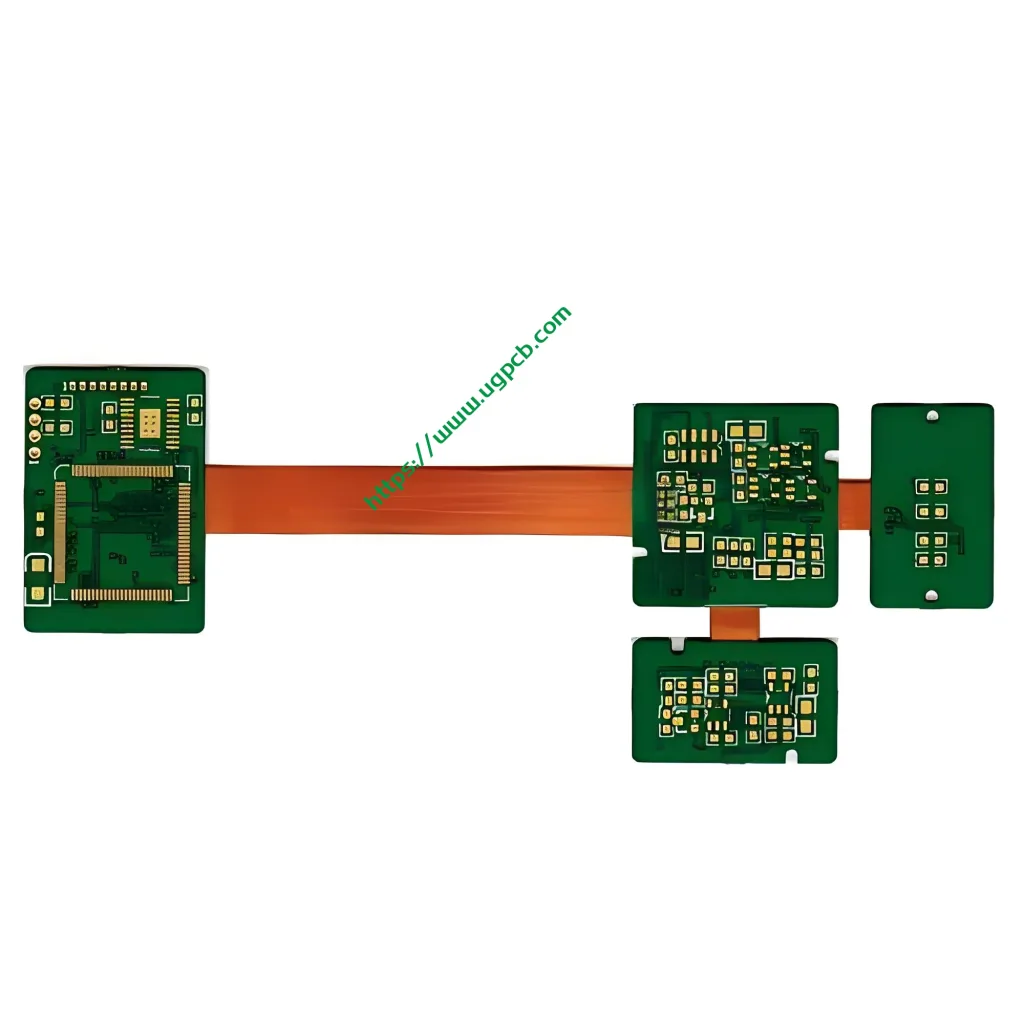

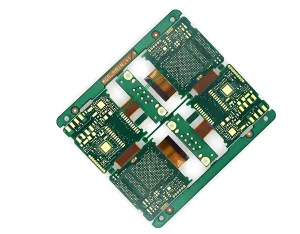

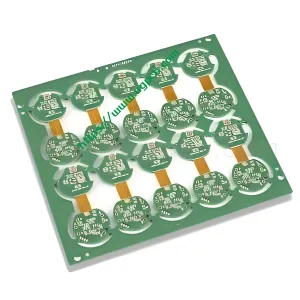

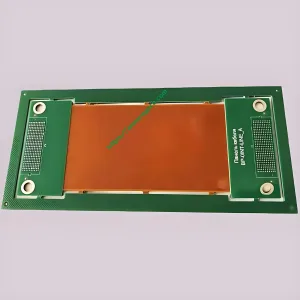

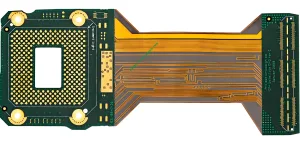

Overview of Rigid-Flex PCB (R-FPCB)

PCB แบบแข็ง (R-FPCB) is a board type that combines the advantages of rigid circuit boards (พีซีบี) and flexible circuit boards (FPC). Its structure includes both rigid and flexible boards, and through advanced technology and material combinations, it realizes design flexibility and reliability, making it especially suitable for high-density applications with strict space constraints.

High Speed Rigid Flex PCB

High Speed Rigid Flex PCB is a combination of rigid and flexible circuit board designs that allow current to flow efficiently between different circuits. The unique construction of these circuits maintains low latency and distortion during high-speed signal transmission, which is critical to the performance of modern electronic devices.

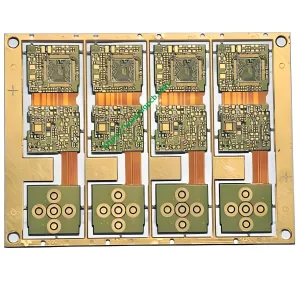

Modular Design Advantages

The modular design of high-speed rigid-flex PCB allows it to be better adapted to different applications. By designing electronic modules separately, components can be quickly replaced, simplifying the production and maintenance process and reducing assembly time and costs. This also gives designers the flexibility to choose different materials and technologies to meet specific performance requirements.

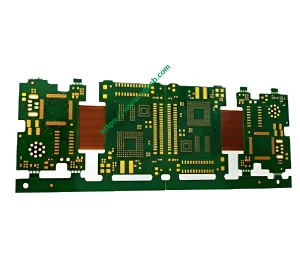

UGPCB: A High-Tech Enterprise in PCB R&D and Production

UGPCB Circuits Limited (ugpcb.com) is a high-tech enterprise focused on the R&D and production of high-end PCB. UGPCB has independently developed the PCB automatic quotation and order system, which is the first in the industry. Our final goal is to leverage Internet + technology to build a smart PCB factory of Industry 4.0, providing customers with professional PCB technology and production services.

UGPCB Products

UGPCB offers a wide range of PCB products, including:

- Radio/Microwave/Hybrid High Frequency

- FR4 Double/Multi-Layer

- 1~3+N+3 HDI

- Anylayer HDI

- Rigid-Flex

- Blind Buried

- Blind Slot

- Backdrilled

- ไอซี

- Heavy Copper Board

These PCBs are applicable in various fields such as Industry 4.0, Communication, Industrial Control, Digital, Power supply, Computer, Automotive, Medical, Aerospace, Instruments, Military, Internet, and others.

R-FPCB Specifications

PCB Surface Finishing

UGPCB offers the following surface finishing options for R-FPCB:

- OSP

- เห็นด้วย

- HASL LF

- Plated gold

- Flash gold

- Immersion Tin

- Immersion silver

- ทองแช่

Manufacturing Capacity

Our manufacturing capacity includes:

- Golden finger

- Heavy copper

- Blind buried via

- Impedance control

- Resin filling

- Carbon ink

- Backdrilling

- Countersinking

- Depth drilling

- Half-plated hole

- Pressfit hole

- Peelable blue mask

- Peelable solderstop

- Thick copper

- Oversize production

Materials

UGPCB uses a variety of materials for R-FPCB production, including:

- Taiflex

- Grace

- SY

- KB

- ITEQ

- Rogers RO4350B, RO3003, RO4003, RO3006

- RT/Duroid 5880, RT5870

- อาร์โล, Isola, เครื่องใช้แพ่ง

- PTFE F4BM, Teflon material, ฯลฯ.

Layer Counts and Dielectric Constants

UGPCB can produce R-FPCB with the following layer counts:

- 2L, 4L, 6L, 8L, 10L, 12L, 14L, 16L, 18L, 20L, 22L, 24L, 26L, 28L, 30L

And with the following dielectric constants (DK):

- 2.20, 2.55, 3.00, 3.38, 3.48, 3.50, 3.6, 6.15, 10.2

PCB Applications

UGPCB’s R-FPCB is applicable in various fields, including:

- Consumer Electronics

- Military/Space

- Antenna & Communications System

- High Power

- Medical

- Automotive

- Industrial

- Handheld Device Cellular

- Wifi Antenna

- Telematics and Infotainment

- Wifi/Computing/Radar/Power Amplifiers

โลโก้ UGPCB

โลโก้ UGPCB