Материал

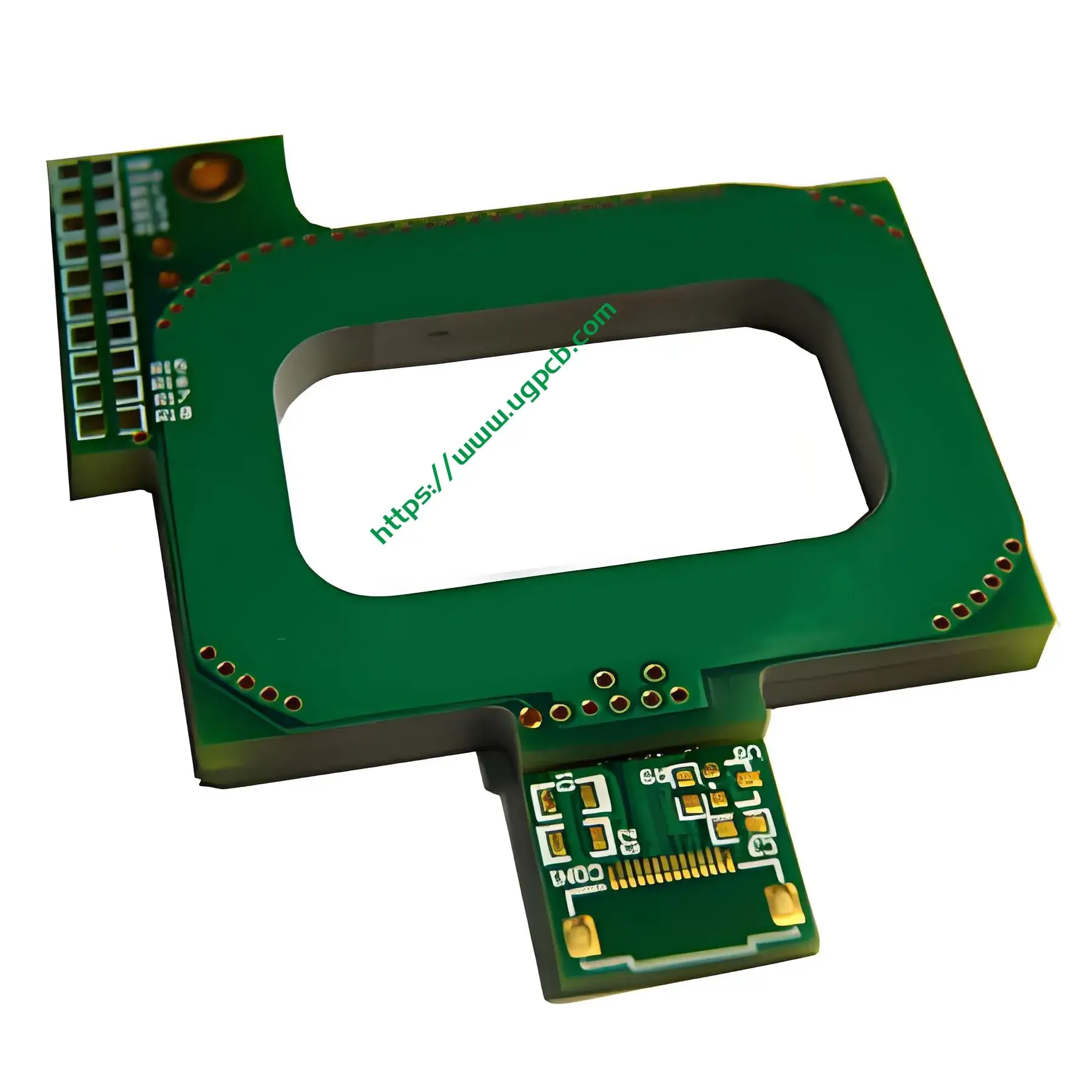

The Step slot PCB board is manufactured using FR-4 TG170 material. FR-4 stands for Flame Retardant 4, a grade of epoxy resin-based laminate that is widely used in the production of printed circuit boards (печатные платы) due to its excellent electrical properties, механическая прочность, и термостойкость. The TG170 indicates a glass transition temperature of 170°C, ensuring the board maintains its structural integrity and electrical performance even under high-temperature conditions.

Производительность

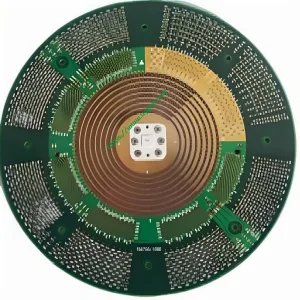

This PCB board features a 4-layer design, which allows for more complex circuitry and higher component density. The copper thickness of 1OZ (ounce per square foot, approximately 35 Микроны) provides good conductivity and current carrying capacity. With a finished thickness of 2.0mm, the board offers robust physical durability. The immersion gold surface treatment enhances the solderability of the board, reducing the risk of corrosion and improving reliability in electronic assemblies.

Характеристики

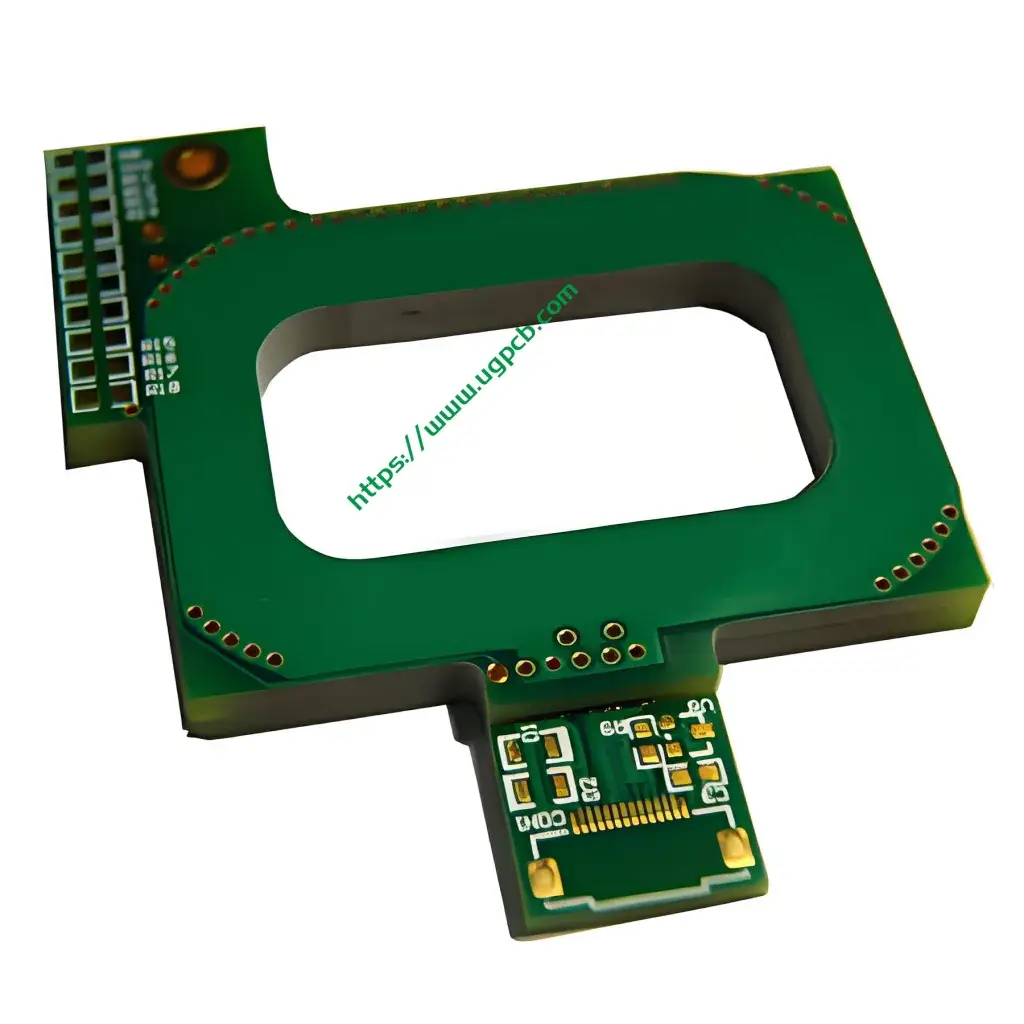

The Step slot PCB board is distinguished by its unique step slot design. This special process creates a stepped or tiered opening in the board, allowing for more flexible routing of traces and components, especially in compact designs. The trace/space of 6mil/6mil (0.152mm/0.152mm) ensures precise and reliable electrical connections, while the minimum hole size of 0.3mm (12мил) facilitates the use of small components and tight packaging.

Production Flow

The production of Step slot PCB boards involves several critical steps:

- Подготовка материала: FR-4 TG170 laminate is cut to size and prepared for processing.

- Медная ламинирование: Thin sheets of copper are bonded to the laminate to form the conductive layers.

- Бурение: Precision drilling creates the vias and component holes, including the special step slot features.

- Покрытие: The holes are plated with copper and, subsequently, immersion gold to prepare them for soldering.

- Паттерн схемы: Using photolithography, the copper is etched away to form the desired circuit patterns.

- Soldermask Application: A protective layer of soldermask is applied to protect the circuitry and provide a smooth surface for component placement.

- Surface Finish: The immersion gold treatment is applied to enhance solderability.

- Окончательный осмотр и тестирование: Each board undergoes rigorous inspection and testing to ensure it meets quality standards.

Сценарии приложения

The Step slot PCB board is ideally suited for use in module PCB boards. Его компактный дизайн, high component density, and enhanced electrical performance make it an excellent choice for applications requiring intricate circuitry and reliable performance. Примеры включают:

- Telecommunication Equipment: High-density interconnect modules for signal processing and transmission.

- Computer Hardware: Motherboards, видеокарты, and other components requiring complex circuitry.

- Industrial Automation: Control systems and sensors that require reliable and compact PCB solutions.

- Бытовая электроника: Смартфоны, таблетки, and other devices where space is a premium and high performance is essential.

В итоге, the Step slot PCB board combines advanced materials, precise manufacturing processes, and unique design features to meet the demands of high-performance electronic applications.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ