Введение

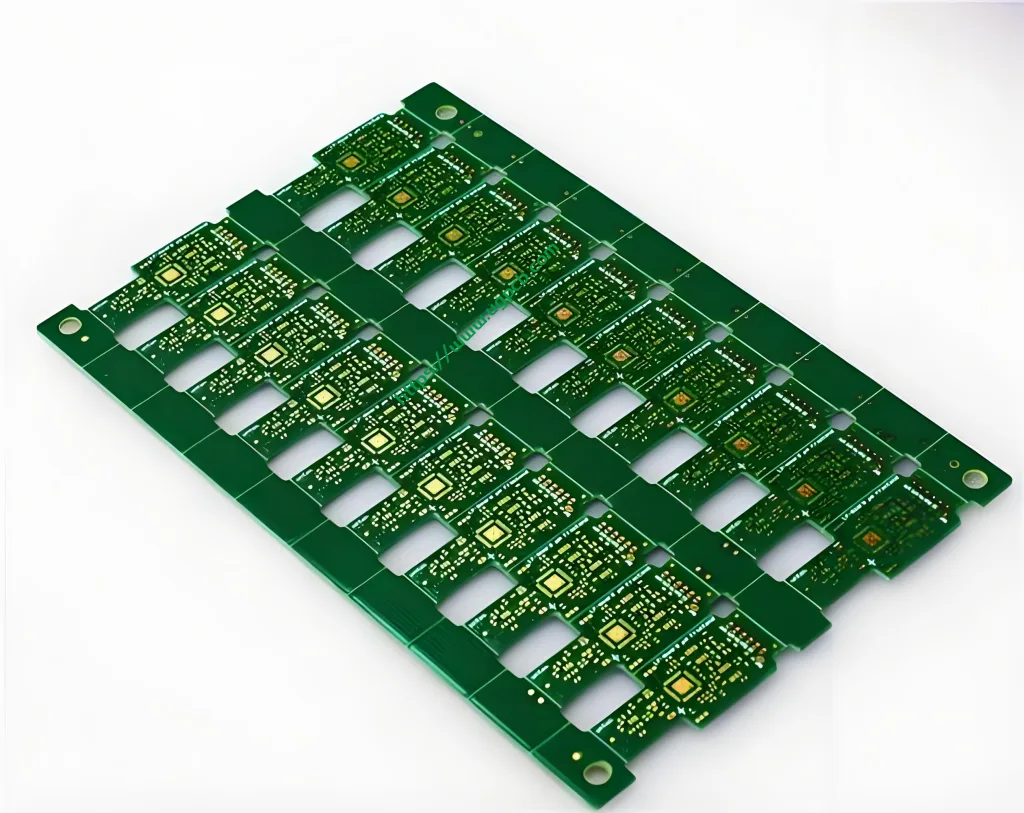

This is a mass production Double-side Printed Circuit Board (печатная плата) that is maturely produced by UGPCB. We provide customers with low-cost PCBs and allow customers’ products to occupy the market.

Types of Double-sided PCBs

Double-sided Printed Circuit Board (печатная плата) is a very important type of PCB. There are various types of double-sided PCBs available in the market, including double-sided circuit board metal base PCB, Hi-Tg heavy copper foil PCB, flat winding High-frequency double-sided PCB, высокочастотная печатная плата, hybrid dielectric base high-frequency double-sided PCB, и т. д.. These PCBs are suitable for a wide range of high-tech industries such as telecommunications, источник питания, компьютеры, промышленный контроль, digital products, scientific and educational equipment, Медицинское оборудование, Автомобили, аэрокосмический, и т. д..

Composition and Use

Double-sided Printed Circuit Board (печатная плата) is usually made of epoxy glass cloth copper clad board. It is mainly used for communication electronic equipment, advanced instruments, and electronic computers with high performance requirements.

Производственный процесс

The production process of Double-sided Printed Circuit Board (печатная плата) is generally divided into process wire method, hole blocking method, masking method, and pattern plating-etching method. The process flow of the pattern plating-etching method is commonly used.

Proofing and Finishing Processes

Double-sided Printed Circuit Board (печатная плата) proofing is commonly done using craftsmanship. Кроме того, processes such as the rosin process, OSP process, gold plating process, immersion gold and silver plating processes are also applicable.

Specific Finishing Processes

Spray tin process: This offers a good appearance with a silver-white pad that is easy to tin and solder, and is cost-effective.

Sikkim process: This ensures stable quality and is usually used in cases involving bonding IC.

Circuit Layout

The difference between a double-sided Printed Circuit Board (печатная плата) and a single-sided Printed Circuit Board (печатная плата) is that the circuit of the single-sided PCB is only on one side of the PCB, while the double-sided PCB has circuits on both sides, connected through vias in the middle.

Production Parameters

The production of double-sided Printed Circuit Board (печатная плата) differs from that of single-sided Printed Circuit Board (печатная плата). In addition to the production process, there is an additional copper sinking process, which is the process of circuit conduction on both sides of the PCB.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ