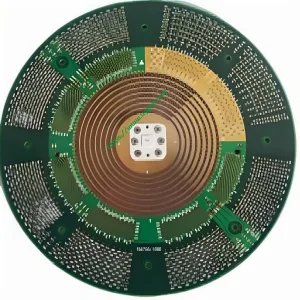

Copper-based LED car headlight PCB

LED car light double-sided copper substrate is a type of substrate used for manufacturing LED car lights, featuring double-sided copper foil layers that offer better thermal conductivity and electrical connectivity. The advantages of this substrate include:

Good thermal conductivity: The double-sided copper foil layers can effectively dissipate the heat generated by LED beads, reducing the temperature of the substrate and improving the reliability and lifespan of the LED beads.

Good electrical connectivity: The double-sided copper foil layers provide good electrical connectivity, making signal transmission between LED beads and circuit boards more stable and reliable.

Ease of manufacturing and processing: Double-sided copper substrates can be produced using traditional PCB manufacturing processes, facilitating automated production and processing to improve efficiency.

Good thermal stability: The double-sided copper substrate can work stably in high-temperature environments, suitable for the high temperatures found in car engine compartments.

Corrosion resistance and wear resistance: The double-sided copper substrate has corrosion resistance and wear resistance, capable of withstanding various corrosive and abrasive factors inside and outside the car, ensuring the stability and reliability of LED car lights.

The LED car light double-sided copper substrate has excellent thermal conductivity, การเชื่อมต่อไฟฟ้า, manufacturability, เสถียรภาพทางความร้อน, ความต้านทานการกัดกร่อน, and wear resistance, making it suitable for manufacturing high-performance, highly reliable LED car lights.

In addition to the LED car light double-sided copper substrate, there are other types of car light substrates, รวมทั้ง:

Copper-based LED car headlight PCB

Aluminum substrate: An aluminum substrate is a type of car light substrate made from aluminum, offering high thermal conductivity, ต้นทุนต่ำ, และความสะดวกในการประมวลผล, widely used in car headlights, fog lights, and other areas.

Ceramic substrate: A ceramic substrate is a type of car light substrate made from ceramic, featuring high thermal conductivity, high insulation, and high heat resistance, suitable for manufacturing high-temperature, high-reliability car lights.

Glass substrate: A glass substrate is a type of car light substrate made from glass, known for its high transparency, ความต้านทานอุณหภูมิสูง, and corrosion resistance, suitable for manufacturing high-brightness, high-color-temperature LED car lights.

PI substrate: A PI substrate is a type of car light substrate made from polyimide, offering high heat resistance, high insulation, and chemical resistance, suitable for manufacturing high-temperature, high-pressure, high-frequency automotive electronic components.

LED car light double-sided copper substrates and other types of car light substrates are widely used in the automotive lighting field, including but not limited to:

LED car headlights.

Headlights: LED headlights feature high brightness, low energy consumption, and long lifespan, enhancing vehicle driving safety and comfort.

Tail lights: LED tail lights have high brightness, low energy consumption, and high-temperature resistance, improving vehicle driving safety and reliability.

Fog lights: LED fog lights have high penetration, low energy consumption, and high-temperature resistance, enhancing vehicle driving safety and comfort in rainy and foggy weather.

Daytime running lights: LED daytime running lights have high brightness, low energy consumption, and long lifespan, enhancing vehicle driving safety and visibility.

Brake lights: LED brake lights have high brightness, low energy consumption, and high-temperature resistance, alerting following vehicles during braking, enhancing vehicle driving safety and comfort.

LED car light double-sided copper substrates and other types of car light substrates are important components in the automotive lighting field, improving vehicle driving safety and comfort, and promoting the development of the automotive industry.

โลโก้ UGPCB

โลโก้ UGPCB