Teflon high-frequency microwave PCB board

The PCB material used by teflon PCB, F4BM is laminated by glass woven cloth, adhesive film, Teflon resin and polytetrafluoroethylene film, in accordance with scientific formula and strict technological process. This product has certain advantages over the F4B series in electrical performance (a wider range of dielectric constant, lower dielectric loss tangent, increased resistance, and more stable performance).

Dielectric Constant: 2.20 2.55 2.65 3.0

Dimension(mm): 300*250 380*350 440*550 500*500 460*610 600*500 840*840 840*1200 1500*1000

For special dimension,customized laminates is available.

Laminate thickness(mm): 0.25 0.5 0.8 1.0 1.5 2.0 3.0 4.0 5.0 6.0 8.0 10.0 12.0

Teflon high-frequency microwave PCB board

Teflon PCB is widely used to replace ordinary FR4 board because of its excellent characteristics such as good weather resistance, high insulation, high lubrication, non adhesion and non toxicity. Cu toate acestea, compared with ordinary FR4 board, Teflon PCB board is the smallest surface tension in solid materials, does not adhere to any substances, and has very small mechanical properties. Its friction coefficient is only 1 / 5 of that of polyethylene, This is an important feature of perfluorocarbon surface. În plus, due to the low intermolecular force of fluorine carbon chain, Teflon is not sticky, so it is not easy to adhere to the surface of the substrate in the production process of Teflon PCB.

Avantajul nostru

1. Quick respond,24 hours online service

2. No MOQ requirement

3. Diverse capabilities

4. Fast turnarounds available

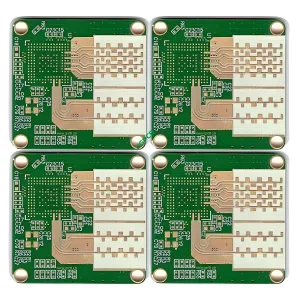

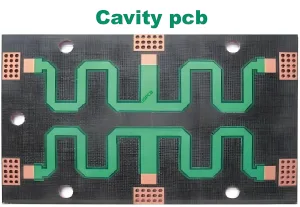

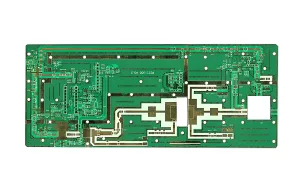

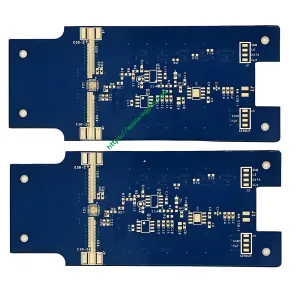

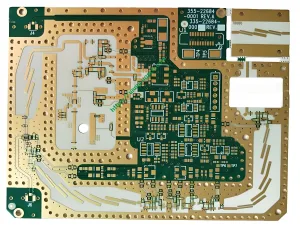

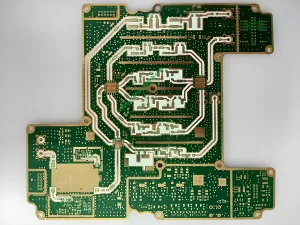

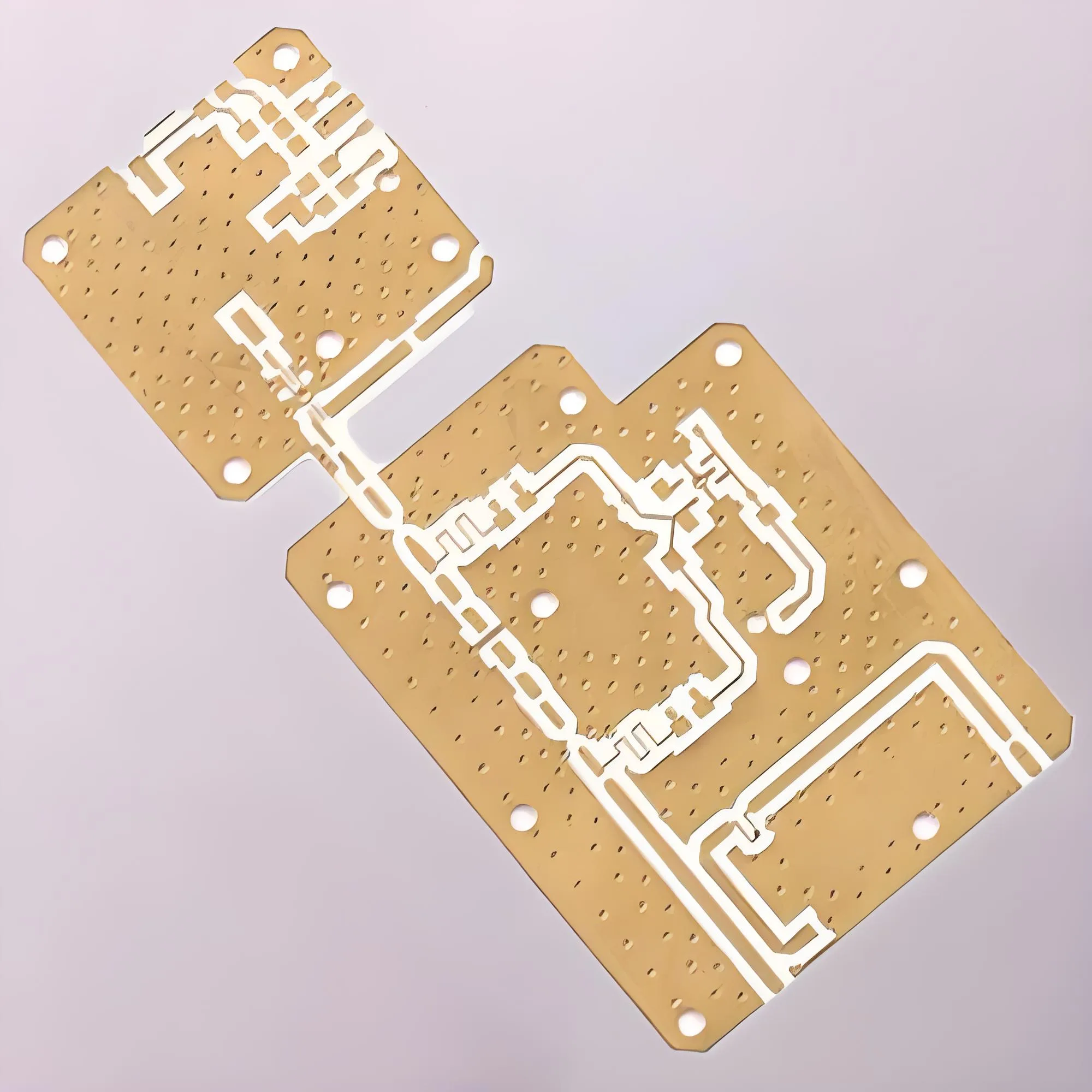

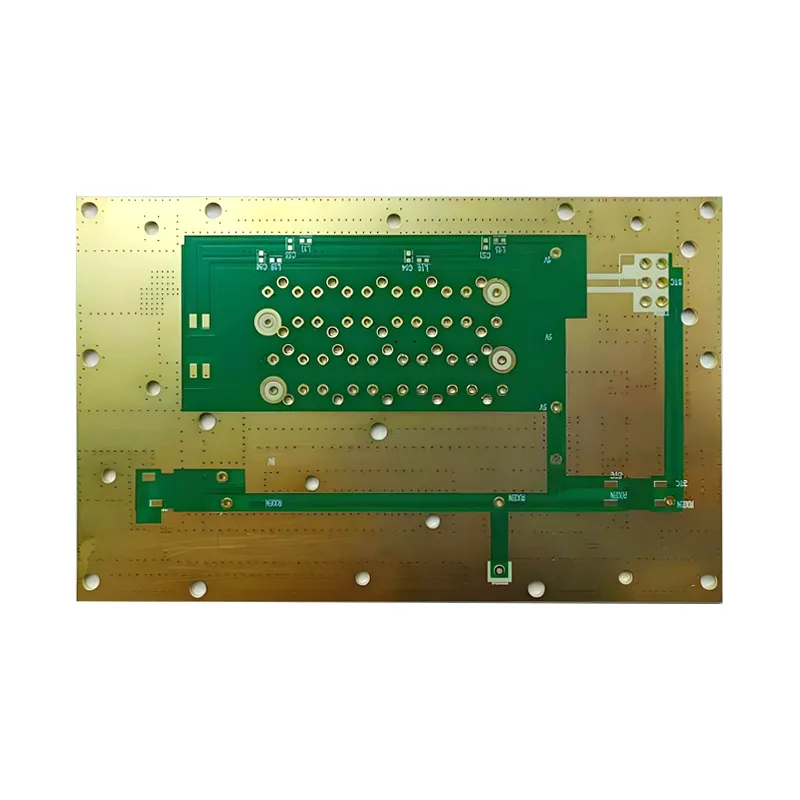

Real Project display:

The dielectric DK is wider, the tangential value of DF Angle is lower, the resistance value increases, and the performance is more stable.

RF/Microwave Teflon PCB application

Teflon PCB with radio frequency(PCB RF) are an increasingly used technique within the PCB industry.

–RF PCB with a high frequency with works above 100 MHZ.

–Microwave PCB with works above 2 GHz radio frequency.

Teflon PCB are used in different applications such as remote controls(Controale wireless)security,Smartphone -uri,sensors etc.

New technologies make more and more use of these RF applications.

This asks for a manufacturing according to high quality standards and choosing the right RF materials depending on the application.

It is important that one knows the properties of the various materials. Choosing the right material is perhaps the most critical decision in the production process of the Teflon PCB.

LOGO UGPCB

LOGO UGPCB