Introduction to Resin Plug PCB

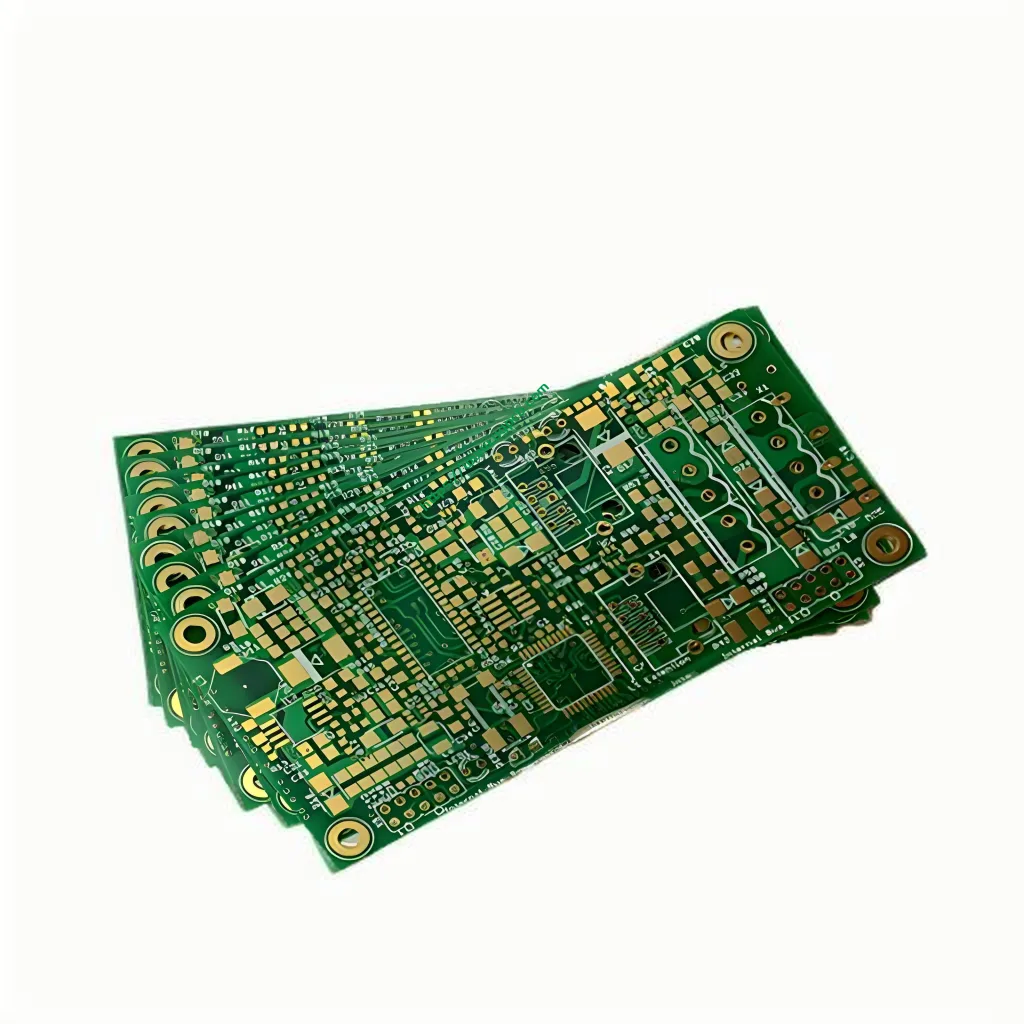

Обзор продукта

The Resin Plug PCB is a specialized type of printed circuit board (печатная плата) designed for high-performance electronic applications. It incorporates advanced resin plug technology, which enhances its mechanical stability and electrical performance. This PCB is particularly useful in digital products where space and reliability are critical factors.

Цель и приложение

The primary purpose of the Resin Plug PCB is to provide a robust and reliable platform for mounting and interconnecting electronic components. It is widely used in digital products such as smartphones, таблетки, ноутбуки, and other portable devices. Its compact design and high durability make it ideal for modern electronic applications that demand precision and efficiency.

Классификация

Resin Plug PCBs can be classified based on several criteria:

- Количество слоев: This PCB has 6 слои, allowing for complex circuit designs and efficient component placement.

- Материальная композиция: Made from S1141 material, known for its excellent thermal and mechanical properties.

- Обработка поверхности: Features immersion gold treatment, which offers superior conductivity and corrosion resistance.

Material and Construction

Материал

The Resin Plug PCB is made from S1141 material, chosen for its high strength and thermal stability. This ensures the PCB can withstand harsh operating conditions while maintaining its structural integrity.

Строительные детали

- Слои: Печатная плата состоит из 6 слои, providing ample space for intricate circuit designs.

- Готовая толщина: The PCB has a finished thickness of 1.2mm, optimizing both space efficiency and mechanical strength.

- Толщина меди: With copper layers of 1/0.5OZ, ПХБ обеспечивает эффективную электрическую проводимость.

- Цвет: Доступно в зеленом и белом, facilitating easy identification and aesthetic integration in various devices.

Характеристики производительности

- Special Technology: The use of resin plug technology enhances the PCB’s mechanical stability and electrical performance, making it suitable for high-reliability applications.

- Минимальная трассировка / Космос: The PCB supports fine pitch components with a minimum trace and space of BGA 3mil/3mil, enabling high-density component placement.

Производственный процесс

The manufacturing process of a Resin Plug PCB involves several key steps:

- Подготовка материала: Selecting and preparing the S1141 material for optimal performance.

- Наложение слоев: Stacking the 6 layers to achieve the desired thickness and functionality.

- Шаблон травления: Using chemical etching or laser cutting to create precise circuit patterns.

- Ламинирование: Сжатие слоев вместе под высоким давлением и температурой, чтобы сформировать единую единицу.

- Покрытие: Applying copper plating to ensure good electrical connectivity.

- Обработка поверхности: Treating the surface with immersion gold to enhance conductivity and corrosion resistance.

- Контроль качества: Проведение строгого тестирования, чтобы обеспечить соответствие печатной платы все характеристики производительности.

Ключевые функции и преимущества

- High Mechanical Stability: The resin plug technology provides exceptional mechanical stability, reducing the risk of component failure.

- Отличная электрическая производительность: The PCB’s design ensures consistent signal transmission and minimal interference.

- Долговечность: Made from high-strength materials, ensuring long-term reliability even under harsh conditions.

- Универсальность: Suitable for a wide range of digital products due to its adaptable design and material properties.

Сценарии использования

Resin Plug PCBs are essential in scenarios where high reliability and compact design are critical, такой как:

- Бытовая электроника: Enhancing the performance and durability of smartphones, таблетки, and laptops.

- Wearable Devices: Supporting the miniaturization and reliability of fitness trackers and smartwatches.

- Автомобильная электроника: Facilitating advanced driver-assistance systems and infotainment units in vehicles.

- Промышленные применения: Enabling precise control and monitoring in automation and control systems.

В заключение, the Resin Plug PCB represents a significant advancement in PCB technology, combining high mechanical stability with excellent electrical performance. Its robust construction and advanced features make it an ideal choice for modern digital products that require precision and reliability. Whether it’s enhancing the performance of consumer electronics or supporting critical automotive applications, this PCB stands out as a testament to innovation and engineering excellence.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ