Таконическая печатная плата: What does it mean?

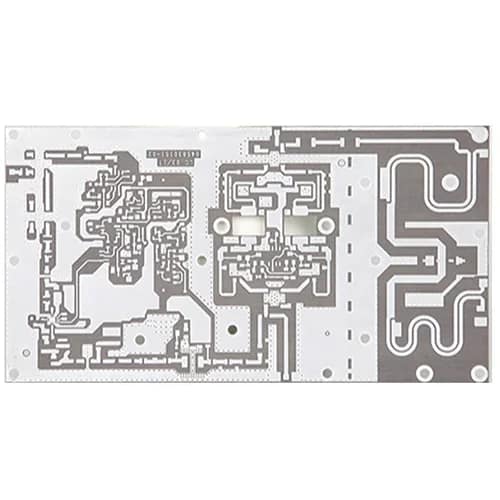

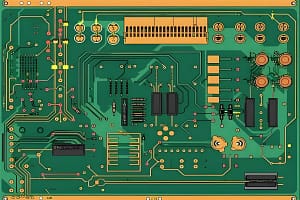

Taconic PCB is a printed circuit board manufactured using Taconic PCB materials. These materials are ceramic-filled polytetrafluoroethylene and glass fiber reinforced materials. These boards are suitable for RF applications in the communications and aerospace industries.

This printed circuit board has low dielectric loss and electrical signal loss, making it ideal for a variety of applications. The board is designed to meet the growing demands of the electronics world. Taconic PCB is available in a variety of dielectric constant values.

Taconic is a well-known brand in the field of RF laminates. It provides printed circuit boards for manufacturing high-performance digital boards, multi-layer RF, и другие электронные устройства. Taconic laminates can be milled, plated, and cut using standard methods.

What is the difference between Taconic PCB and Isola PCB?

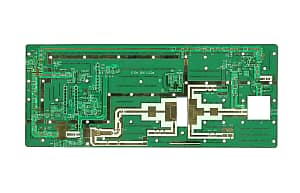

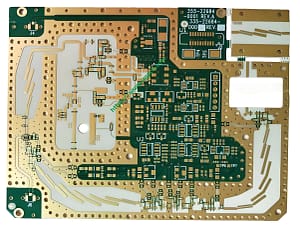

Many people wonder what the difference is between Taconic and Isola PCB. These two types of printed circuit boards have similar advantages, but they are different from each other. Taconic PCB uses ceramic-filled PTFE or glass-reinforced PTFE PCB, which makes it thermally and electrically stable.

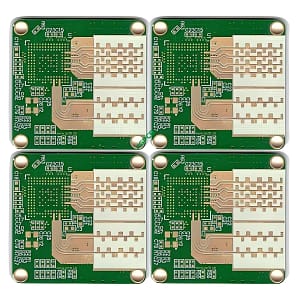

Taconic panels utilize thermoplastic prepregs and thermoset materials to meet the needs of high-performance panels. These boards are ideal for microwave or RF designs.

Тем временем, Isola PCBs are manufactured using copper clad laminates and dielectric prepregs. These laminates have a resin composition that meets the needs of high-performance applications. Isola PCBs have excellent mechanical, тепло, и электрические свойства. These properties provide materials that exceed FR-4.

Taconic and Isola PCBs are designed for high-speed and high-performance applications, but these boards use different materials in production.

Advantages of Taconic PCBs

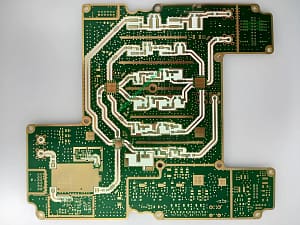

Бюджетный: When making such boards, low cost is a requirement. It is always an affordable option for engineers. This ceramic-filled laminate offers great value for money.

Низкие диэлектрические потери: Low dielectric loss laminates are ideal for RF and microwave applications. The dielectric loss of Taconic is very low. The low dielectric loss of this material is a result of the dielectric constant of this material.

Low Electrical Signal Loss: This is a big advantage of these boards. Taconic laminates have low dielectric signal losses due to the materials used in their manufacturing.

Wide range of dielectric constants: Taconic PCBs offer a wide range of dielectric constants. This makes it ideal for a variety of applications.

Low dissipation factor: This circuit board has a low dissipation factor and is a great insulating material. A low dissipation factor indicates an effective insulator system.

Отличная стабильность размеров: Taconic PCBs retain their original dimensions even when exposed to heat. Engineers use this board for applications where it may be exposed to varying temperatures.

Низкое поглощение влаги: This board has low moisture absorption. Следовательно, it can be used in humid environments. Moisture is not good for the durability of the PCB, so PCBs with low moisture absorption are an ideal choice.

Factors to Consider in Hybrid Manufacturing of Taconic PCBs

There are a few factors that need to be considered during the hybrid manufacturing of Taconic PCBs, то есть, Taconic rf 35 pcb.

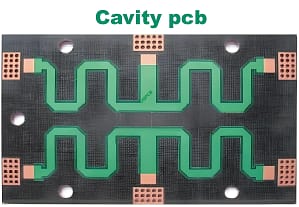

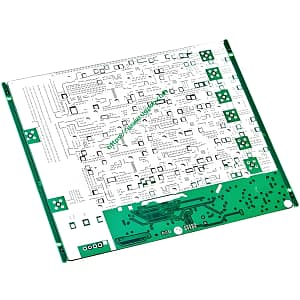

Drilling parameters: Drilling parameters are a critical factor to consider as it determines the correct drill hole formation. The feed and speed of the drill bit are determined by the stacked materials. In a hybrid manufacturing process, the speed and feed need to be adjusted. Например, some components dissipate a lot of heat, which can cause deformation.

Compatible materials: The materials used in the hybrid stack should be matched to the lamination cycle. Some materials require higher temperatures and pressures during the lamination process. You should always check the material’s data sheet to confirm the material’s purpose before using it in your design.

Prepare the hole wall: After drilling the hole, the next step is to prepare the hole wall. For each general group, there may be process instructions. You must improve the process for each material to obtain overall reliability.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ