Standardizing Rogers RT/duroid 5880 PTFE Glass Fiber Sheet Processing and Applications

To process RT/duroid 5880 PTFE glass fiber sheet, the following requirements should be paid attention to in order to ensure the dimensional stability.

Enhancing Bonding Force of the Inner Medium Surface

In order to increase the bonding force of the inner medium surface, it is necessary to protect the roughness of the medium surface after etching. This ensures a better adhesion between layers.

Treatment for Pure PTFE Material Surface

For the surface of the medium that is pure PTFE material, it is recommended to do sodium naphthalene or plasma treatment. These methods improve the surface’s receptivity to subsequent processing steps.

Pre-Pressing Board Surface Preparation

Before pressing, make sure that the surface of the board is clean and dry. It cannot be brushed mechanically as this could damage the delicate surface. Proper cleaning ensures optimal adhesion and performance.

Choosing the Right Copper Surface Treatment

According to the type of bonding sheet, choose the appropriate inner copper surface treatment, whether oxidation or oxidation substitution method. It is recommended that the PCB processing factory strictly follows the Teflon PCB, PTFE multilayer board processing guide to set the process flow.

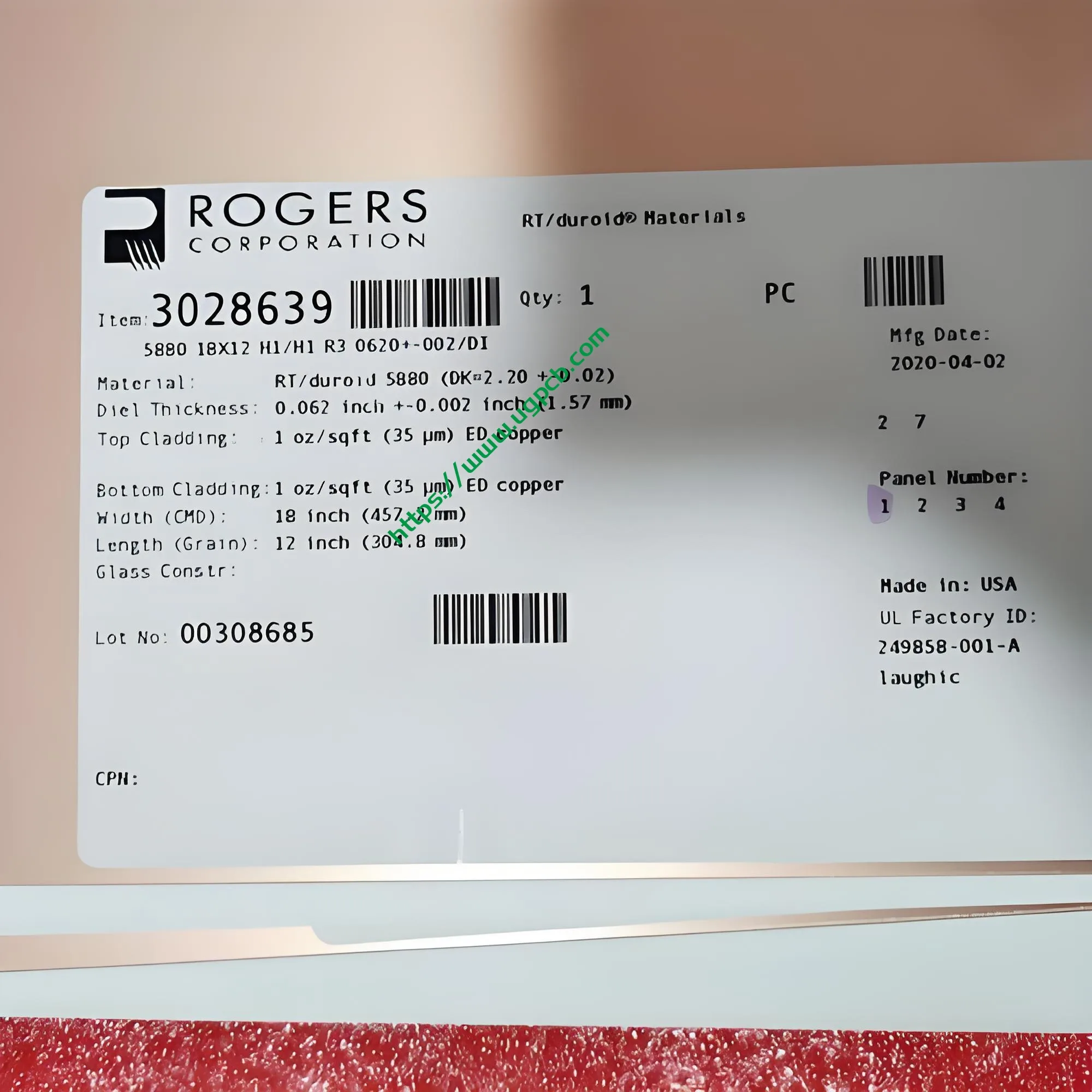

Rogers RT/Duroid 5880 High Frequency PCB Overview

Rogers RT/Duroid 5880 high frequency PCB is made of PTFE glass fiber reinforced material. High frequency circuit design always has strict requirements for the dielectric constant of printed circuit boards. The dielectric constant of RT5880 measured at 10 GHz working frequency is only 2.2, which is obviously lower than that of similar materials on the market at present. Therefore, from the perspective of performance parameters and production cost, the board is more suitable for high-frequency design and application than similar products. At the same time, the dielectric loss of the plate measured under the same standard is only 0.0009. The extremely low dielectric loss makes it very suitable for high frequency and wide band design applications requiring minimum dispersion and loss. It is mainly used in high-frequency circuit board point-to-point digital radio antenna, microstrip and stripline circuit, millimeter wave application, missile guidance system, military radar system, and commercial aviation telephone.

Characteristics of Rogers 5880 PCB

The characteristics of Rogers 5880 PCB are as follows:

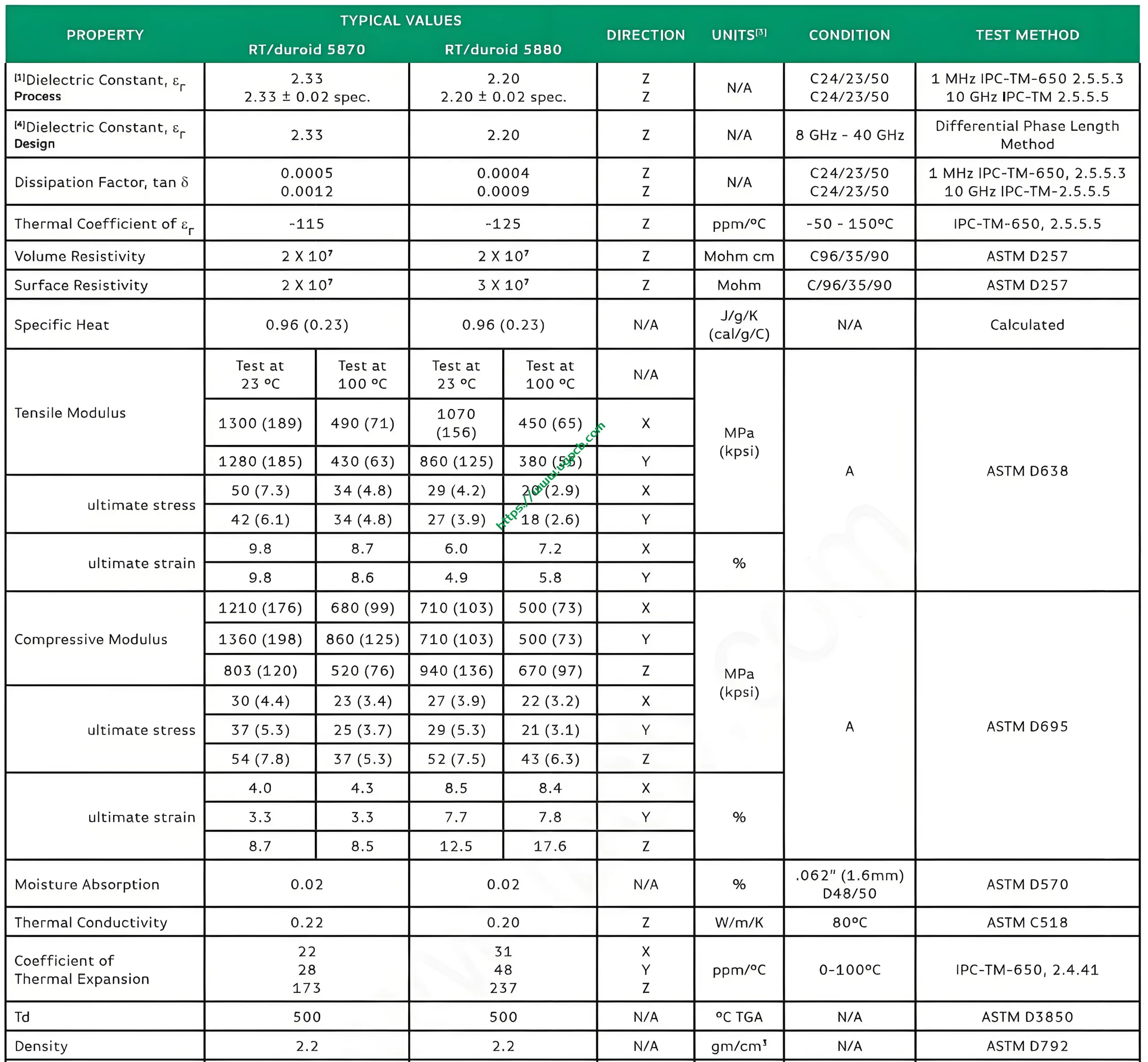

Very Low Dielectric Constant

Measured at 10 GHz, the dielectric constant is 2.20 ± 0.02.

Very Low Dielectric Loss

Measured at 10 GHz, the dielectric loss factor is 0.0009.

Rogers 5880 PCB Material Composition

Rogers RT/duroid 5880 (Rogers 5880) material consists of PTFE composites reinforced with glass microfibers. The RT/duroid 5880 laminates have a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Benefits of Rogers RT/Duroid 5880

The benefits of Rogers RT/Duroid 5880 include:

Uniform Electrical Properties over Wide Frequency Range

The material maintains uniform electrical properties across a wide frequency range, ensuring consistent performance.

Ease of Cutting and Machining

It is easily cut, shared, and machined to shape, facilitating manufacturing processes.

Resistance to Solvents and Reagents

Resistant to solvents and reagents used in etching or plating edges and holes, enhancing durability.

Ideal for High Moisture Environments

Well-suited for applications in high moisture environments due to its stable properties.

Well-Established Material

As a well-established material, it offers reliability and predictability in performance.

Lowest Electrical Loss for Reinforced PTFE Material

It provides the lowest electrical loss among reinforced PTFE materials, optimizing signal integrity.

UGPCB LOGO

UGPCB LOGO