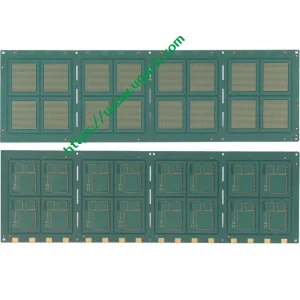

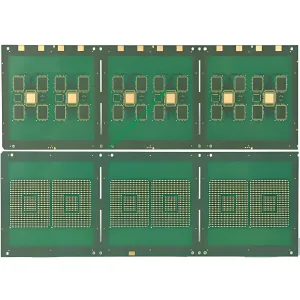

ATE Load board PCB Overview

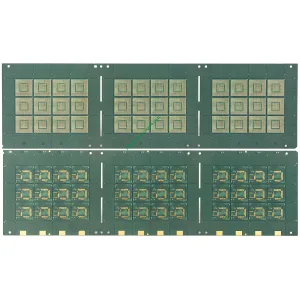

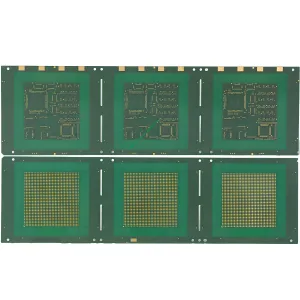

The ATE Load board PCB is a highly specialized printed circuit board designed for use in automated test equipment (ATE) systems. This advanced PCB supports the testing of electronic components and systems by simulating real-world loads. Below is a comprehensive introduction to the ATE Load board PCB, covering its general information, classification, materials, performance, structure, features, production process, and application scenarios.

การจำแนกประเภท

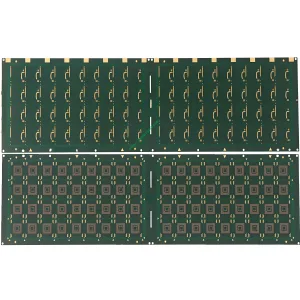

ATE Load board PCBs are classified based on their complexity, layer count, and specific application requirements. The model introduced here, ATE Load board PCB, is a 28-layer PCB, indicating its high complexity and capacity to handle intricate testing scenarios.

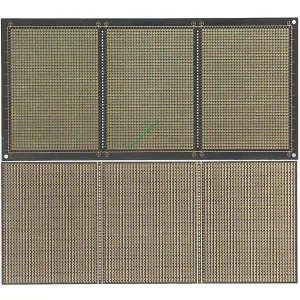

องค์ประกอบของวัสดุ

The ATE Load board PCB is constructed using TUC/TU872HF material, a high-performance substrate known for its excellent electrical and mechanical properties. This material ensures the PCB’s reliability and durability under demanding test conditions.

ลักษณะประสิทธิภาพ

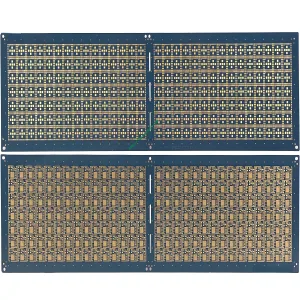

The ATE Load board PCB excels in several performance areas, including high current carrying capacity, low signal loss, and excellent thermal management. The use of 2OZ copper thickness for both inner and outer layers enhances its electrical conductivity and thermal dissipation capabilities. นอกจากนี้, the hard gold 3-15u surface finish provides superior corrosion resistance and solderability.

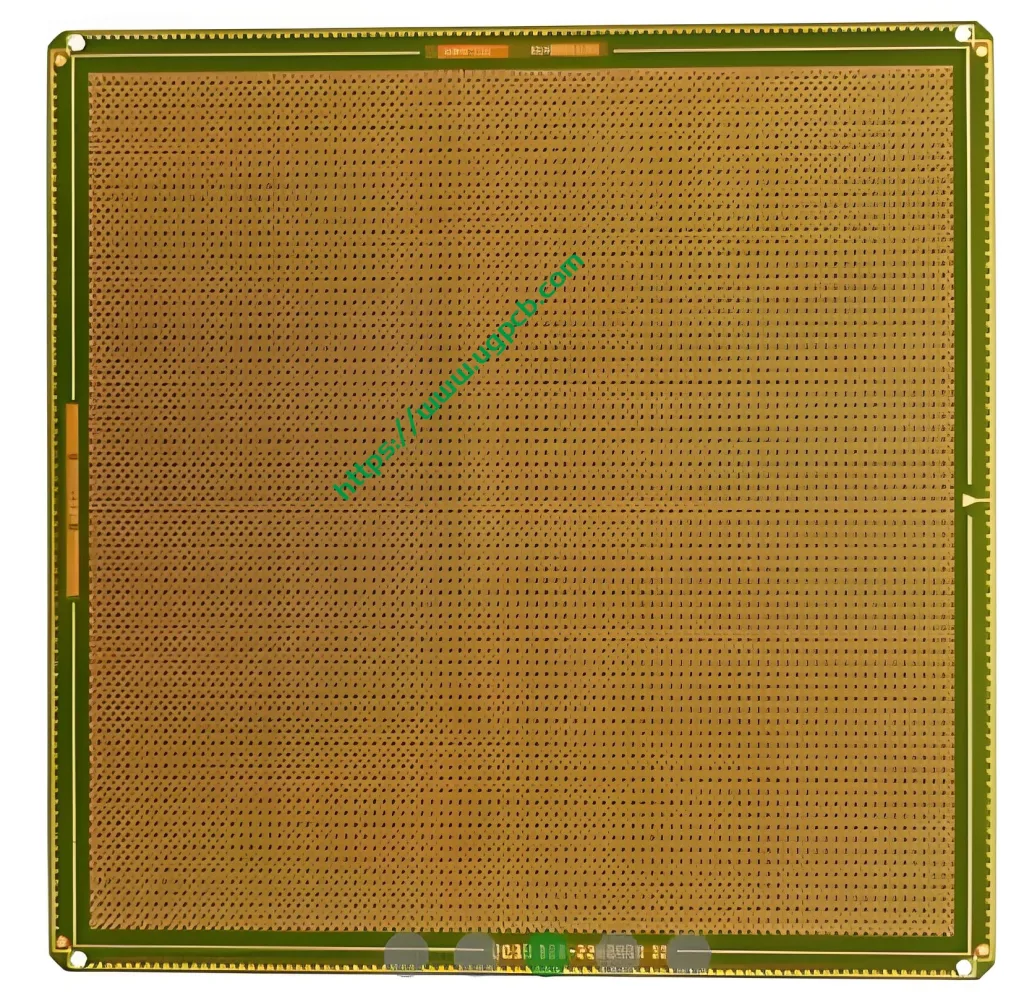

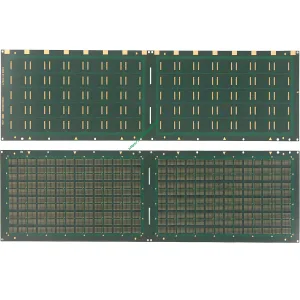

Structural Design

Structurally, the ATE Load board PCB features a board thickness of 5.0mm, providing a robust foundation for the complex circuitry and components. The yellow color not only adds a visual distinction but also aids in inspection and troubleshooting processes.

Distinctive Features

The ATE Load board PCB stands out with its unique features, including metal cladding for enhanced thermal conductivity and depth control drilling for precise component placement and interconnection. These features, combined with its high layer count and advanced materials, make it an ideal choice for ATE applications.

กระบวนการผลิต

The production of ATE Load board PCBs involves a series of sophisticated steps:

- การเตรียมวัสดุ: The TUC/TU872HF substrate is prepared and cut to the required dimensions.

- Copper Lamination: Copper foil is laminated to the substrate, with specific attention to the 2OZ thickness requirement.

- Circuit Patterning: The desired circuit patterns are etched onto the copper foil using precision etching techniques.

- Layer Stacking and Lamination: Multiple layers are stacked and laminated together, ensuring precise alignment and bonding.

- Drilling and Plating: Depth control drilling is performed to create holes for component mounting and interconnection. The holes are then plated to enhance conductivity.

- Metal Cladding: A metal layer is applied to the PCB surface to improve thermal conductivity and mechanical strength.

- Surface Finish Application: The hard gold 3-15u coating is applied to provide corrosion resistance and solderability.

- Final Inspection and Testing: The PCB undergoes rigorous inspection and testing to ensure compliance with specifications and performance requirements.

Application Scenarios

ATE Load board PCBs are primarily used in automated test equipment systems for the testing and validation of electronic components and systems. They are essential in the semiconductor industry, automotive industry, aerospace industry, and other sectors where high-reliability testing is crucial. By simulating real-world loads, ATE Load board PCBs enable engineers to verify the performance and reliability of electronic devices before they are deployed in actual applications.

โลโก้ UGPCB

โลโก้ UGPCB