício por meio.

- Aplicação de máscara de solda: Protegendo o circuito de pontes de solda e fatores ambientais.

- Impressão de seda: Adicionando texto e símbolos para a colocação e identificação dos componentes.

- Controle de qualidade: Garantir que o PCB atenda a todas as especificações e padrões de design.

Use cenários

The multilayer vehicle WiFi module PCB is ideal for scenarios where:

- A alta integridade do sinal é crucial.

- Conexões confiáveis e duráveis são necessárias.

- Restrições de espaço exigem um design compacto e eficiente.

- O tratamento de superfície avançado é necessário para um desempenho aprimorado.

LOGOTIPO UGPCB

LOGOTIPO UGPCB