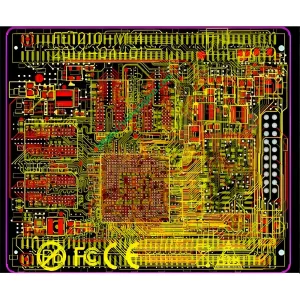

การออกแบบ PCB ความเร็วสูง

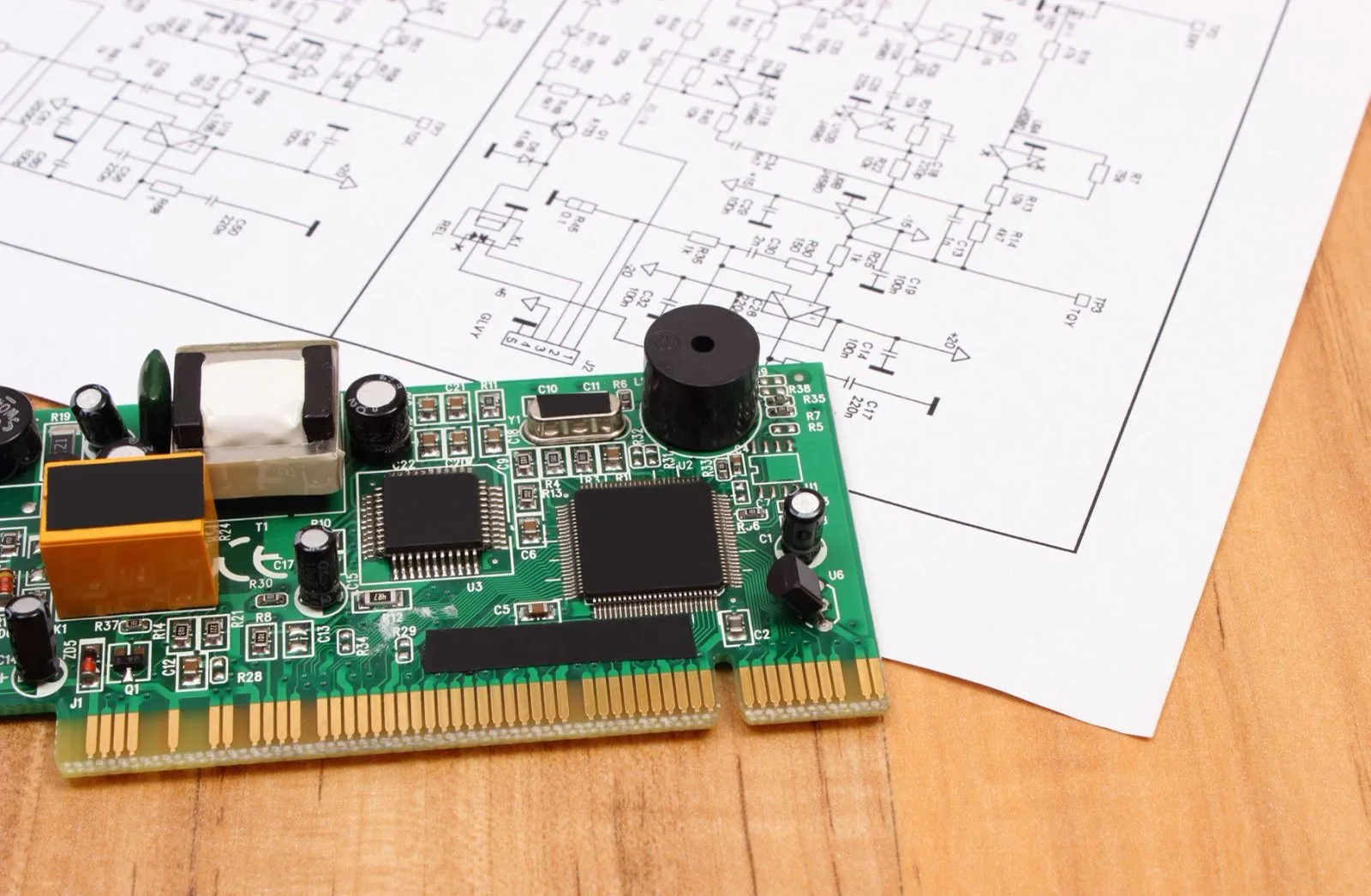

Core Challenges and Technical Value of High-Speed PCB Design

In fields such as 5G communications, AI servers, high-speed computing, and autonomous driving, high-speed PCB design is the core technology ensuring signal integrity (SI), ความสมบูรณ์ของพลังงาน (PI), และความเข้ากันได้ของแม่เหล็กไฟฟ้า (EMC). The key technical challenges include:

- Ultra-High-Speed Signal Loss: Skin effect, dielectric loss, and impedance discontinuity at rates above 28 Gbps.

- Timing Synchronization: Length matching tolerance for multi-channel differential signals ≤5 mil (0.127 มม).

- Power Noise Suppression: Power ripple ≤30 mV under full load conditions (@100 MHz).

- 3D Electromagnetic Interference: Crosstalk suppression >40 dB at GHz frequencies.

UGPCB leverages full-link co-design and multi-physics simulations to help clients achieve critical metrics such as 56 Gbps PAM4 signal loss ≤3 dB/inch, eye diagram margin ≥20%, and power-ground plane impedance <1 mΩ, providing uncompromising physical layer support for high-speed systems.

Professional Capability Matrix: Full-Stack Technology from Theory to Production

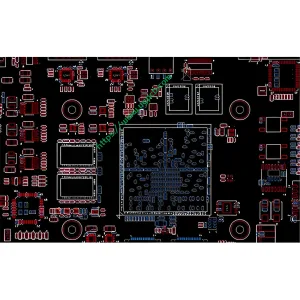

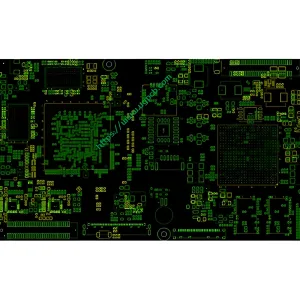

1. High-Frequency Material Selection and Stackup Architecture

- Dielectric Material Library: Includes Megtron6, Tachyon100G, and Isola FR408HR, with Dk values of 2.8–3.8 and Df ≤0.002 (@10 GHz).

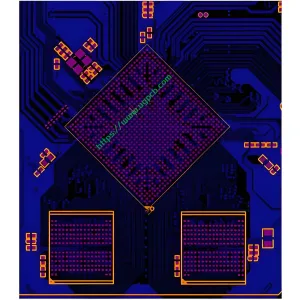

- Hybrid Stackup Design: Supports 20+ layer back-drill structures with stub length control <8 MIL.

- Copper Foil Optimization: Combines HVLP (ultra-low profile copper) with surface treatment for roughness Ra <0.3 μm.

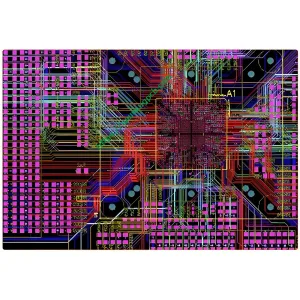

2. Precision Impedance Control and Routing Strategies

- Multi-Mode Impedance Design: Single-ended 50 Ω, differential 100 Ω, and coplanar waveguide 75 Ω with ±5% tolerance.

- Topology Optimization: Cadence Sigrity-based auto-routing for Fly-by/Daisy Chain topology switching.

- Via Optimization: Dynamic anti-pad sizing compensation ensures via impedance fluctuation ≤3%.

3. Signal Integrity Enhancement

- Pre-Emphasis and Equalization: Pre-simulates CTLE/DFE parameters to compensate for channel loss.

- Power Integrity Solutions: MLCC + decoupling capacitor matrix design with target impedance (Ztarget) <0.1 Ω (@100 MHz–5 GHz).

- 3D Shielding Architecture: Ground via arrays with localized shielding for isolation >60 dB @28 GHz.

4. Advanced Manufacturing Process Assurance

- Laser Direct Imaging (LDI): Line width tolerance ±8%, minimum line width/spacing 40 μm.

- Pulse Plating Via Fill: Via thickness uniformity >95%, void rate <5%.

- Plasma Cleaning: High-frequency hole wall roughness Ra <1 μm, ensuring 56 Gbps signal transmission.

Full-Process Technical Support System

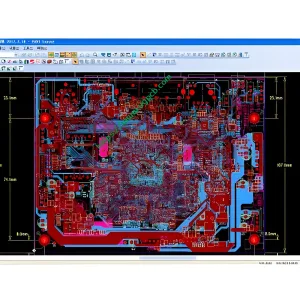

PCB Design Verification Phase

- Multi-Physics Co-Simulation: ANSYS HFSS + SIwave + Q3D with accuracy error <3%.

- Thermal-Mechanical Coupling Analysis: Flotherm® validates heatsink layout and PCB warpage (<0.1%).

- Time Domain Reflectometry (TDR): Impedance continuity testing with ±1 Ω resolution.

PCB Manufacturing Process Control

- Back-Drilling Depth Control: Mechanical + laser drilling with stub accuracy ±2 mil.

- Layer Alignment System: X-ray alignment accuracy ±15 μm, ensuring >98% yield for 24+ layer HDI boards.

- Aoi + ICT Inspection: Open/short defect detection rate >99.99%.

Testing and Certification

- 56 Gbps BER Testing: BERTScope bit error rate <1E-12.

- EMI Pre-Compliance Testing: 10m chamber radiation testing (30 MHz–40 GHz).

- Industry Standard Certifications: IPC-6012 Class 3, ISO-26262 (ASIL-D) automotive certification.

Typical Application Scenarios

- AI Servers: NVSwitch interconnect boards supporting 72-channel 112 Gbps PAM4 signaling.

- 5G Base Stations: Millimeter-wave AAU mainboards operating at 24.25–52.6 GHz.

- Autonomous Driving Domain Controllers: 16-layer automotive PCBs compliant with AEC-Q200 Grade 2.

- High-Speed Optical Modules: 800G OSFP PCBs integrating TIA/Driver bare-die packaging.

Service Models and Technical Support

- High-Speed Design Kit (HSDK): Standardized kits include stackup templates, design rules, and simulation models.

- 48-Hour Rapid Prototyping: 12-layer high-speed boards delivered within 72 ชั่วโมง, with flying probe test reports.

- Failure Analysis Services: TDR fault localization, cross-section analysis, and material thermal analysis (TGA/DSC).

- Certification Support: Full-process guidance for UL, CE, and FCC certifications.

From 56 Gbps to 224 Gbps

With over a decade of PCB design experience, 300+ successful high-speed PCB projects, UGPCB builds a comprehensive technical moat for your digital systems.

Contact our PCB design expert team now to obtain a customized Signal Integrity Design White Paper and free simulation consulting services!

อีเมล: sales@ugpcb.com

โลโก้ UGPCB

โลโก้ UGPCB

วีแชท

สแกนรหัส QR ด้วย WeChat