Understanding Rogers PCB Materials: A Comparison of RO4835 and RO4350

The dielectric constant and loss factor of Rogers RO4835 and Rogers RO4350 are essentially the same. However, the key difference lies in the composition of the plates. Rogers RO4835 incorporates an antioxidant filler on top of the base material found in Rogers RO4350. This enhancement has enabled Rogers RO4835 to pass automotive safety regulations, making it particularly suitable for designing automotive anti-collision radar antennas.

Rogers PCB RO4835 Material Overview

Rogers RO4835 PCB material is renowned for its high stability at elevated temperatures and significant resistance to oxidation. These properties make it a preferred choice for various demanding applications.

Key Features of RO4835 Laminates

- Low Loss and Cost-Effective: RO4835 laminates are designed to be low-loss materials, providing cost-effective circuit fabrication that is compatible with standard epoxy/glass (FR-4) processes.

- Proprietary Copper Foil: These laminates are available with Rogers’ proprietary LoPro Reverse treated copper foil, which is ideal for applications requiring low insertion loss.

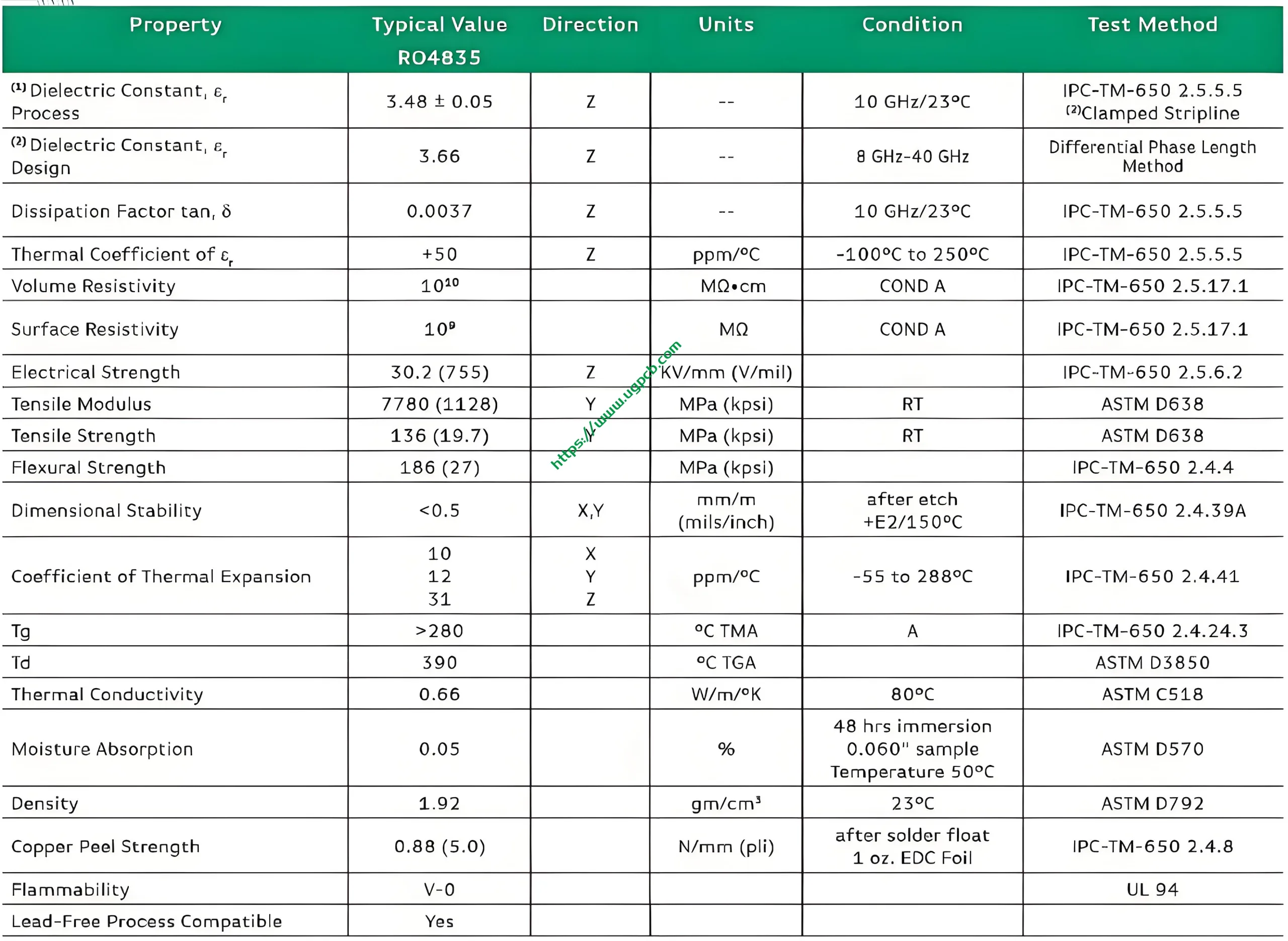

Detailed Specifications of Rogers RO4835

Compliance and Electrical Properties

- RoHS Compliant: Suitable for applications requiring UL 94 V-0 compliance.

- IPC-4103 Compliant: Ensures adherence to industry standards.

- Dielectric Constant (Dk): 3.48 +/- .05

- Dissipation Factor at 10 GHz: 0.0037

Benefits of Using Rogers RO4835

- Enhanced Oxidation Resistance: Offers ten times improved oxidation resistance compared to traditional thermoset laminates.

- Superior High-Frequency Compatibility: Due to excellent electrical performance, it is highly suitable for high-frequency applications.

- Reliable Construction: Ensures no blistering or delamination, maintaining the integrity of Plated through Hole (PTH) construction.

By understanding these features and benefits, users can make more informed decisions when selecting the appropriate Rogers PCB material for their specific needs.

UGPCB LOGO

UGPCB LOGO