Роджерс (Арлон) Серия AD: Advanced Microwave High-Frequency PCB Materials

Introduction to Rogers (Арлон) Серия AD

The Rogers (Арлон) AD250C, AD255C, и AD260A представляют третье поколение коммерческих ламинатов для микроволновой и радиочастотной связи.. These materials are distinguished by their low dielectric constants, cost-effectiveness, and exceptional low-loss characteristics, making them highly suitable for modern telecommunications infrastructure.

Cost-Effective Combination for Superior Performance

Роджерс (Арлон) AD250C, AD255C, and AD260A microwave high-frequency PCB materials leverage a cost-efficient blend of composite chemistry and architecture. This combination delivers an unmatched price-performance ratio, essential for today’s demanding telecommunications applications.

Unmatched Thermal and Electrical Properties

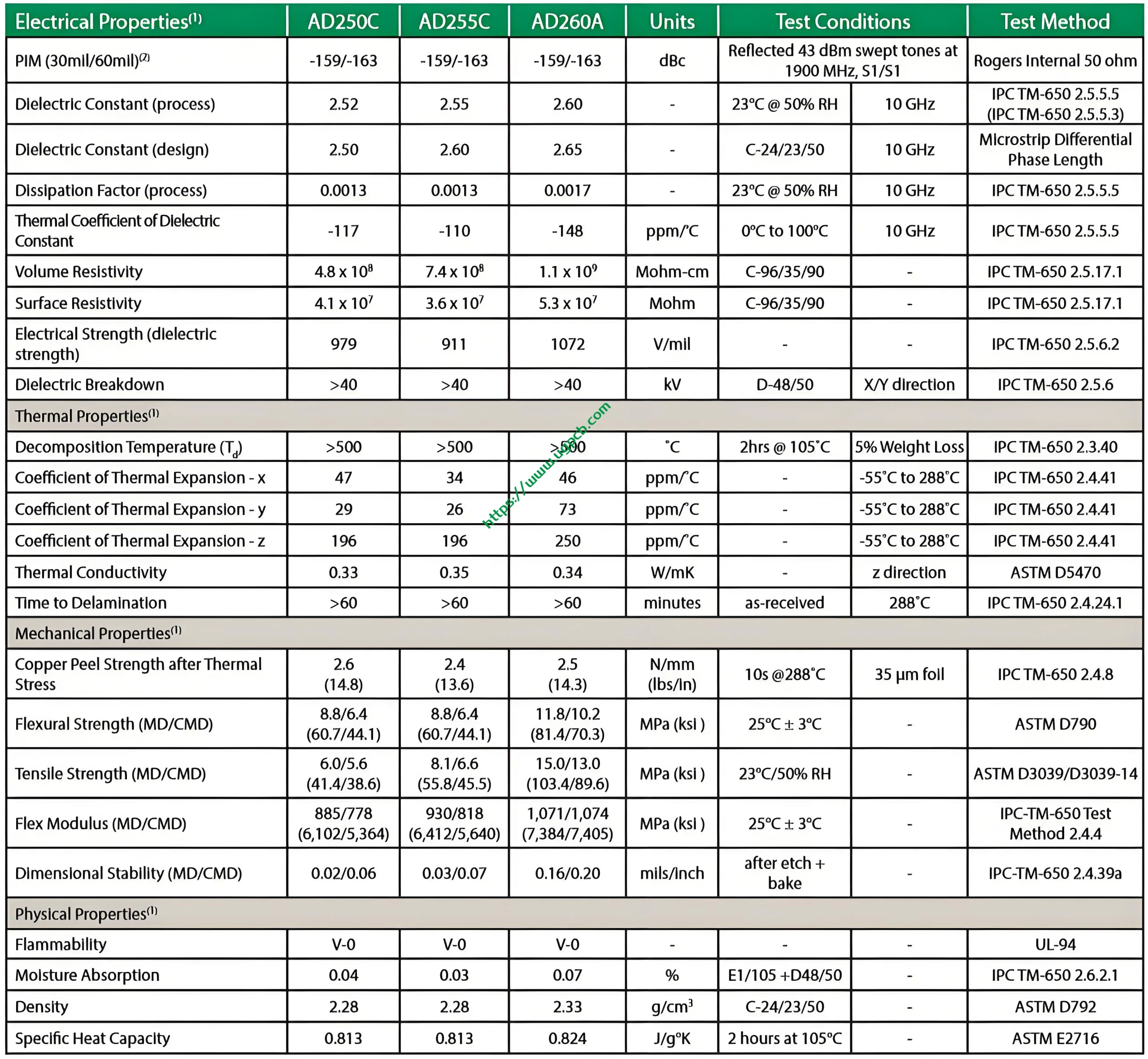

These advanced materials integrate the excellent thermal properties of fluoropolymer resin systems with carefully selected ceramic materials and glass fiber reinforcements. The result is a series of laminates characterized by low loss (DF = 0.0014 at 10GHz), minimal thermal expansion, and reduced passive intermodulation (PIM). Notably, the AD250C variant also marks a significant improvement over previous generations in terms of cost efficiency.

Stability and Reliability Across Frequencies and Temperatures

The stability of PTFE combined with low-loss characteristics across a broad frequency and temperature range makes Rogers (Арлон) AD250C, AD255C, and AD260A ideal for various microwave and RF applications. The inclusion of differential dispersion ceramics enhances thermal stability, offering lower coefficients of thermal expansion (КТР) and higher phase stability at elevated temperatures.

Compatibility and Reliability Enhancements

Роджерс (Арлон) AD250C, AD255C, and AD260A microwave high-frequency PCB materials are fully compatible with standard PTFE printed circuit board substrate processes. Their low z-axis thermal expansion significantly improves the reliability of plated through-hole (ПТХ) connections compared to typical PTFE base materials. Кроме того, low X-Y expansion enhances the reliability of BGA solder joints.

Material Composition and Advantages

The unique composition of Rogers (Арлон) AD250C, AD255C, and AD260A includes fluoropolymer resin, specific ceramic fillers, and glass fiber support materials. This combination yields dielectric laminates with low loss, robust mechanical toughness, stable dielectric constants, and low passive intermodulation (PIM).

Detailed Product Features

- Strictly Controlled Dielectric Constant: ad250C ± 0.04, ad255C ± 0.04, ad260A ± 0.04

- Low Loss Tangent: 0.0014 at 10GHz

- Enhanced Thermal Conductivity: Superior to traditional PTFE/glass fiber

- Stable Dielectric Constant: Maintainable across a wide range of frequencies and temperatures

- High Peel Strength Copper Foils: Available in both reverse processing and im series configurations

Key Advantages

- Consistent Antenna Performance: Ensures reliable operation.

- Low Insertion Loss & High Antenna Efficiency: Maximizes signal strength and efficiency.

- Increased Power Capacity: Supports higher power applications.

- Stable Frequency Band Performance: Unaffected by weather conditions.

- Ultra-Low PIM Values: As low as -165 dBc, ensuring minimal signal interference.

Typical Applications

- Base Station and Distributed Antenna Feed Networks: Ensures efficient signal distribution.

- Commercial Antennas: Versatile for various commercial uses.

- Digital Audio Broadcasting (DAB): Clear and reliable audio transmission.

- Patch Antennas (GNSS, GPS, SDAR): Precision positioning and navigation.

By integrating these advanced materials into your designs, you can achieve superior performance and reliability for high-frequency applications.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ