Многослойный обзор средств на машине PCB

Многослойная гибка автомобиля PCB-сложная и высокопроизводительная печатная плата разработано специально для использования в автомобильных приложениях. Он объединяет передовые технологии с строгими стандартами качества, чтобы обеспечить оптимальную производительность и надежность в транспортных средствах. Эта материальная плата играет решающую роль в функциональности современных автомобилей, Интеграция различных электронных компоненты и системы плавно.

Требования к определению и проектированию

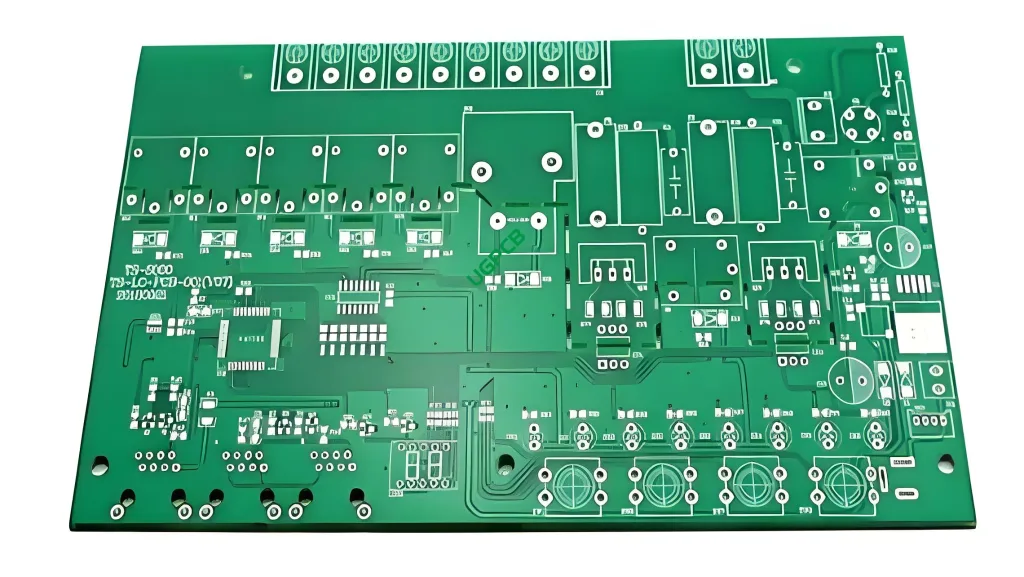

Многослойная трапальная плата PCB определяется его многослойной структурой, который допускает сложные схемы и высокую плотность компонентов. Требования к проектированию для такой материнской платы строги, Обеспечение совместимости с автомобильной средой. Ключевые аспекты дизайна включают ширину трассировки и расстояние, толщина меди, и обработка поверхности, Все адаптировано для удовлетворения требований электроники транспортных средств.

Принцип работы

Принцип работы многослойной традиционной платы транспортного средства включает в себя эффективную проводимость электрических сигналов через несколько слоев печатной платы. Сигналы перемещаются по медным следам на разных слоях, взаимосвязанный VIAS и выселенные сквозные отверстия. Эта архитектура позволяет материнской плате обрабатывать высокоскоростную передачу данных и сложные функции, необходимые в современных транспортных средствах.

Приложения и классификация

Основное применение многослойной традиционной панели автомобильной платы в автомобильной промышленности находится в автомобильной промышленности, где он служит центральным центром для различных электронных систем в автомобиле. Эти материальные доски классифицируются на основе количества слоев, материальная композиция, и конкретные особенности, такие как OSP (Органо -припаяность консервантов) обработка поверхности, который повышает припадение и защищает от окисления.

Материал и производительность

Построен из материала KB FR-4, Эти материальные доски обеспечивают отличную термостабильность и механическую прочность, необходимо для автомобильных приложений. Зеленый или белый цветовой кодирование помогает в визуальном осмотре во время производства. С законченной толщиной 1,2 мм и толщиной меди 1 унции, Они обеспечивают надежную платформу для надежных производительности в требовательных условиях.

Структура и особенности

Структура многослойной традиционной платы за печатную плату обычно включает в себя шесть слоев, Каждый служит конкретной цели в процессе передачи сигнала. Его ключевая особенность - приверженность сертификации TS16949, что гарантирует, что продукт соответствует стандартам высочайшего качества и надежности для автомобильных приложений. Кроме того, Обработка поверхности OSP повышает долговечность и припаяность на финике.

Производственный процесс

Производственный процесс многослойной традиционной панели автомобилей PCB включает в себя несколько этапов, включая материал подготовка, нажатие слоя, бурение, Медное покрытие, и окончательные процессы отделки, такие как приложение OSP. Усовершенствованные методы производства обеспечивают точный контроль над каждым аспектом, от ширины трассировки до диаметра отверстия, гарантирование высококачественных выходов, подходящих для автомобильного использования.

Сценарии использования

Многослойные платы за печатную плату используются в различных автомобильных системах, в том числе подразделения управления двигателями, информационно -развлекательные системы, Расширенные системы помощи водителю (Адас), и еще. Они являются интегральными компонентами в транспортных средствах, позволяет производителям интегрировать сложные электронные функции, сохраняя при этом высокие стандарты безопасности и производительности.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ