Введение в печатную плату разъема типа C

ПХБ разъема типа C-это расширенный электронный компонент, предназначенный для высокоскоростных данных и передачи питания. Это руководство содержит полный обзор продукта, включая его определение, Проектные требования, рабочие принципы, Использование, классификации, материалы, производительность, структура, функции, Процесс производства, и типичные сценарии применения.

Определение

Печата разъема типа C (Печатная плата) является специализированным монтажная плата that incorporates a USB Type-C connector. Он предназначен для поддержки высокоскоростной передачи данных и доставки питания, сделать его идеальным для современных электронных устройств.

Требования к дизайну

Конструкция печатной платы разъема типа C должна придерживаться определенных стандартов, чтобы обеспечить оптимальную производительность и надежность. Ключевые требования к проектированию включают:

Высокоскоростная передача данных

Поддерживает USB 3.1 Генерал 2 или более высокие стандарты для быстрой скорости передачи данных.

Доставка энергии

Способен обрабатывать до 100 Вт доставки энергии, Подходит для зарядных и питательных устройств.

Минимальное след/пространство

Обеспечивает то, что компоненты тонкого шага могут быть точно размещены с минимальной трассой/пространством 3 мили/3 мили.

Точные допуски

Поддерживает строгие требования к допусков для наброска и PSR (Выберите и помещайте надежность).

Принцип работы

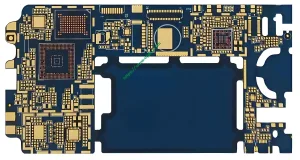

ПХБ разъема типа C работает на основе принципов электрической проводимости и целостности сигнала. It utilizes copper traces embedded in a high TG FR4 substrate to transmit signals between the Type-C connector and other electronic components on the board. Погрузчика по погружению золота и поверхности OSP повышают проводимость и защиту от окисления.

Использование

ПХД разъема типа C используются в различных приложениях, где высокоскоростная передача данных и доставка мощности важны. Общее использование включает:

Передача данных

Облегчает быструю и эффективную передачу данных между такими устройствами, как ноутбуки, смартфоны, и внешние устройства хранения.

Источник питания

Обеспечивает надежную доставку питания для зарядки батарей и питания электронных устройств.

Подключение к устройству

Обеспечивает связь между различными устройствами, Улучшение функциональности и универсальности электронных систем.

Классификации

ПХБ разъема типа C можно классифицировать на основе нескольких критериев:

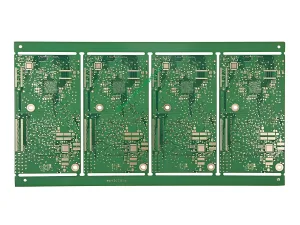

По количеству слоев

Многослойные печатные платы, такие как 6-слойный HDI (Взаимодействие высокой плотности) Печата упомянута.

Материалом

Построенный из высокого материала TG FR4 для повышенной термостабильности.

По поверхности обработка

Особенности погружения золота и OSP (Органическая припаяя консервант) Поверхностные обработки для улучшения проводимости и долговечности.

Материалы

Основные материалы, используемые при построении ПХБ разъема типа C, включают:

Высокий TG FR4

Пламя-сражающий стеклянный эпоксидный ламинат материал, известный своей высокой тепловой стабильностью и механической прочностью.

Медь

Используется для проводящих следов, с стандартной толщиной 1 унции.

Зеленый/белый цвет (Пса: Taiyo Ink)

Цвет печатной платы, достигнуто с использованием чернил Taiyo для последовательных и ярких результатов.

Производительность

Производительность ПХБ соединителя типа C характеризуется:

Высокая целостность сигнала

Обеспечивает минимальную потерю качества сигнала на больших расстояниях и высоких частотах.

Долговечность

Устойчивые к факторам окружающей среды, такие как изменение температуры и влажность.

Надежность

Разработан для выдержания повторных соединений и разъединений без разложения.

Структура

Структура печатной платы разъема типа C обычно включает:

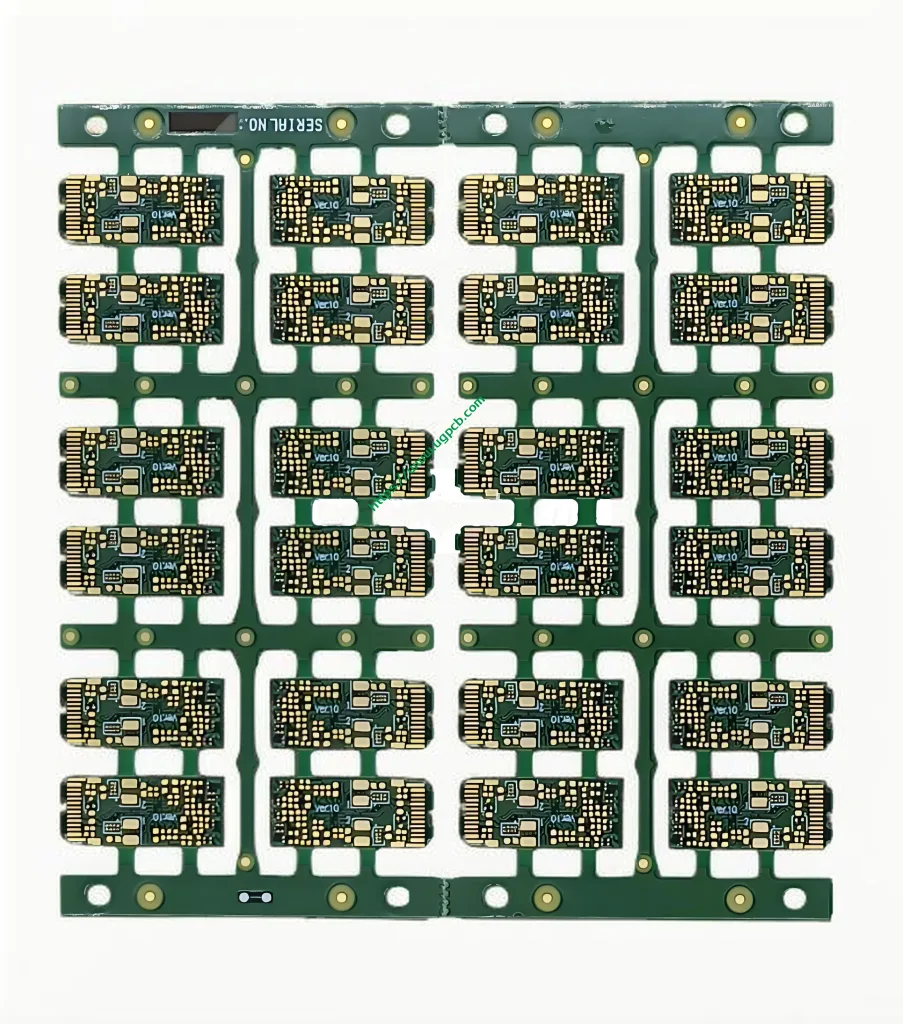

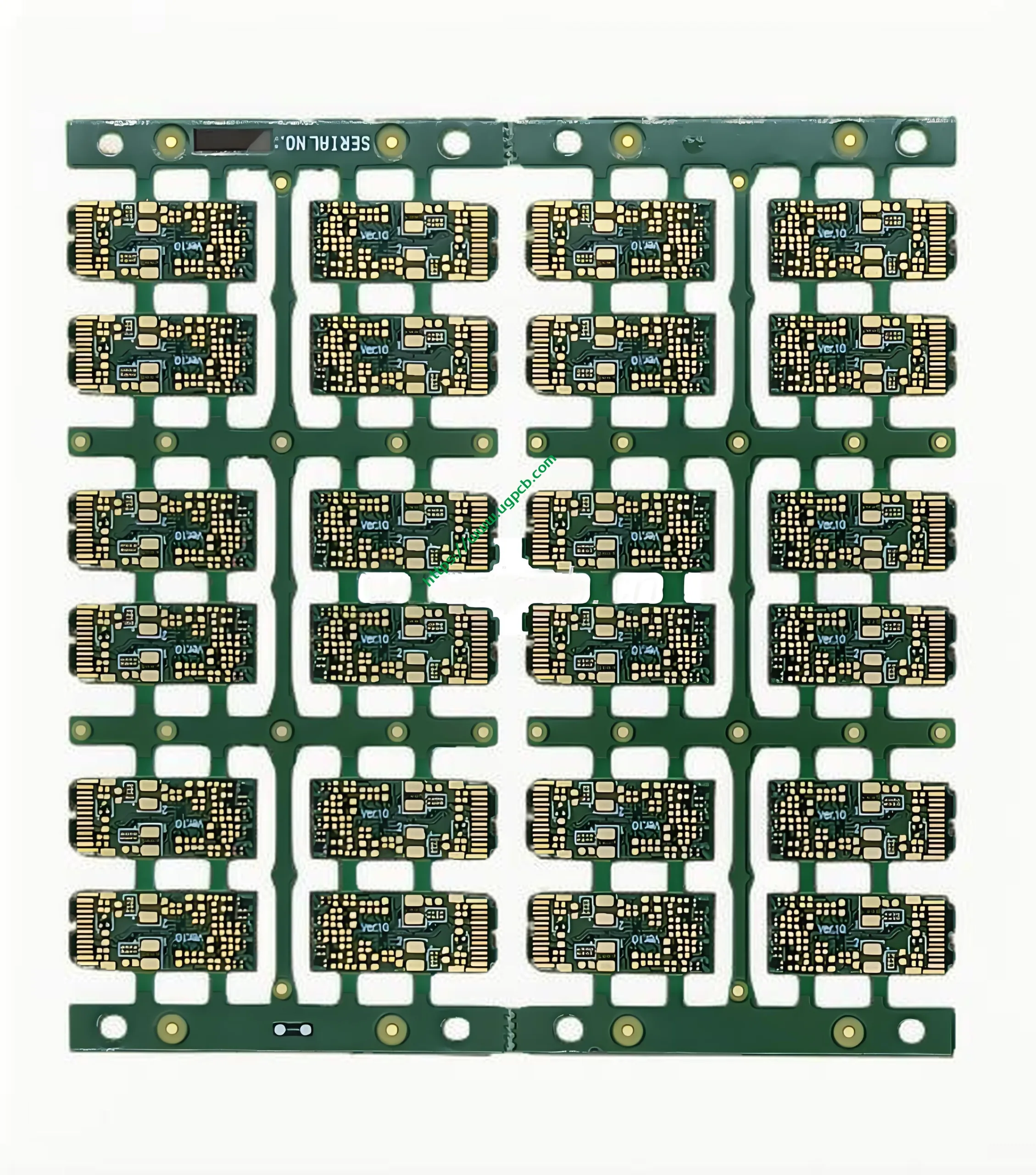

Многослойный дизайн

A 6-layer HDI печатная плата with 2+N+2 layer configuration for complex circuitry.

Компоненты прекрасного шага

Позволяет интегрировать компоненты тонкого шага с минимальным размером отверстия 0,2 мм для механических отверстий и 0,1 мм для лазерных отверстий.

Расширенная поверхностная обработка

Покрытие погружения золота и OSP повышают проводимость и защиту от коррозии.

Функции

Ключевые особенности печатных плат соединителя типа C включают:

Высокоскоростные данные и передача мощности

Поддерживает USB 3.1 Генерал 2 или более высокие стандарты для быстрой передачи данных и до 100 Вт..

Компактный дизайн

Тонкий профиль с готовой толщиной 0,8 мм, Подходит для тонких и гладких конструкций устройств.

Надежное строительство

Сделано из высокого материала TG FR4 для повышения долговечности и термической стабильности.

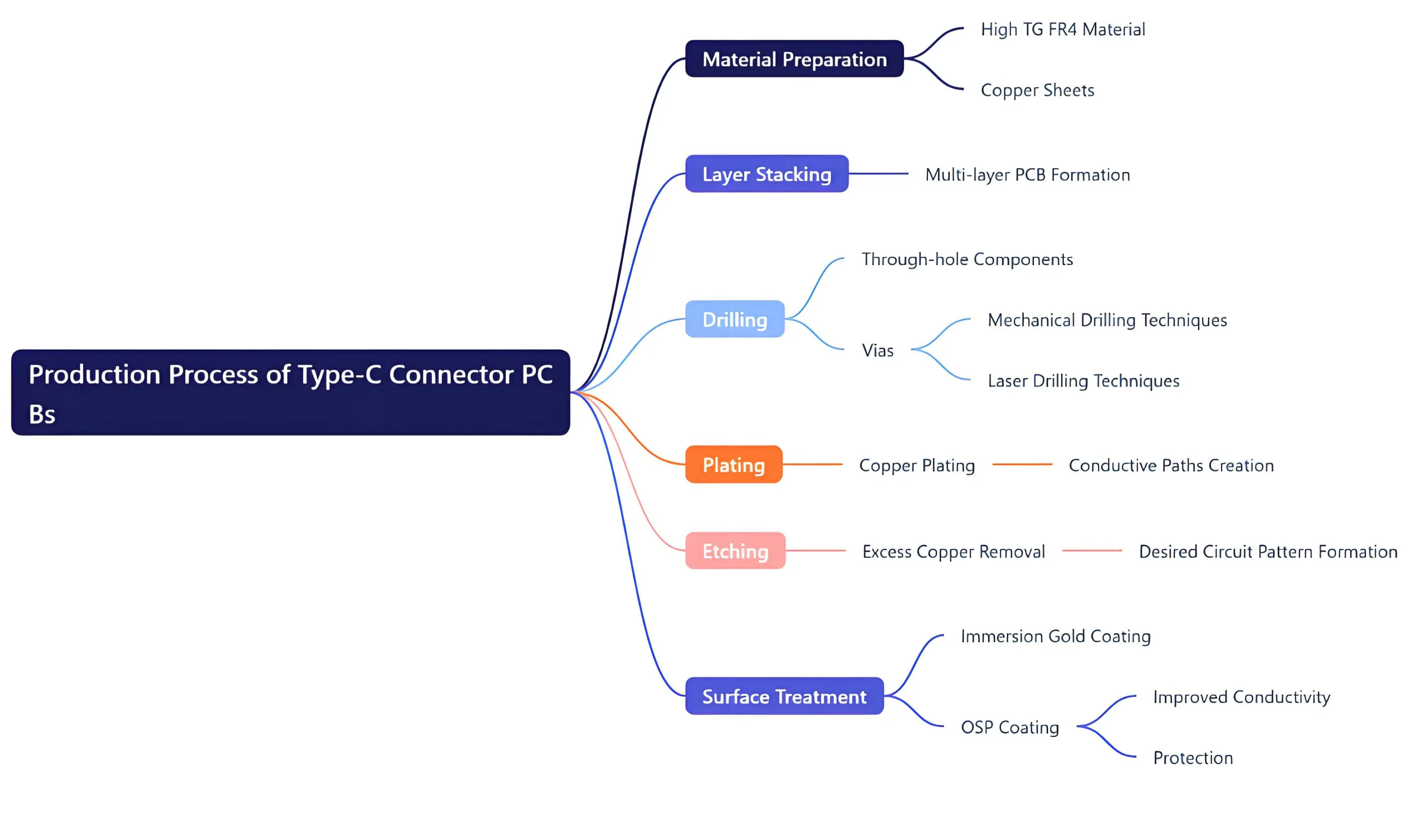

Производственный процесс

Производство ПХБ разъема типа C включает в себя несколько этапов:

Подготовка материала

Выбор материала с высоким TG FR4 и медными листами.

Наложение слоев

Упаковка нескольких слоев для формирования многослойной печатной платы.

Бурение

Создание отверстий для компонентов и варксеров с использованием механического и лазерного бурения.

Покрытие

Применение медного покрытия для создания проводящих путей.

Офорт

Удаление избыточной меди для формирования желаемой схемы цепи.

Обработка поверхности

Применение погружений золота и покрытий OSP для улучшения проводимости и защиты.

Типичные сценарии применения

ПХБ разъема типа C широко используются в различных приложениях, включая:

Бытовая электроника

Смартфоны, таблетки, ноутбуки, и другие портативные устройства.

Автомобильная промышленность

Развлекательные системы и зарядные решения в автомобильных автомобилях.

Промышленное оборудование

Управляющие панели и устройства связи, требующие надежного подключения.

Понимая эти аспекты, Вы можете оценить универсальность и важность ПХБ соединителей типа C в современном электронном дизайне.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ