Introduction

In modern electronics manufacturing, เทคโนโลยี Mount Surface (SMT) has become the core process for PCB assembly. อย่างไรก็ตาม, as component sizes continue to shrink and soldering processes become more complex, the reliability of solder joint strength has become increasingly critical. Solder joint strength not only directly impacts the mechanical performance of products but also determines their long-term reliability in harsh environments. This article explores the specifications and evaluation criteria for pull and shear testing of SMT component solder joint strength through detailed experimental data and professional analysis, providing scientific insights and practical guidance for the industry.

Experimental Methods and Design

Experimental Design

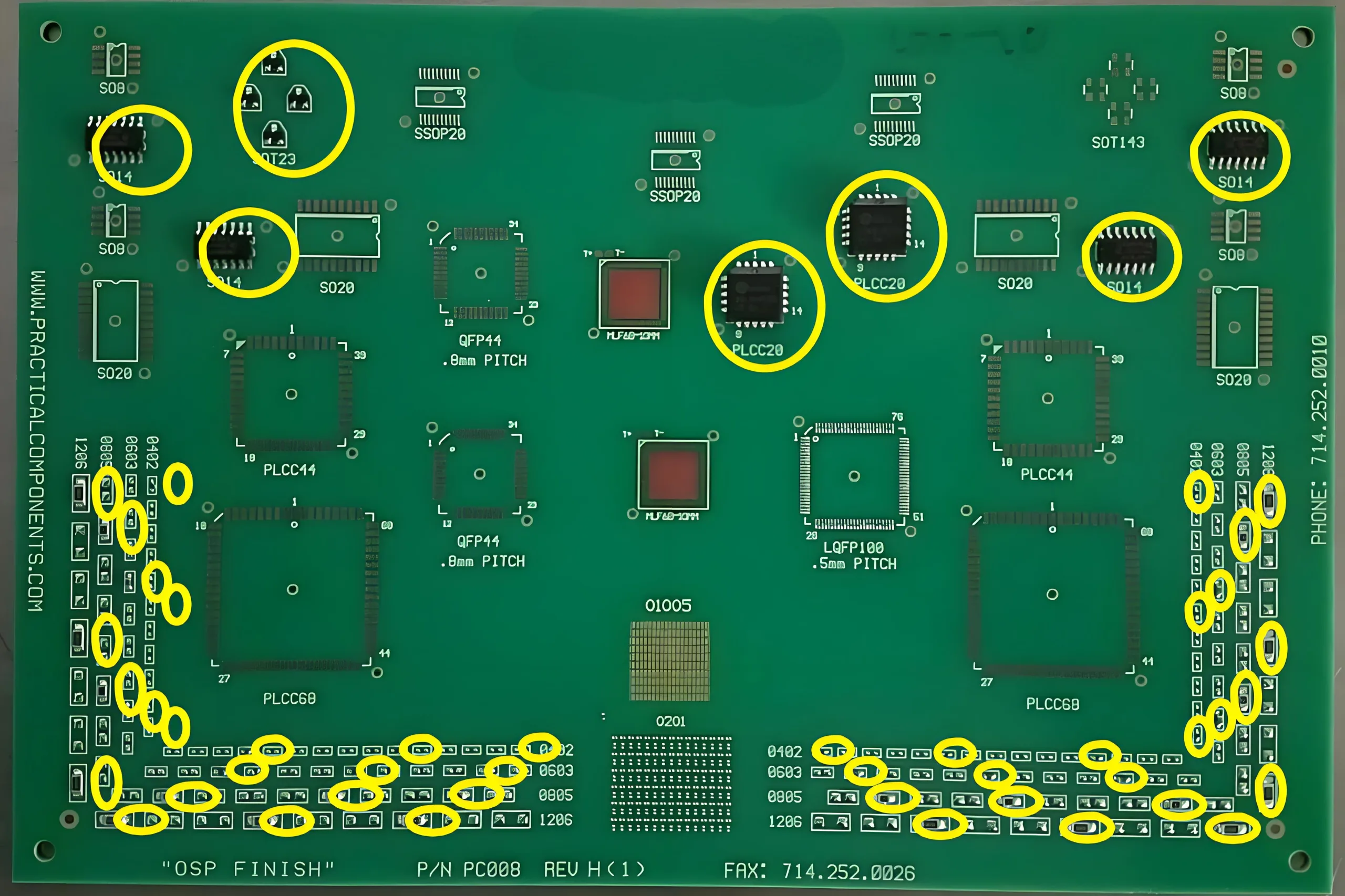

The experiment selected a variety of common SMT components, including passive components such as 0402, 0603, 0805, และ 1206, as well as leaded components like SOT23, SO14, and PLCC20. By adjusting solder paste volume, stencil thickness, and printing parameters, different soldering conditions were simulated to evaluate the factors affecting solder joint strength.

Solder Paste Volume and Stencil Design

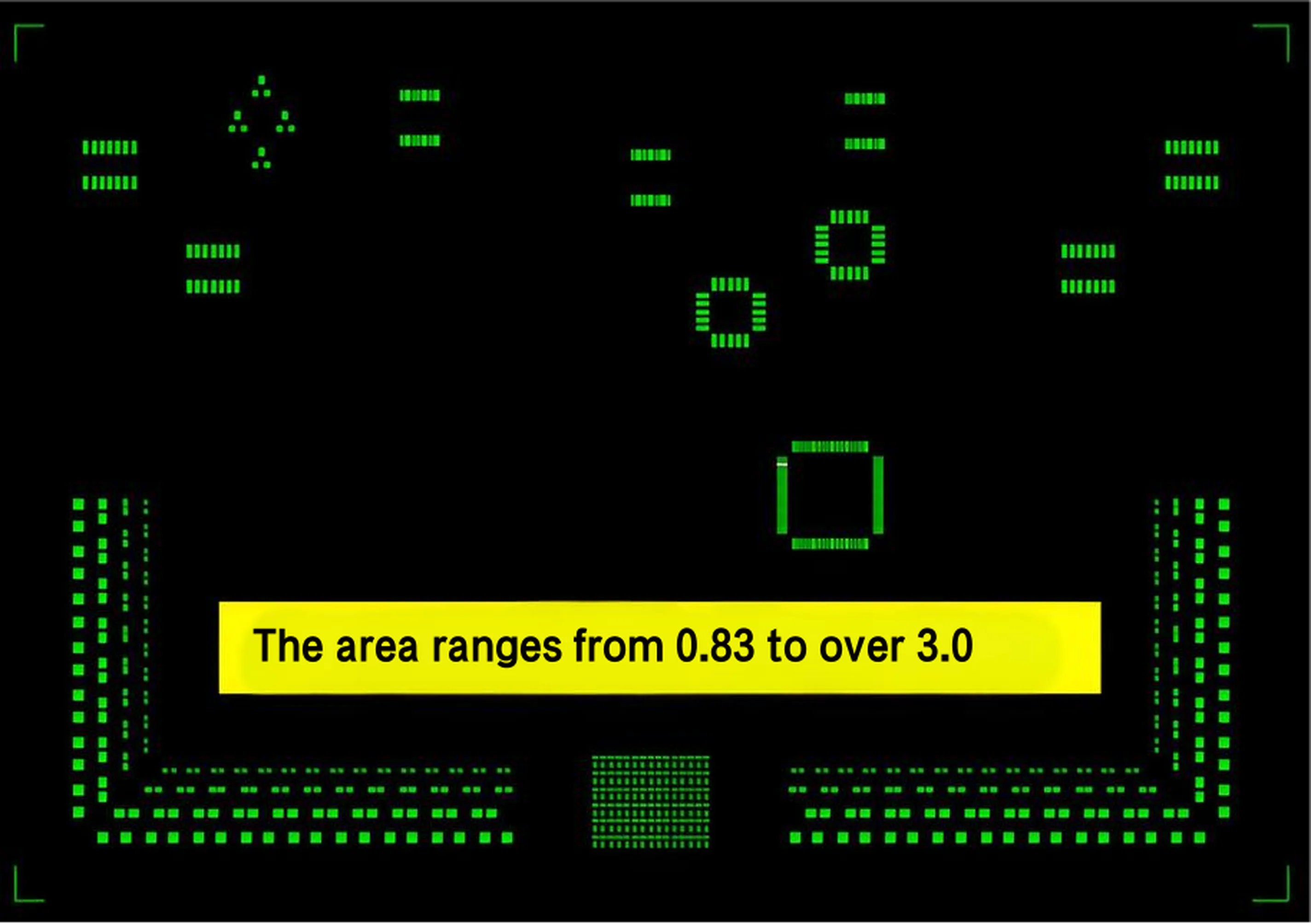

Solder paste volume is one of the key factors influencing solder joint strength. The experiment designed a gradient of solder paste volumes ranging from 25% ถึง 125%, combined with different stencil thicknesses (51µm to 102µm), to study the relationship between solder paste transfer efficiency and solder joint strength. Experimental data showed that reducing solder paste volume significantly decreases solder joint strength, especially for passive components, where a 50% solder paste volume approaches the lower acceptable limit.

Formula: Solder Paste Transfer Efficiency = (Actual Solder Paste Volume / Stencil Aperture Volume) × 100%

ตัวอย่างเช่น, the transfer efficiency for a 0402 component at 25% solder paste volume was 31%, while at 125%, it reached 138%. This data provides critical insights for optimizing solder paste printing processes.

Printing Parameters and Reflow Profile

Parameters such as printing speed, squeegee pressure, and separation speed significantly affect the uniformity and transfer efficiency of solder paste. The experiment employed a printing speed of 30 mm/sec, a squeegee pressure of 5.0 kg, and a 10-zone reflow oven to ensure process control. Key parameters of the reflow profile included:

- Soak Time (150-200องศาเซลเซียส): 70-75 ไม่กี่วินาที

- Time Above Liquidus (>221องศาเซลเซียส): 63-70 ไม่กี่วินาที

- Peak Temperature: 243-249องศาเซลเซียส

These parameters ensured proper solder joint formation while avoiding defects caused by overheating.

Results and Discussion

Solder Joint Strength Testing

Pull and shear tests were conducted to evaluate the solder joint strength of different components. ตัวอย่างเช่น:

- 0402 ส่วนประกอบ: The required shear force standard was ≥0.65Kgf. Experimental data showed a shear force of 0.68Kgf at 50% ปริมาณการวางประสาน, close to the acceptable threshold.

- 1206 ส่วนประกอบ: The required shear force standard was ≥3.00Kgf. Experimental data showed a shear force of 3.15Kgf at 100% ปริมาณการวางประสาน, demonstrating good performance.

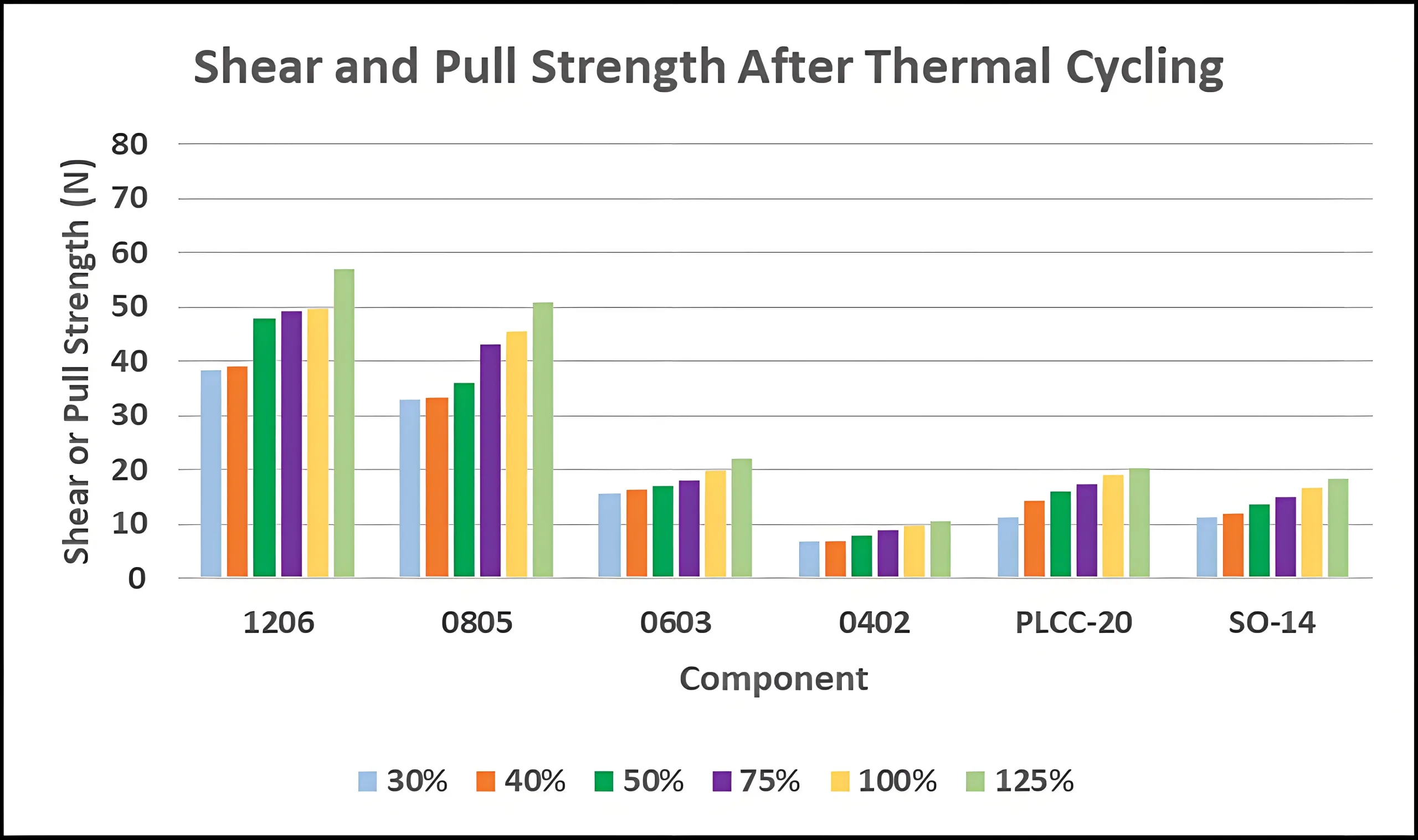

Impact of Thermal Cycling on Solder Joint Strength

The experiment also simulated thermal cycling conditions (-40°C to 125°C, 1000 cycles) to study the long-term reliability of solder joint strength. Results indicated that thermal cycling significantly reduces solder joint strength, particularly under low solder paste volume conditions. ตัวอย่างเช่น, the shear force for a 0402 component at 25% solder paste volume decreased from 0.68Kgf to 0.55Kgf after thermal cycling, falling below the acceptable standard.

Analysis of Solder Joint Defects

Based on IPC-A-610 and J-STD-001 มาตรฐาน, the experiment conducted a detailed analysis of solder joint defects. Results showed that insufficient solder paste volume (e.g., 25%) led to an increase in defects such as solder balls and skew off pad. ตัวอย่างเช่น, the defect rate for solder balls in 0402 components was 17% ที่ 25% solder paste volume but decreased to 3% ที่ 125%.

Conclusions and Recommendations

Optimization of Solder Paste Volume

The experiment demonstrated that solder paste volume significantly impacts solder joint strength. It is recommended that in actual production:

- For passive components, solder paste volume should be maintained above 50% to ensure solder joint strength.

- For leaded components (e.g., PLCC20 and SO14), solder paste volume can be reduced to 40%, but further research is needed for components like SOT23.

Standardization of Process Parameters

Standardizing printing parameters and reflow profiles is crucial for ensuring solder joint strength. Our UGPCB assembly factory customizes detailed process parameter specifications based on equipment and component types, followed by validation and adjustments.

Enhancing Long-Term Reliability

Thermal cycling experiments revealed that solder joint strength gradually declines over time. For applications requiring high reliability, it is recommended to use higher solder paste volumes and optimized PCBA soldering processes to enhance long-term reliability.

บทสรุป

Pull and shear testing of SMT solder joint strength is not only a critical quality control measure but also a key factor in improving the reliability of PCBA products. ในอนาคต, as component sizes continue to shrink, UGPCB will innovate and research new processes and methods. While serving our customers, we aim to collaborate with industry peers to drive advancements in electronics manufacturing and propel the progress of the PCBA assembly industry.

โลโก้ UGPCB

โลโก้ UGPCB