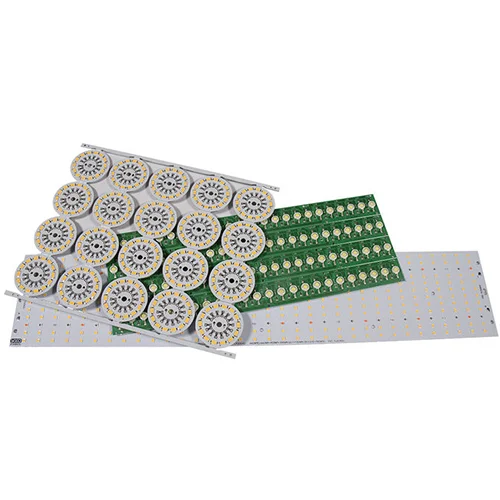

UGPCB’s 10W 56mm aluminum plate PCB component utilizes high-quality chips and PCB materials to ensure extended service life. We welcome your inquiries and orders.

Product Features:

Material: High-purity aluminum board with FR-4, CEM-3, or aluminum substrate options.

Contagem de camadas: Available in 1 para 22 camadas.

Maximum Panel Size: 1550mm x 800mm.

Copper Thickness Options: 0.5onças, 1onças, 2onças, 3onças, 4onças.

Espessura dielétrica: 0.05milímetros, 0.075milímetros, 0.1milímetros, 0.15milímetros, 0.2milímetros.

Core Thickness: 0.4milímetros, 0.6milímetros, 0.8milímetros, 1.0milímetros, 1.2milímetros, 1.5milímetros, 2.0milímetros, 3.0milímetros, 3.2milímetros.

Espessura da placa: Ranges from 0.4mm to 4.0mm.

Thickness Tolerance: +/-10%.

Processing Services: Perfuração, tapping, milling, perfuração, folding available.

Minimum Track Width: 0.2milímetros (8mil).

Minimum Track Gap: 0.2milímetros (8mil).

Minimum SMD Pad Pitch: 0.2milímetros (8mil).

Aluminum Board Definition and Classification:

Definição:

Aluminum boards are aluminum materials with a thickness greater than 0.2mm and less than 500mm, a width greater than 200mm, and a length of less than 16m. With the advancement of large-scale equipment, aluminum boards up to 600mm wide are increasingly common.

Classificação:

By Alloy Composition:

High-purity aluminum board (composed of more than 99.9% pure aluminum).

Pure aluminum board (essentially composed of pure aluminum).

Alloy aluminum board (composed of aluminum and auxiliary alloys such as aluminum-copper, aluminum-manganese, aluminum-silicon, aluminum-magnesium, etc.).

Composite aluminum board or welded board (special aluminum board material composed of multiple materials).

Aluminum clad aluminum board (aluminum board clad with thin aluminum for special purposes).

By Thickness (units in mm):

Thin plate (aluminum plate) 0.15-2.0.

Ordinary plate (aluminum plate) 2.0-6.0.

Medium plate (aluminum plate) 6.0-25.0.

Thick plate (aluminum plate) 25-200.

Super thick plate 200 and above.

Common Terminology:

Brushed Aluminum Plate: Produced by repeatedly scraping an aluminum plate that does not conform to line patterns with sandpaper. The process includes degreasing, sanding, and washing. Anodizing during the brushing process can create a metallic film on the surface, clearly revealing fine lines and giving the metal a silky luster.

Anodized Aluminum Plate: Formed by electrolyzing the aluminum plate in a specific electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) under certain conditions and applied current. After anodizing treatment, the surface forms a thin layer of aluminum oxide, typically 5-20 microns thick, with hard anodizing films reaching 60-200 microns.

PS Aluminum Plate (Advertising Aluminum Plate also known as Printed Zinc Plate, Newspaper Plate): An aluminum plate with a pattern printed on the back, usually 025 ou 03 material thickness.

Mirror Aluminum Plate: Processed through rolling, grinding, and other methods to achieve a mirror effect on the surface of the aluminum plate.

Embossed Aluminum Plate: Also known as aluminum embossed sheet, which is processed by rolling and pressing patterns on the surface of the aluminum plate. Widely used in packaging, construção, building curtain walls, etc..

LOGOTIPO UGPCB

LOGOTIPO UGPCB