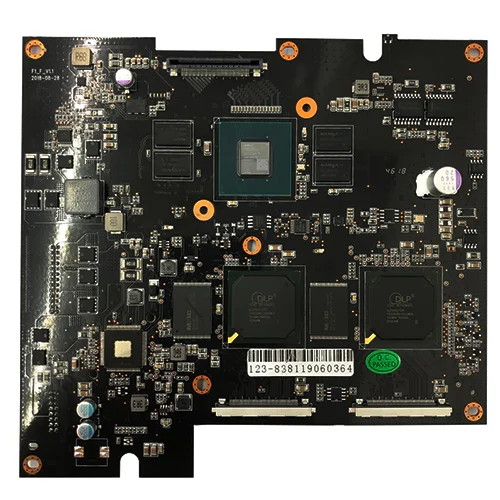

Printed Circuit BoardAssembly Services

Printed circuit board Assembly(печатная плата) Услуги: Файл печатной платы & Bom pls отправить на sales@ugpcb.com ( Быстрая цитата PCBA)

PCBA - это процесс, который требует знаний не только компонентов и сборки печатной платы, но и дизайна печатной платы, Изготовление печатной платы и хорошее понимание конечного продукта. PCBA - это всего лишь одна часть головоломки для доставки идеального продукта в первый раз.

UGPCB Соберите вашу печатную плату с помощью электронных компонентов в SMT ( технология поверхностного монтажа), В обычном процессе пайки волны (через технологию дыры), в комбинации обоих процессов, новый процесс THR (через отверстие). Все процессы пайки могут быть выполнены как с припоями без свинца, так и с припоями, содержащими свинец. Мы были бы рады позаботиться о полных материалах для вас.

UGPCB предлагает следующие печатные платы в сборе(печатная плата) Услуги:

А.,24-Служба сборки часовой платы

Б.,Частичная сборка ключей,Сборка партии

Служба подготовки и документации списка.

D. Кост-эффективные закупки материала за счет покупки синергии в UGPCB

E.automated Optical Inspection (АОИ) SMD Assemblies

F.SMD Сборка компонентов из тонких питков (например. БГА, QFN, ММФ, Разъем микроспид)

Компоненты G.Handling, восприимчивые к влаге (чувствительный уровень влаги ≥ 3)

H.ROHS COMPARINT ASSEMBLY FRED LEAD

И.

J. Производство и проверка сборок в соответствии с классом IPC-A610 2

k. SMD Assembly EquipmentS

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ