Visão geral

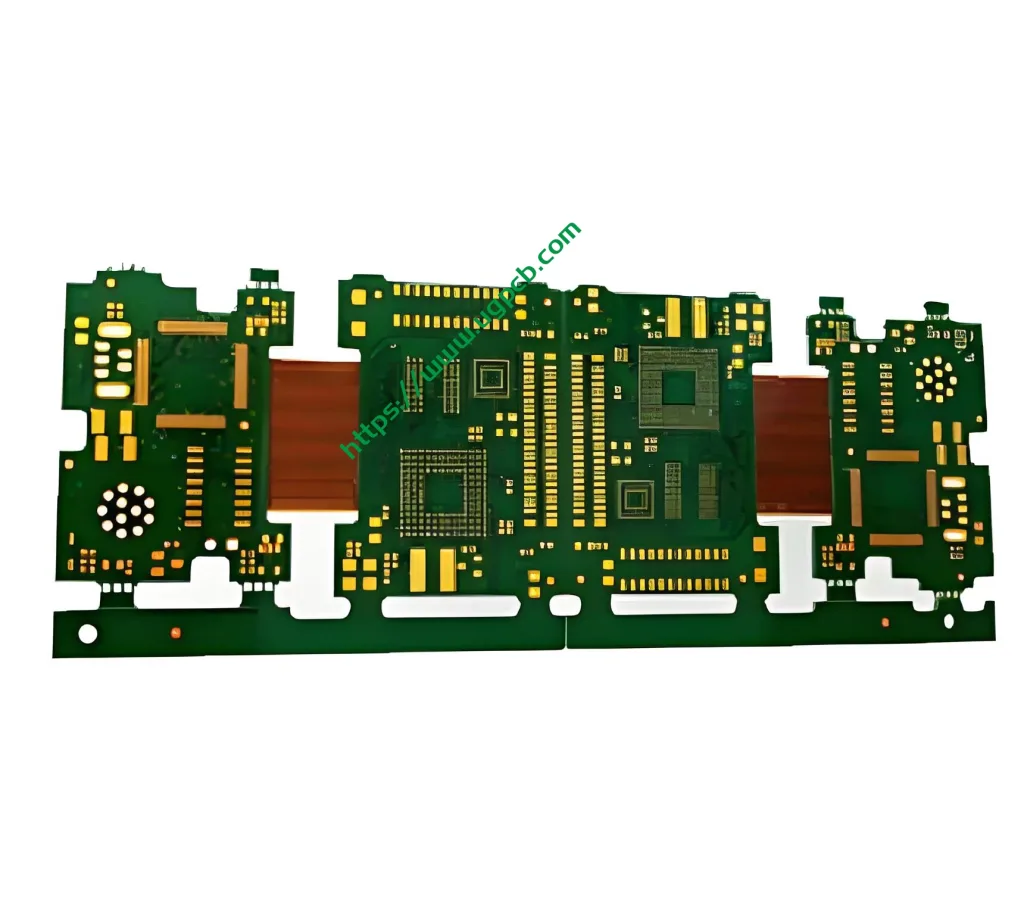

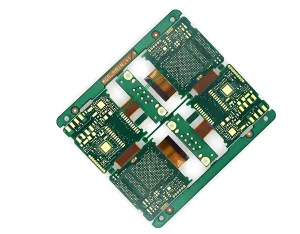

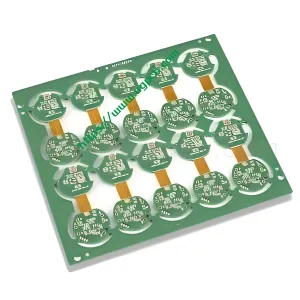

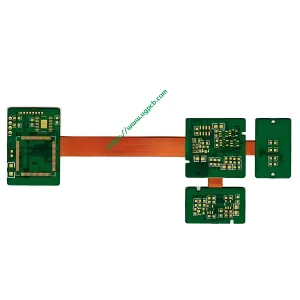

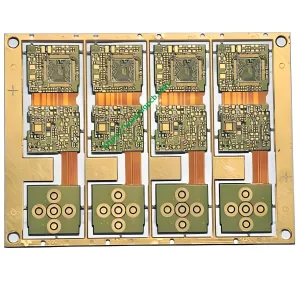

Rigid-flex PCB is a new type of printed circuit board that combines the durability of rigid PCB and the adaptability of flexible PCB. This combination makes it the most resistant to harsh application environments among all types of PCB, earning it favor from manufacturers of industrial control PCB, medical PCB, and military equipment PCB.

Process Classification

Soft and Hard Composite Board

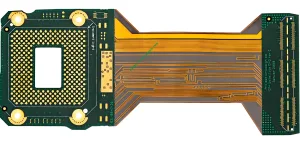

If classified by process, a forma de unir a placa macia e a placa dura pode ser dividida em duas categorias: a placa composta macia e dura e a placa combinada macia e dura. The soft and hard composite board technology allows the soft board and the hard board to be combined during the process, often incorporating blind hole and buried hole designs. This enables the adoption of higher-density circuit designs.

Soft and Hard Combination Board

The technology of the soft and hard combination board involves separating the soft board from the hard board after fabrication and then pressing them together to form a single circuit board. This design includes signal connections but no through holes.

Material, Equipamento, and Process Differences

Materiais

There are differences in materials between hard and soft boards. The material of the hard board is FR4, which is commonly used in PCB manufacturing. The material of the soft board is PI or PET. The joint between these two materials presents a challenge due to their different hot compression shrinkage rates, which can affect product stability.

Stress Considerations

Due to the three-dimensional space configuration of soft and hard PCB, in addition to considering XY-axis stress, Z-axis stress bearing is also an important consideration. To address this, alguns fornecedores de materiais fornecem materiais aprimorados para fabricantes de placas rígidas e flexíveis de PCB, such as epoxy resin or modified resin, to meet the bonding requirements of hard and soft boards.

Wide Applications of Rigid-Flex PCB

UGPCB’s rigid-flex PCB is widely used in various applications, incluindo:

- Produtos inteligentes vestíveis

- Semiconductor PCB

- Digital camera PCB

- Tablet computer PCB

- Mobile phone PCB

- Module PCB

- Navigation PCB

- Automobile brake system PCB

- Placa IC PCB

- PCB do cartão T

- PCB SSD

- Graphics card PCB

- Solid state disk PCB

- Battery PCB board

- PCB Wi-Fi

- Camera lens PCB

- Industrial control PCB

LOGOTIPO UGPCB

LOGOTIPO UGPCB