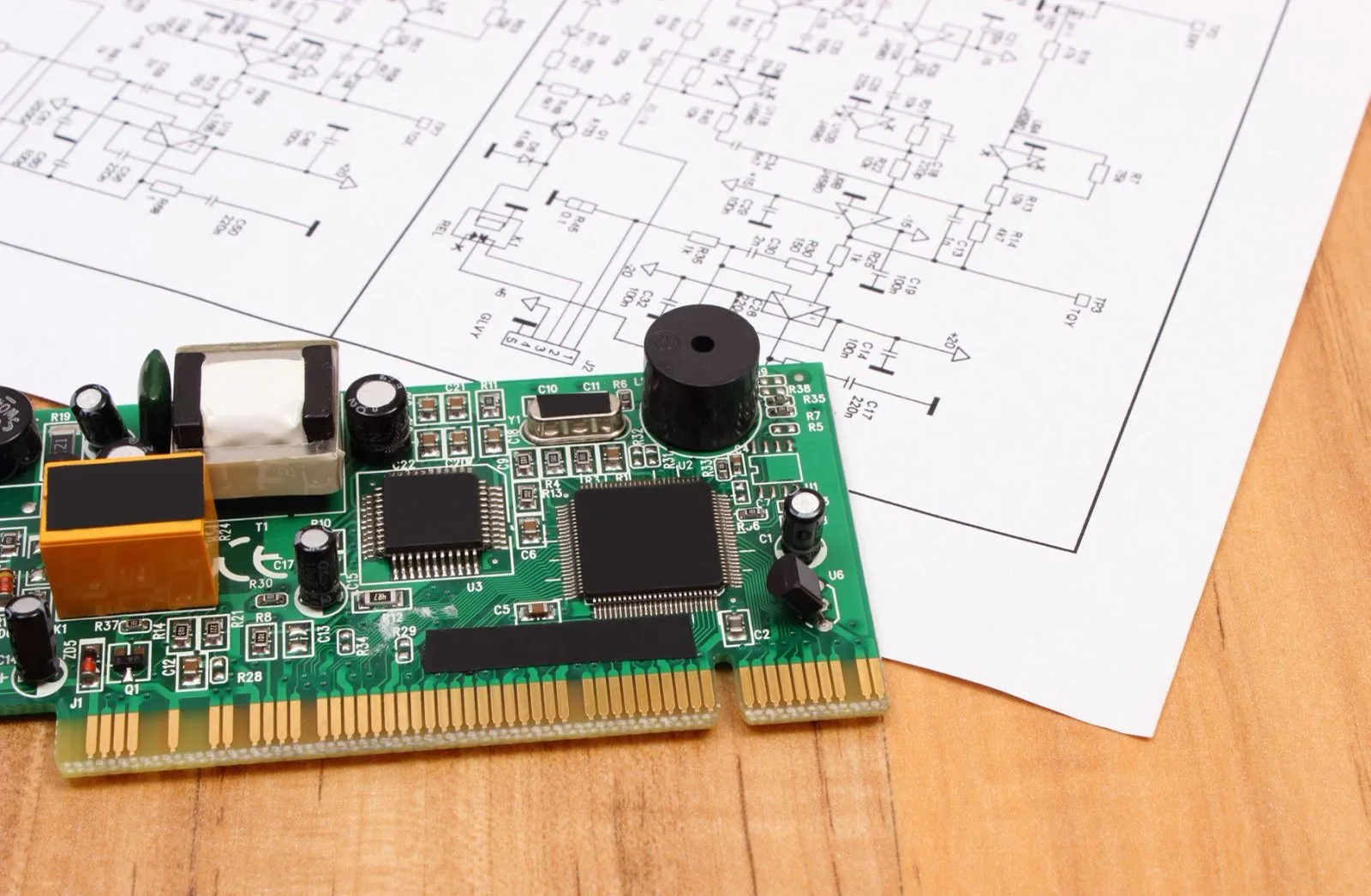

Extraordinary Versatility

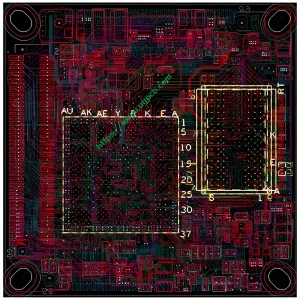

HDI boards are ideal when weight, space, reliability, and performance are the main concerns.

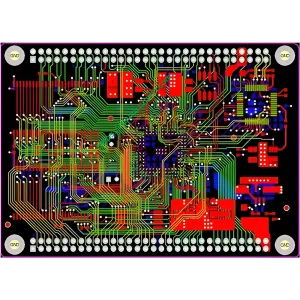

Compact Design

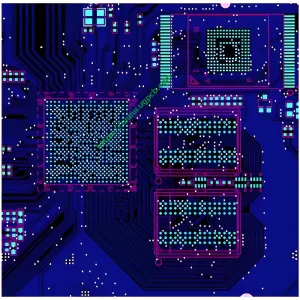

Combination of Blind, Buried, and Micro Vias

The combination of blind, buried, and micro vias reduces board space requirements.

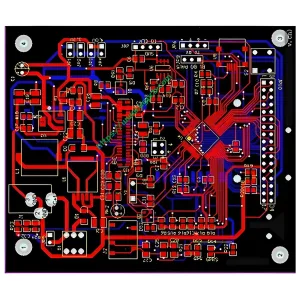

Better Signal Integrity

Via-in-Pad and Blind Via Technology

HDI utilizes via-in-pad and blind via technology, which helps keep components close to each other, reducing signal path lengths.

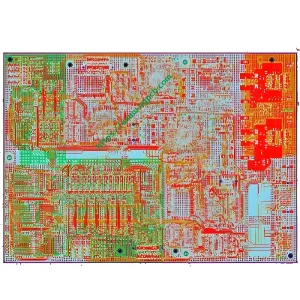

Removal of Through-hole Stubs

HDI technology removes through-hole stubs, reducing signal reflections and improving signal quality.

Shorter Signal Paths

Due to shorter signal paths, HDI significantly improves signal integrity.

High Reliability

Stacked Vias

The implementation of stacked vias makes these boards a super barrier against extreme environmental conditions.

Cost-effective

The functionality of a standard 8-layer through-hole board (standard PCB) can be reduced to a 6-layer HDI board without compromising quality.

LOGO UGPCB

LOGO UGPCB