Power Supply Flow and Filter Capacitor

After the power supply comes in, it goes to the filter capacitor first. After it comes out of the filter capacitor, it is sent to the back equipment. Because the wiring on the PCB board is not an ideal wire, there is resistance and distributed inductance. If the power is taken from the front of the filter capacitor, the ripple will be relatively large, and the filtering effect will be poor.

Line Layout Considerations

The line should be paid attention to: if it is possible to make a wide line, it must not be thin, there must be no sharp chamfering, and no right angle should be used for turning. The ground wire should be as wide as possible. It is better to use a large area of copper coating. This docking point problem has been greatly improved.

Capacitors for Filtering and Decoupling

Capacitors are set for switching devices (gate circuits) or other components that need filtering / decoupling. These capacitors should be arranged as close as possible to these components. If they are too far away, they will not work. When laying PCB (power board), the following safety regulations should be considered:

Safety Distances Before Fuse

The minimum safety distance between the two wires before the fuse and that between the two wires and the enclosure or internal grounding of the AC power supply line shall not be less than 6 มม, and the minimum safety distance between the two wires and the enclosure or internal grounding shall not be less than 8 มม.

Wiring Requirements After Fuse

The minimum creepage distance between zero and live wires shall not be less than 3mm.

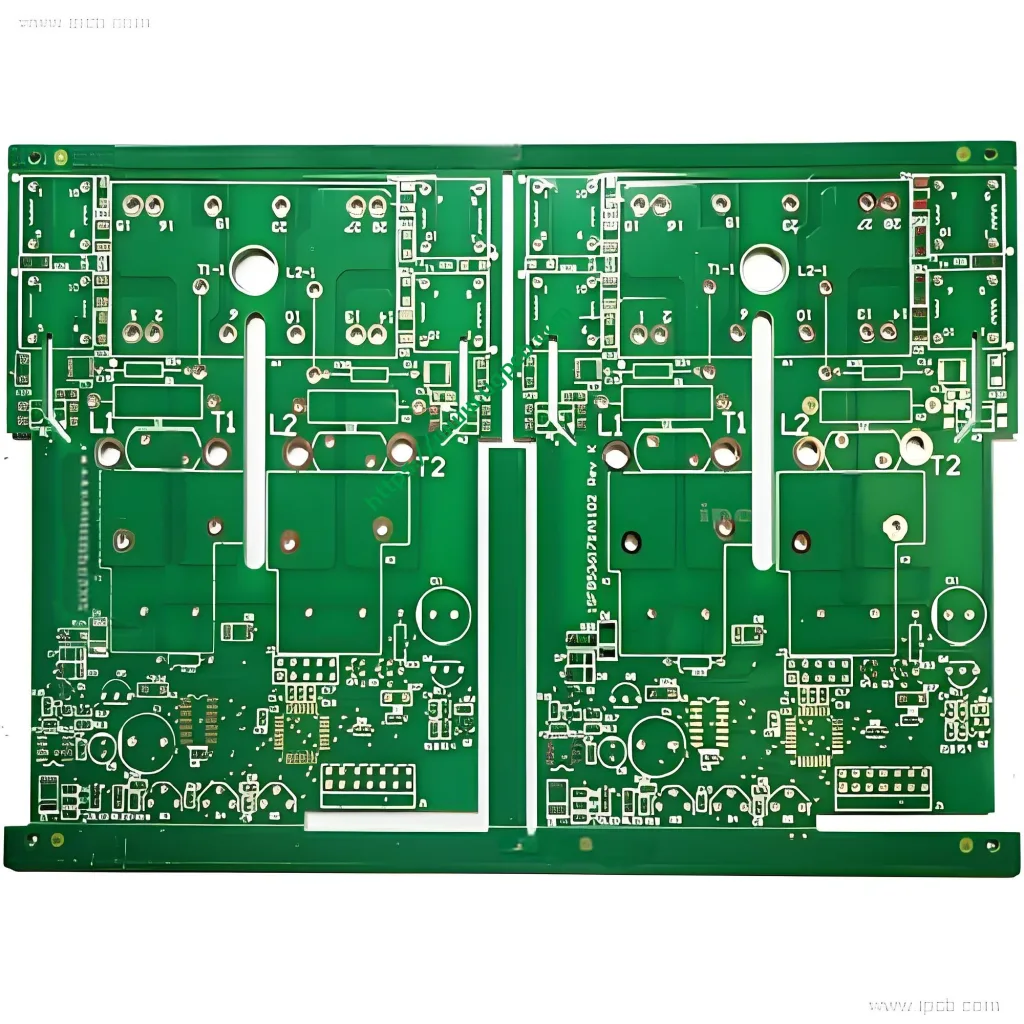

Creepage Distance Between High and Low Voltage Areas

The minimum creepage distance between high voltage area and low voltage area is not less than 8mm. If it is less than or equal to 8mm, a 2 mm safety slot must be opened.

Silk Screen Printing for High-Voltage Area

The high-voltage area shall be provided with silk screen printing of high-voltage warning signs, i.e. triangle symbols including exclamation marks; the high-voltage area shall be framed with silk screen printing, and the frame bar silk screen printing shall not be less than 3mm.

Safe Distance for High Voltage Rectifier Filter

The minimum safe distance between positive and negative of high voltage rectifier filter is not less than 2mm. The design and development process is briefly described as follows:

Schematic Diagram

Make the schematic diagram according to the design.

Network Table

After the schematic diagram is compiled, the corresponding network table can be generated.

Keep Out Layer

Keep out layer is defined.

Introduction of Components and Networks

Components and networks are introduced.

Component Layout

The layout and routing of components have a great impact on the product life, stability, และความเข้ากันได้ของแม่เหล็กไฟฟ้า, which should be paid special attention to. พูดโดยทั่วไป, there should be some principles as follows:

- Placing sequence:

- Place the components related to the structure in fixed positions, such as power socket, indicator light, switch, connector, ฯลฯ.

- Lock these devices with the lock function of software to prevent accidental movement.

- Place special components and large components on the circuit, such as heating elements, transformers, ไอซี, ฯลฯ.

- ในที่สุด, place small devices.

- Heat dissipation:

- Pay special attention to heat dissipation in the layout of components.

- For high-power circuits, place heating elements such as power tubes and transformers as far away as possible to facilitate heat dissipation.

- Avoid concentrating high capacitance too close to prevent premature aging of electrolyte.

Wiring

Wiring considerations for the PCB.

Adjustment and Perfection

After the wiring is completed, it is necessary to adjust the text, individual components, wiring, and copper (this work should not be too early, otherwise it will affect the speed and bring trouble to the wiring), which is also for the convenience of production, debugging, and maintenance. Copper coating usually refers to using large area copper foil to fill the blank area left after wiring. GND copper foil and VCC copper foil can be laid (but in case of short circuit, it is easy to burn the device, and it is better to ground it, unless it is used to increase the conduction area of power supply to bear large current before connecting VCC). Ground wrapping usually refers to wrapping a bunch of signal wires with special requirements by two ground wires (TRAC) to prevent it from being interfered or interfering with others. If copper is used instead of ground wire, attention must be paid to whether the whole ground is connected, the current size, flow direction, and whether there are special requirements, so as to reduce unnecessary errors.

Checking and Verifying the Network

Checking and verifying the network sometimes leads to the difference between the network relationship of the board drawn and the schematic diagram due to misoperation or negligence, so it is necessary to check the network. ดังนั้น, after drawing, do not rush to the PCB manufacturer – UGPCB.

โลโก้ UGPCB

โลโก้ UGPCB