What is PCBA board?

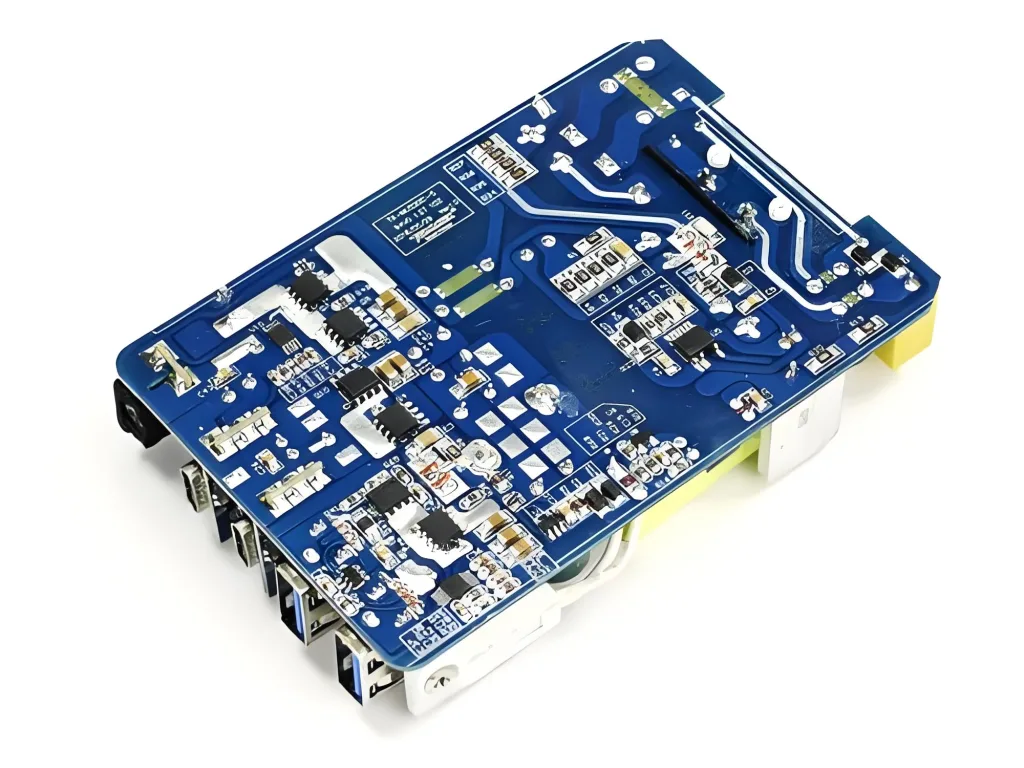

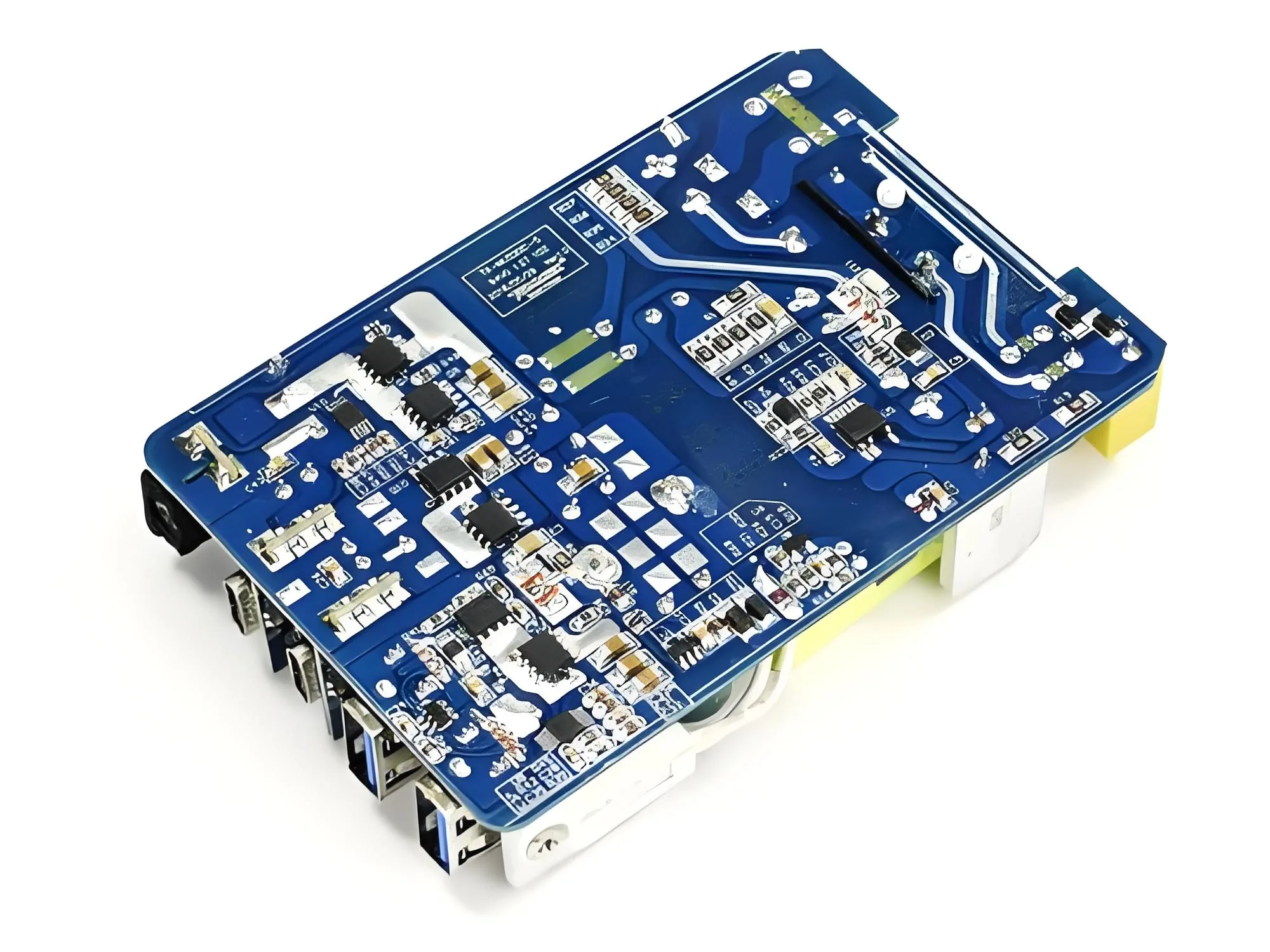

PCBA board is short for printed circuit board assembly board. The difference from PCB board is that PCB board has no electronic components and PCBA board has electronic components.

Isso quer dizer, PCBA board includes PCBA circuit board, PCBA control board, PCBA printed circuit board, printed circuit board assembly PCBA.

pcba board

UGPCB strictly abides by the confidentiality of customers’ documents and process flow. After more than ten years of development, UGPCB has accumulated a mature PCBA board process control scheme. This process control is not only suitable for PCBA board processing but also can be used for electronic manufacturing services, new product introduction, engineering change, BGA repair and other maintenance services. Through the incoming quality control (IQC), in-process quality control (IPQC), and outgoing quality assurance (IQC), the quality control system (IPQC) and the quality assurance system (IQC) are adopted, The implementation of quality control processes such as OQA, PDCA and 6sigma will form a hierarchical document, which will be implemented in each electronic manufacturing post, with clear responsibilities and efficient implementation, which will be conducive to the control of the quality standards of the whole PCBA board production, SMT chip processing, ICT testing and other important links.

According to IPC standards and the ISO9001 document management system, UGPCB regulates the core process of electronic manufacturing, forms controlled documents, issues them to relevant posts, and forms effective supervision and improvement mechanism; meanwhile, UGPCB has rich experience in foreign customer audits and can effectively regulate manufacturing process and quality control according to international standards, thus forming a perfect PCBA board patch Process management system and process flow.

PCBA board electronic products processing involves a series of production and supply chains, such as design document inspection, component procurement, PCB board production, SMT placement, plug-in processing, PCBA board testing, packaging and so on, which needs professional suppliers to control. UGPCB gives full play to decades of experience in this field, selects a + grade plate, fully automatic production process, 100% factory inspection, and uses high-end SMT production equipment and strict ISO standard operation guidance to ensure the advantages of process flow and team in the manufacturing process.

Advantages of UGPCB in PCBA board electronic products processing service

PCBA board industry needs to have a strong overall technical strength, process technology, quality control level and production management technology are very important, need a long time of practice and accumulation.

1. 8 fully automatic SMT production lines and dip production lines, high production capacity and high precision equipment;

2. Professional manufacturing team with many years of working experience and regular training;

3. Adapt to high-end manufacturing, provide channels for the majority of small and medium-sized enterprises to produce high-end products, and save 20% of the cost compared with other processors;

In order to save production costs and seek preferential and competent PCBA board electronic products processing service providers, China has obviously become the preferred processing site. As the leader of PCBA board electronic products processing industry in Shenzhen, UGPCB can save 20% on production costs and provide 100% testing for customers. We formulate development and competition strategies that are in line with our own development and the current situation, develop technological innovation, and make us stand out in the competition. If you need PCBA board service or PCBA board technical support, Entre em contato conosco.

LOGOTIPO UGPCB

LOGOTIPO UGPCB