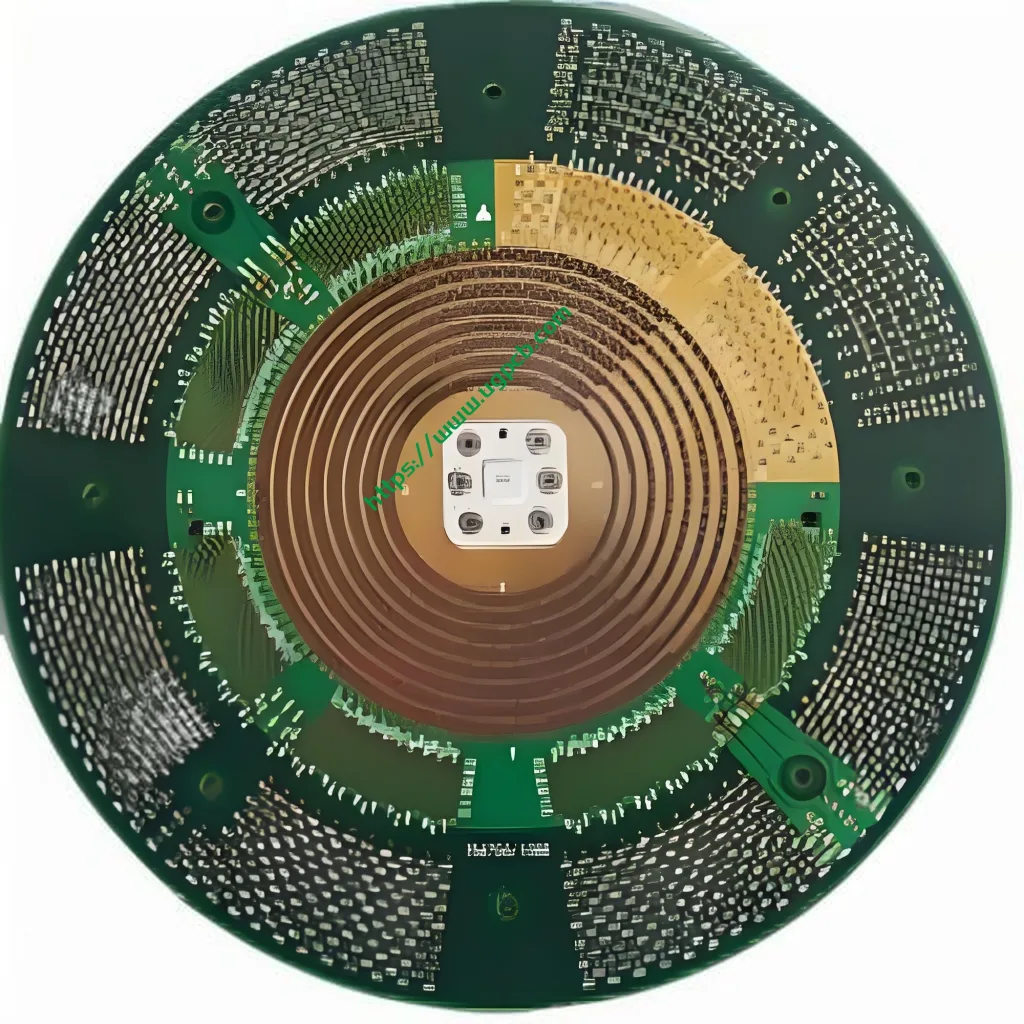

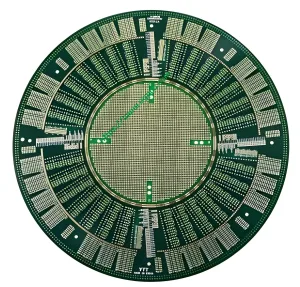

Introduction to the 44-Layer IC Probe Card PCB

The 44-Layer IC Probe Card PCB is a high-performance, multilayered printed circuit board designed for testing integrated circuit (IC) чипсы. This sophisticated product ensures accurate and reliable testing of semiconductor devices, making it an essential tool in the manufacturing and quality assurance processes of the electronics industry.

What is a 44-Layer IC Probe Card PCB?

A 44-Layer IC Probe Card PCB is a specialized type of PCB used for interfacing with integrated circuit chips during their testing phase. It features 44 слои проводящего материала, which provide ample pathways for electrical signals to travel, ensuring comprehensive testing coverage.

How Does It Work?

The probe card works by establishing physical and electrical contact with the microscopic pads on the IC chip. Each layer of the PCB is meticulously designed to align with specific test points on the chip, allowing for precise measurement of electrical parameters such as voltage, current, and resistance.

Applications and Purpose

Primarily, these probe cards are utilized in the semiconductor industry to test the functionality and performance of IC chips before they are packaged and soldered into electronic devices. They help in identifying any defects or malfunctions, ensuring only high-quality chips reach the market.

Types of IC Test PCBs

There are generally two main types of IC test PCBs:

- Probe Cards: Used for testing unpackaged chips directly from the wafer.

- Load Boards: Employed for testing packaged chips, often with more stringent impedance requirements due to higher speed interfaces.

Материальная композиция

The 44-Layer IC Probe Card PCB is made from TUC/TU872HF material, known for its excellent electrical properties and durability. The choice of material ensures that the PCB can withstand the rigorous demands of semiconductor testing.

Характеристики производительности

With a structure comprising 10mil, 12мил, and 14mil layers, this PCB offers enhanced signal integrity and reduced interference. The surface technology includes hard gold plating ranging from 3 к 15 Микроны, which provides superior conductivity and corrosion resistance. Special processes like metal cladding and depth control drilling further enhance its performance and reliability.

Структурные особенности

The PCB’s design includes varying layer thicknesses to accommodate different testing needs, with L1-L44 at 10mil, L1-L28 at 12mil, and L29-L44 at 14mil. This intricate layering allows for detailed and accurate testing of complex IC chips.

Производственный процесс

The manufacturing process of a 44-Layer IC Probe Card PCB involves several critical steps:

- Дизайн: Using specialized software to create the layout and ensure all test points are accurately placed.

- Выбор материала: Choosing high-quality materials like TUC/TU872HF for optimal performance.

- Наслоение: Stacking multiple layers of conductive material to form the PCB structure.

- Бурение: Creating holes for through-hole components and vias using depth control drilling techniques.

- Покрытие: Applying hard gold plating to ensure excellent conductivity and durability.

- Сборка: Mounting components and connectors onto the PCB.

- Тестирование: Conducting thorough tests to verify the PCB’s functionality and reliability.

Сценарии использования

These probe cards are predominantly used in:

- Semiconductor Fabs: For in-house testing of new IC designs.

- Quality Assurance Labs: To ensure compliance with industry standards.

- Research and Development Centers: For experimenting with new semiconductor technologies.

В заключение, the 44-Layer IC Probe Card PCB is an indispensable tool in the semiconductor industry, providing precise and reliable testing for IC chips. Its advanced design, high-quality materials, and rigorous production process make it a preferred choice for ensuring the highest standards of quality and performance in electronic devices.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ