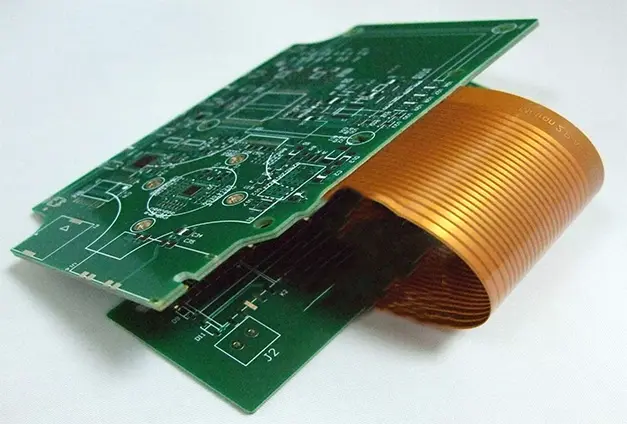

Flexible circuit board assembly were originally designed to replace traditional wire harnesses. Today’s trends including IoT, connectivity, mobility, wearables, miniaturization and more are driving rapid growth in the demand and use of flexible printed circuits in most industries. A flexible circuit in its purest form is a large number of conductors sandwiched between very thin layers of dielectric film.

From the simple to the most complex, the versatility of flexible printed circuit boards is unmatched.

As a connection device, the main advantages of flex circuits compared to traditional wiring and rigid circuit boards include:

Reduce wiring errors

Elimination of mechanical connectors

Unmatched pcb design flexibility

Higher circuit density

Greater operating temperature range

Stronger signal quality

Improved reliability and impedance control

Reduced size and weight

Flexible printed circuits have many benefits, включая:

Reduce assembly errors – Compared to hand-crafted wiring harnesses, flex circuits eliminate human error through precise design and automated production. Circuits are routed only to those points required by the schematic, netlist, or gerber file.

Reduced assembly time and cost – Flex circuits require less labor during assembly and reduce production errors. Flexible circuits have an inherent ability to integrate form, fit and function. Flex circuits eliminate the high cost of routing, wrapping and soldering wires. Wiring errors are eliminated, thus reducing manufacturing costs. Assembly time and cost can be reduced, whether for low-volume production of complex circuits or high-volume production of simple circuits.

Design freedom – Unlike rigid boards, flex circuits are not limited to two dimensions. Because they are as flexible as wire or ribbon cables, the flexible PCB design options are endless. At Flexible Circuit Technologies, we pride ourselves on tackling the most complex design challenges. Flexible circuits can be designed to meet highly complex and unimaginable configurations while being able to operate in the harshest environments. A flex circuit design may require any of the following:

Highly complex configuration

Withstands harsh shock and vibration operating environments

Complex interconnects

Shield

Однослойный, multi-layer and rigid/flexible capabilities

Surface mount equipment

Harness conversion to flex reduces wiring errors for manual connections and reduces assembly time

Flexibility during installation – Flex circuits allow the use of a third dimension as they can be interconnected between two or more planes as they are formed. Поэтому, they solve the space and weight problems that rigid boards cannot match. Flexible circuits can be operated multiple times during installation and repair without electronic failure.

High Density Applications – Flex circuits allow extremely narrow lines and spaces to give way to high density device clusters. Dense device counts and lighter conductors can be designed into products to make room for other product features.

Improved Airflow – Thanks to its streamlined design, flex circuits allow cooling air to flow through electronic applications.

Increased heat dissipation – Due to the large surface area-to-volume ratio of copper traces and the ultra-thin dielectric overlay, heat generated in the traces is more easily dissipated. Кроме того, the thinner design of the flex circuit allows heat to be dissipated from both sides of the circuit.

Improve system reliability – В прошлом, most circuit failures occurred at the point of interconnection. Flexible circuits can be designed to reduce interconnections, thereby increasing the reliability of the circuit.

Reliability and Durability – A properly designed dynamic flex circuit can move and bend over a million times without failure.

Repeatable Wiring – Our circuits are made from exact replicas of artwork for superior manufacturing consistency. Etched circuits replace the solder and hand routing connections of rigid boards, completely eliminating routing errors.

Simplified Circuit Geometry – Flexible circuit technology places surface mount electronics directly on the circuit, simplifying the entire production process. Customers can obtain flex circuits fully assembled with all components.

Package size and weight reduction – Thicker dielectric cores in rigid boards create more weight and take up more space. Flexible circuits contain the thinnest dielectric substrates available. The thinness allows for a more streamlined design without the need for bulky rigid boards. The flexibility allows overall package size reduction. In addition to reducing package size, package weight is also reduced. With the ever-increasing demands of the electronics industry, reductions in weight and volume make flex circuits an attractive interconnect solution.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ