Introduction to Rogers TMM Series PCB Materials

Rogers TMM Series PCB materials, включающий такие варианты, как TMM3, ТММ4, ТММ6, ТММ10, ТММ10i, и ТММ13i, представляют собой сложную смесь композитных материалов, объединяющую керамику, углеводороды, and thermosetting polymers. This unique composition grants these materials exceptional properties for high-frequency microwave applications.

Unmatched Performance Characteristics

Electrical Stability and Consistency

The TMM series boasts a low dielectric constant thermal change rate, ensuring minimal signal distortion over temperature variations. Its thermal expansion coefficient aligns seamlessly with copper foil, promoting consistent electrical performance and mitigating issues related to thermal mismatch. These attributes make TMM materials highly suitable for demanding stripline and microstrip circuit designs where reliability is paramount.

Processing Advantages Over Alumina Substrates

Unlike traditional alumina filler substrates, TMM materials offer significant manufacturing benefits. They facilitate larger copper cladding options and are compatible with standard PCB fabrication processes, enhancing production efficiency without necessitating specialized equipment or techniques.

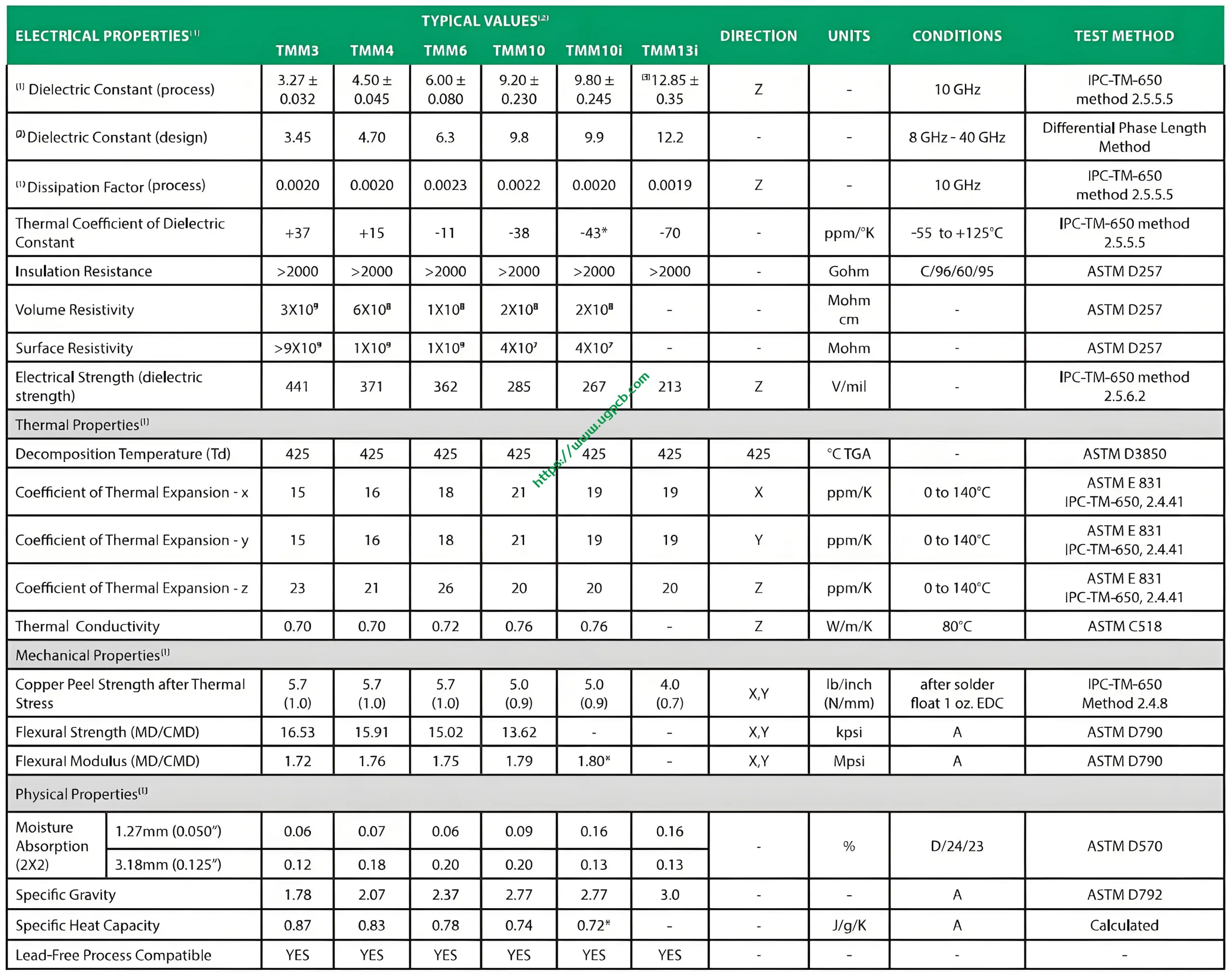

Customizable Dielectric Constants and Thickness Options

TMM materials provide a broad range of dielectric constants (3 к 13) and thicknesses (0.015 к 0.500 дюймы), all while maintaining stringent tolerance levels of ±0.0015 inches. This flexibility empowers designers to tailor their PCB stack-ups precisely to meet specific application requirements.

Key Advantages of TMM Microwave PCB Materials

- Versatile Permittivity Range: Catering to diverse design needs with adjustable dielectric constants.

- Superior Mechanical Strength: Resistant to creep flow and cold flow, ensuring structural integrity under varying conditions.

- Stable Dielectric Properties: Minimal dielectric constant fluctuation with temperature changes, crucial for high-precision applications.

- Thermal Compatibility: Matches copper foil’s thermal expansion, safeguarding plated through-hole reliability.

- Chemical Resistance: Unaffected by common chemicals, preserving integrity during production and assembly.

- Reliable Wire Bonding: Thermosetting resin composition supports dependable wire bonding processes.

- Processing Simplicity: Standard PCB manufacturing techniques apply, eliminating the need for complex or proprietary methods.

- Eco-Friendly and Compliant: TMM10 and TMM10i variants are RoHS certified, underscoring commitment to environmental sustainability.

Заключение

In summary, Rogers TMM Series PCB materials stand out in the realm of high-frequency microwave circuit boards due to their comprehensive advantages. From unparalleled electrical stability and mechanical robustness to ease of processing and environmental compliance, they present an ideal solution for advanced electronic applications requiring utmost reliability and performance consistency.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ