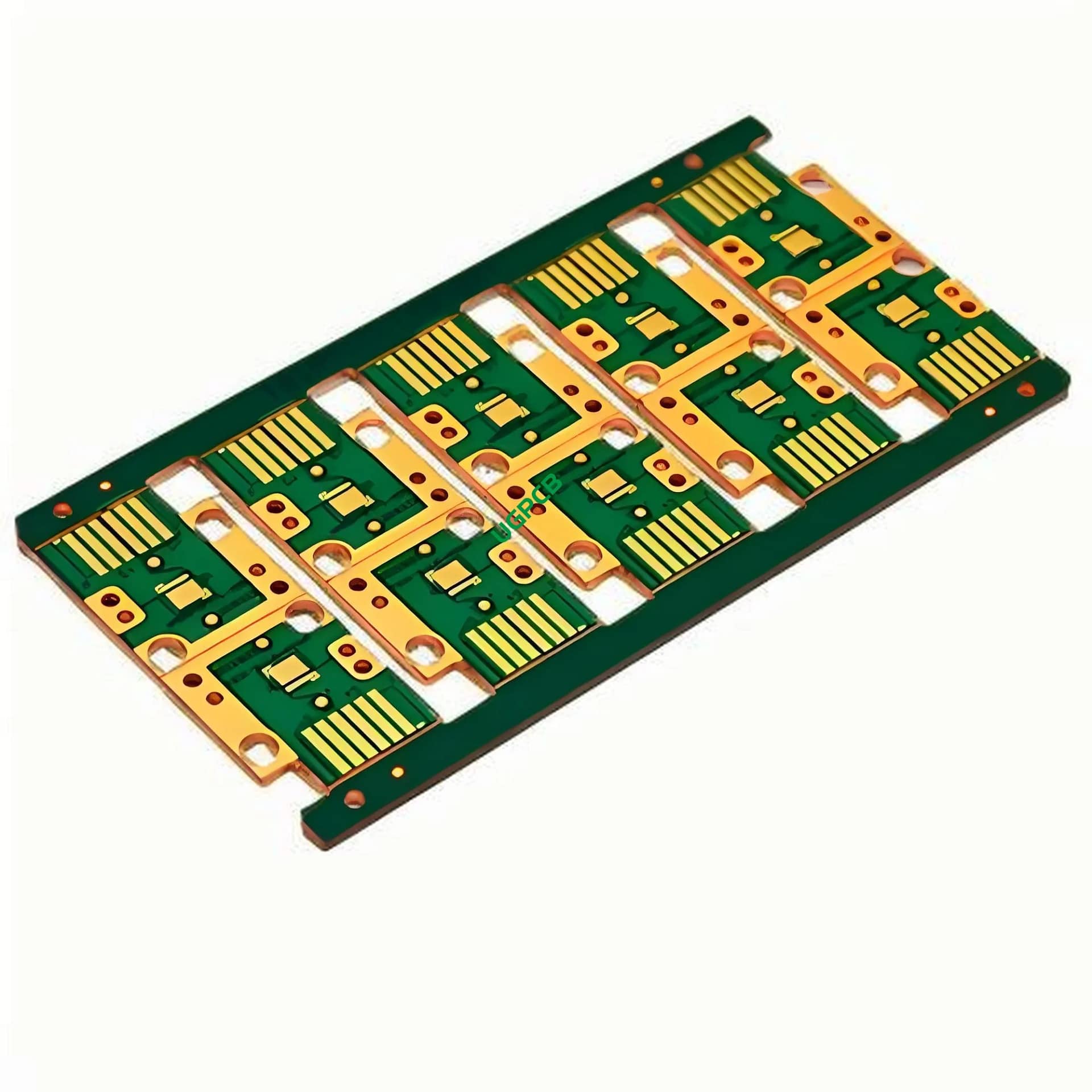

Overview of 12OZ Heavy Copper PCB for Power Supply

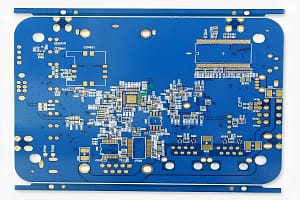

The 12OZ Heavy Copper PCB for power supply is a specialized product designed to meet the stringent requirements of power supply applications. This type of PCB offers high current-carrying capacity, thermal stability, and reliability, making it an ideal choice for various power electronics devices.

Definiţie

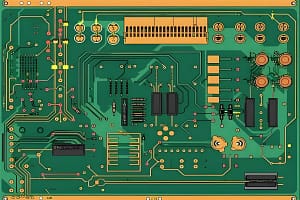

A 12OZ Heavy Copper PCB for power supply is a printed circuit board specifically designed to support the functions of a power supply unit. Este format din mai multe straturi de materiale conductoare și izolante, providing complex electrical pathways and connections essential for the operation of the power supply. The term “12Oz” refers to the copper weight, indicating that the copper layer is significantly thicker than standard PCBs, allowing it to handle higher currents and dissipate more heat.

Cerințe de proiectare

When designing a 12OZ Heavy Copper PCB for power supply, Mai multe cerințe cheie trebuie îndeplinite:

- Calitatea materialelor: High-quality FR4 material is essential for durability and thermal stability.

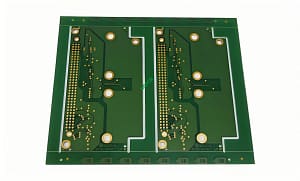

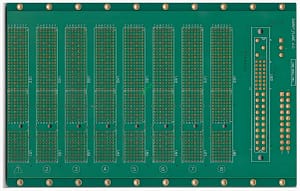

- Configurare strat: A 2-layer design is standard, allowing for efficient routing of power and ground planes.

- Grosime de cupru: A copper thickness of 1OZ ensures adequate conductivity and thermal management.

- Tratament de suprafață: Tratamentul de suprafață de aur imersie îmbunătățește conectivitatea și rezistența la coroziune.

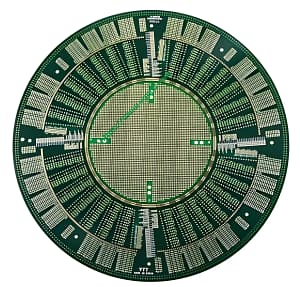

- Dimensiuni de urmărire/spațiu: Minimum trace and space dimensions of 40mil (1mm) sunt necesare pentru modelele precise de circuit.

- Caracteristici speciale: 2OZ Heavy Copper Design PCB is often incorporated for specific component placement and soldering requirements.

Principiul de lucru

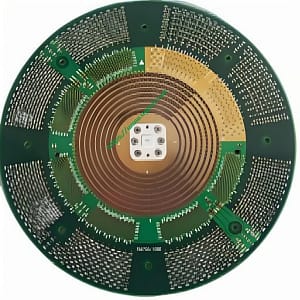

The 12OZ Heavy Copper PCB for power supply operates based on the principles of electrical conductivity and thermal management. Straturile conductoare formează căile semnalelor electrice, în timp ce straturile izolante previn interacțiunile nedorite între aceste semnale. The heavy copper layer provides low resistance paths for high currents and helps dissipate heat generated by power components. Tratarea suprafeței de aur de imersiune oferă conectivitate excelentă și protejează împotriva factorilor de mediu.

Aplicații

This type of PCB is primarily used in power supply units, care sunt componente cruciale în diverse dispozitive electronice, cum ar fi computerele, servere, telecommunications equipment, and industrial machinery. Acestea includ:

- Power adapters and chargers

- DC-DC converters

- AC-DC power supplies

- Uninterruptible Power Supplies (UPS)

- Motor controllers

Clasificare

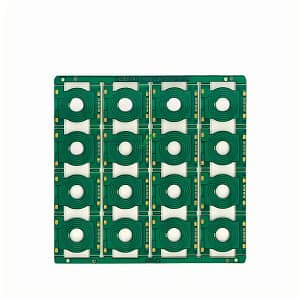

12OZ Heavy Copper PCBs for power supply can be classified based on their specific features and intended use, ca:

- High Current Carrying Boards: For handling large currents in power distribution systems.

- Thermal Management Boards: To efficiently dissipate heat generated by power components.

- Panouri de control: For managing and controlling various functions in power electronics systems.

Materiale

The primary materiale used in the construction of a 12OZ Heavy Copper PCB for power supply include:

- Material de bază: FR4, Un material din fibră de sticlă retardant de flacără cunoscut pentru proprietățile sale dielectrice excelente și rezistența mecanică.

- Material conductiv: Cupru, Folosit pentru urmele conductoare.

- Tratament de suprafață: Aur de imersiune, care îmbunătățește conectivitatea și oferă rezistență la coroziune.

Performanţă

The performance of a 12OZ Heavy Copper PCB for power supply is characterized by:

- High Current-Carrying Capacity: Due to the thick copper layer, which allows it to handle higher currents without significant voltage drop or overheating.

- Enhanced Thermal Stability: The heavy copper layer helps dissipate heat more effectively, maintaining stable operating temperatures.

- Conectivitate fiabilă: Asigurat de tratamentul suprafeței din aur de imersiune.

- Durabilitate: Enhanced by the robust FR4 base material.

- Eficiență electrică: Pierderea minimizată a semnalului și interferența datorită configurației optimizate a stratului.

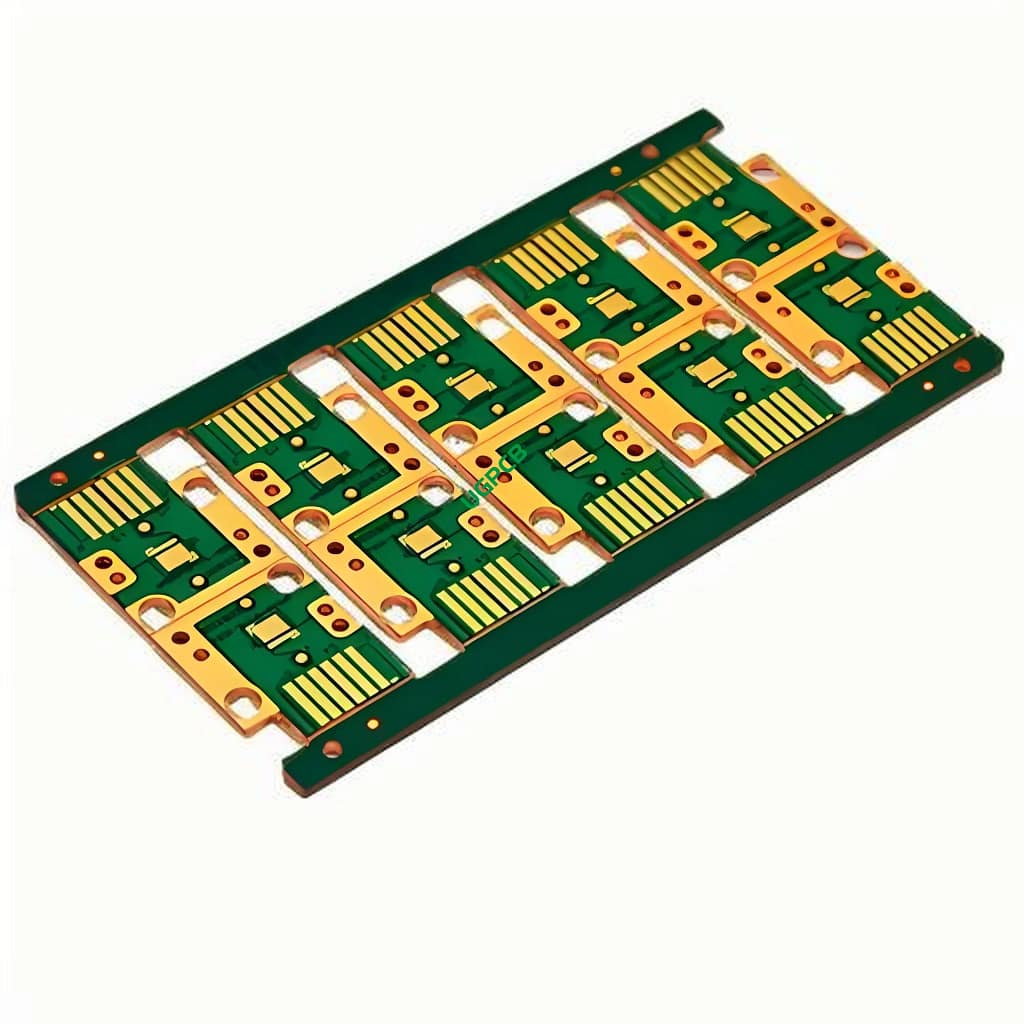

Structura

The structure of a 12OZ Heavy Copper PCB for power supply consists of:

- Two Layers of Conductive Material: Alternând cu straturi izolante.

- Tratarea suprafeței din aur de imersiune: Pentru conectivitate și protecție sporită.

- Heavy Copper Design: Pentru cerințele specifice de plasare și lipire a componentelor.

Caracteristici

Key features of the 12OZ Heavy Copper PCB for power supply include:

- Advanced Copper Weight: 2OZ Heavy Copper for superior current-carrying capacity.

- Precizie înaltă: With minimum trace and space dimensions of 40mil (1mm).

- Opțiuni de culoare personalizabile: Available in black or white.

- Grosime standard: With a finished thickness of 2.0mm.

Proces de producție

The production process for a 12OZ Heavy Copper PCB for power supply involves several steps:

- Pregătirea materialelor: Selectarea și pregătirea foilor FR4 și a foliei de cupru.

- Stivuirea stratului: Combining the copper and insulating layers.

- Gravură: Eliminarea excesului de cupru pentru a forma modelul de circuit dorit.

- Placare: Aplicarea tratamentului de suprafață a aurului de imersiune.

- Laminare: Combinarea straturilor sub căldură și presiune.

- Foraj: Crearea de găuri pentru componente și vias prin gaură.

- Aplicație de mască de lipit: Protejarea circuitului împotriva podurilor de lipit și a factorilor de mediu.

- Imprimare cu mătase: Adăugarea de text și simboluri pentru plasarea și identificarea componentelor.

- Controlul calității: Asigurarea că PCB îndeplinește toate specificațiile și standardele de proiectare.

Folosiți scenarii

The 12OZ Heavy Copper PCB for power supply is ideal for scenarios where:

- High current-carrying capacity is crucial.

- Sunt necesare conexiuni fiabile și durabile.

- Effective thermal management is necessary to maintain stable operating temperatures.

- Tratamentul avansat de suprafață este necesar pentru o performanță sporită

LOGO UGPCB

LOGO UGPCB